Abstract

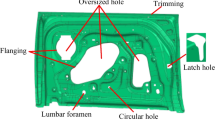

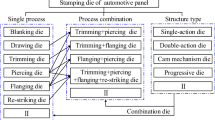

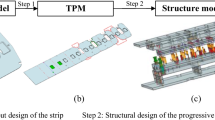

The automation and robustness have always been the focal points in the design system for stamping die. A robust methodology of automatic design based on multilevel modeling strategy is presented in this paper for automobile panel drawing die by analyzing and eliminating the factors that lead to design failure. The inherent attribute of geometry is blamed for the failure, which is defined as “ambiguous modeling failure (AMF) caused by orientation attribute.” The methodology is aimed at guaranteeing the remodel robustness and improving the automation level of die design, which is discussed under three aspects: structure modeling, die checking, and parameter managing. (1) The multilevel modeling strategy is designed to guarantee the robustness of structure modeling through treating AMFs in advance, intensively and hierarchically by redefining the modeling procedure and building two control units. (2) Automatic check of die structure is expected to drastically promote design efficiency, which will ensure checking correctness and reduce checking cost compared with manual work. (3) The well-managed parameters facilitate the invocation of parameters for the users, which make the die alterations more convenient and faster. Finally, an automated design system for automobile panel drawing die is developed on top of CATIA V5 to verify the methodology, which can accomplish the main structures, layout of standard parts, and check of die structure automatically. Experimental results and feedback from the design office together indicate that the system can improve design efficiency and design quality dramatically.

Similar content being viewed by others

References

Lee RS, Hsu QC, Su SL (1999) Development of a parametric computer-aided die design system for cold forging. J Mater Process Technol 91:80–89

Chu CH, Song MC, Luo Vincent CS (2006) Computer aided parametric design for 3D tire mold production. Comput Ind 57:11–25

Kim CW, Park CH, Lee SS (2007) An automated design system of press die components using 3-D CAD library. Computational Science and Its Applications–ICCSA 4706:961–974. doi:10.1007/978-3-540-74477-1_86

David P, Dolsak B, Miran ULBIN (2013) GAJA: 3D CAD methodology for developing a parametric system for the automatic (re)modeling of the cutting components of compound washer dies. Journal of Zhejiang University-SCIENCE A 14:327–340. doi:10.1631/jzus.A1200245

Hussein HMA (2014) Computer aided blanking die design using CATIA. Procedia CIRP 18:96–101. doi:10.1016/j.procir.2014.06.114

Naranje V, Kumar S (2014) A knowledge based system for automated design of deep drawing die for axisymmetric parts. Expert Syst Appl 41:1419–1431

Shailendra K, Rajender S (2007) An intelligent system for automatic modeling of progressive die. J Mater Process Technol 194:176–183. doi:10.1016/j.jmatprotec.2007.04.105

Kumar S, Singh R (2011) An automated design system for progressive die. Expert Systems with Application 38:4482–4489. doi:10.1016/j.eswa.2010.09.121

Jia ZX, Li HL, Zhang XC, Wu HB, Fang MC (2010) Study on the correlated design method of plate holes for progressive dies based on functional feature. Int J Adv Manuf Technol 49:1–12. doi:10.1007/s00170-009-2371-6

Jia ZX, Li HL, Zhang XC, Li JQ, Chen BJ (2011) Computer-aided structural design of punches and dies for progressive die based on functional component. Int J Adv Manuf Technol 54:837–852. doi:10.1007/s00170-010-3006-7

Lin B-T, Kun-Min H, Kuang-Yu S, Cheng-Yi H (2013) Development of an automated structural design system for progressive dies. Int J Adv Manuf Technol 68:1887–1899. doi:10.1007/s00170-013-4986-x

Lin B-T, Chian-Kun C, Wang J-C (2008) A knowledge-based parametric design system for drawing dies. Int J Adv Manuf Technol 36:671–680. doi:10.1007/s00170-006-0882-y

Bor-Tsuen L, Cheng-Yi H (2008) Automated design system for drawing dies. Expert Systems with Application 34:1586–1598. doi:10.1016/j.eswa.2007.01.024

Bor-Tsuen L, Ming-Ren C, Hau-Luen H (2009) Computer-aided structural design of drawing dies for stamping processes based on functional features. Int J Adv Manuf Technol 42:1140–1152. doi:10.1007/s00170-008-1670-7

Yilin Wang, Xiangang Hu (2011) Research on template-based parameterized structure design for drawing dies. 2012 Third International Conference on Digital Manufacturing & Automation 00:1022–1025. doi:10.1109/ICDMA.2011.253

Roller D (1991) An approach to computer-aided parametric design. Comput Aided Des 23:385–391. doi:10.1016/0010-4485(91)90033-S

Shah JJ (1991) Assessment of features technology. Comput Aided Des 23:331–343. doi:10.1016/0010-4485(91)90027-T

Solano L, Brunet P (1994) Constructive constraint-based model for parametric CAD systems. Comput Aided Des 26:614–621. doi:10.1016/0010-4485(94)90104-X

Landers DM, Khurana P (2004) Horizontally-structured CAD/CAM modeling for virtual concurrent product and process design. US Patent 6(775):581

Bodein Y, Rose B, Caillaud E (2014) Explicit reference modeling methodology in parametric CAD system. Comput Ind 65:136–147

Gebhard R (2013) “A resilient modeling strategy” technical presentation. Solid Edge University

Hui W, Dong X, Guanghong D, Linxuan Z (2007) Assembly planning based on semantic modeling approach. Comput Ind 58:227–239

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, Y., Wang, Z., Zhang, Z. et al. Robust methodology of automatic design for automobile panel drawing die based on multilevel modeling strategy. Int J Adv Manuf Technol 91, 4203–4217 (2017). https://doi.org/10.1007/s00170-017-0082-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0082-y