Abstract

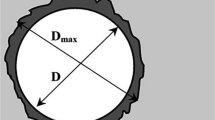

Despite the importance of the polyphthalamide (PPA) composites in many industrial applications, especially for automotive industry, very little is known about the machinability of these composites. This paper presents the drilling characteristics of PPA matrix composite materials having glass fiber of 30 % reinforced by using HSS, TiN-coated HSS, and carbide drills. The influence of cutting parameters, for example cutting speed and feed rate, on the delamination factor and surface roughness of the composites has been examined during the drilling operations. Experimental results have demonstrated that as cutting speed increases, surface roughness decreases, and as feed rate increases, surface roughness increases as well. Higher cutting speeds and lower feed rates generate better surface quality. The drilling test results have demonstrated that the delamination factor increases through the increase of feed rate and decreases through the increase of cutting speed. It is obtained the best results of the delamination factor at higher cutting speeds and lower feed rates. The machined surface is examined by means of scanning electron microscopy (SEM). SEM images of the machined surfaces show the presence of cracks, fiber pullout, and shearing of fibers.

Similar content being viewed by others

References

Brinksmeier E (1990) Prediction of tool fracture in drilling. Ann CIRP 39:97–100

Nobre JP, Stiffel JH, Nau A, Outeiro JC, Batista AC, Van Paepegem W, Scholtes B (2013) Induced drilling strains in glass fibre reinforced epoxy composites. CIRP ANN - Manufact Tech 62:87–90

Jawahir IS, Brinksmeier E, M’Saoubi R, Aspinwall DK, Outeiro JC, Meyer D, Umbrello D, Jayal AD (2011) Surface integrity in material removal processes: recent advances. CIRP Ann – Manufact Tech 60(2):603–626

El-Sonbaty I, Khashaba UA, Machaly T (2004) Factors affecting the machinability of GFR/epoxy composites. Compos. Structur 63:329–338

Kilickap E (2010) Optimization of cutting parameters on delamination based on Taguchi method during drilling of GFRP composite. Expert Syst Appl 37:6116–6122

Davim JP, Reis P, Conceição C (2004) Drilling fiber reinforced plastics (FRP) manufactured by hand-layup influence of matrix (VIAPAL VUP 9731 and ATLAC 382-05). J. Mater. Process. Tech 155-156:1828–1833

Hocheng H, Tsao CC (2003) Comprehensive analysis of delamination in drilling of composite materials with various drill bits. J Mater Process Tech 140:335–339

Ogawa K, Aoyama E, Inoue H, Hirogaki T, Nobe H, Kitahara Y, Katayama T, Gunjima M (1997) Investigation on cutting mechanism in small diameter drilling for GFRP (thrust force and surface roughness at drilled hole wall). Compos Structur 38:343–350

Lin SC, Chen IK (1996) Drilling carbon fiber-reinforced composite material at high speed. Wear 194:156–162

Cousin T, Galy J, Dupuy J (2012) Molecular modelling of polyphthalamides thermal properties: comparison between modelling and experimental results. Polymer 53(15):3203–3210

Ramkumar J, Malhotra SK, Krishnamurthy R (2002) Studies on drilling of glass/epoxy laminates using coated high-speed steel drills. Mater Manuf Process 17:213–222

Palanikumar K, Latha B, Senthilkumar V, Paulo DJ (2012) Analysis on drilling of glass fiber–reinforced polymer (GFRP) composites using Grey relational analysis. Mater Manuf Process 27:297–305

Rajamurugan TV, Shanmugam K, Palanikumar K (2013) Analysis of delamination in drilling glass fiber reinforced polyester composites. Mater Design 45:80–87

Sunny T, Babu J, Jose P (2014) Experimental studies on effect of process parameters on delamination in drilling GFRP composites using Taguchi method. Proc Mater Sci 6:1131–1142

Campos Rubio J, Abrao AM, Faria PE, Esteves Correia A, Paulo Davim J (2008) Effects of high speed in the drilling of glass fibre reinforced plastic: evaluation of the delamination factor. IJ Mach Tool Manufact 48:715–720

Gaitonde VN, Karnik SR, Davim JP (2008) Prediction and minimization of delamination in drilling of medium-density fiberboard (MDF) using response surface methodology and Taguchi design. Mater Manuf Process 23:377–384

Gaitonde VN, Karnik SR, Davim JP (2008) Taguchi multiple-performance characteristics optimization in drilling of medium density fiberboard (MDF) to minimize delamination using utility concept. J MaterProcess Technol 196:73–78

Rajamurugan TV, Shanmugam K, Palanikumar K (2013) Analysis of delamination in drilling glass fiber reinforced polyester composites. Mater Design 45:80–87

Hocheng H, Pwu HY, Yao KC (1993) Machinability of some fiber-reinforced thermoset and thermoplastics in drilling. Mater Manufact Process 8(6):653–682

El-Sonbaty I, Khashaba UA, Machaly T (2004) Factors affecting the machinability of GFR/epoxy composites. Compos Struct 63:329–338

Rajamurugan TV, Shanmugam K (2011) Optimization of machining parameters for drilling GFR polyester composites. J Emerg Sci Technol 2:31–39

Ogawa K, Aoyama E, Inoue H, Hirogaki T, Nobe H, Kitahara Y, Katayama T, Gunjima M (1997) Investigation on cutting mechanism in small diameter drilling for GFRP (thrust force and surface roughness at drilled hole wall). Compos Struct 38(1–4):343–350

Paulo Davim J, Mata F (2005) Optimisation of surface roughness on turning fibre-reinforced plastics (FRPs) with diamond cutting tools. Int J Adv Manuf Technol 26:319–323

Paulo Davim J, Leonardo R, Silva AF, Abrão AM (2009) Machinability study on precision turning of PA66 polyamide with and without glass fiber reinforcing. Mater Design 30:228–234

Palanikumar K (2007) Modeling and analysis for surface roughness in machining glass fibre reinforced plastics using response surface methodology. Mater Design 28:2611–2618

Palanikumar K, Karunamoorthy L, Karthikeyan R (2006) Assessment of factors influencing surface roughness on the machining of glass fiber-reinforced polymer composites. Mater Design 27:862–871

Paulo Davim J, Pedro R, Conceiçao António C (2004) Experimental study of drilling glass fiber reinforced plastics (GFRP) manufactured by hand lay-up. Compos Sci Tech 64:289–297

Petropoulos G, Mata F, Davim JP (2008) Statistical study of surface roughness in turning of PEEK composites. Mater Design 29:218–223

Paulo Davim J, Pedro R (2004) Machinability study on composite (polyetheretherketone reinforced with 30 % glass fibre–PEEK GF 30) using polycrystalline diamond (PCD) and cemented carbide (K20) tools. Int J Adv Manuf Technol 23:412–418

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ficici, F., Ayparcasi, Z. & Unal, H. Influence of cutting tool and conditions on machinability aspects of polyphthalamide (PPA) matrix composite materials with 30 % glass fiber reinforced. Int J Adv Manuf Technol 90, 3067–3073 (2017). https://doi.org/10.1007/s00170-016-9626-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9626-9