Abstract

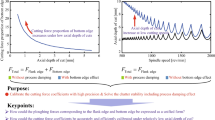

In this paper, a new model for the cutting force during the bandsawing process is presented by studying its steady and dynamic properties. Considering the sawing and no-sawing states, a single-tooth cutting force model with steady behavior was built. Then, this model was optimized by considering the intermittent feed motion of the bandsaw frame and the instantaneous chip thickness. Finally, a universal dynamic multi-tooth cutting force model with variable tooth pitch was obtained by introducing three periodic characteristics, i.e., single tooth, tooth set, and bandsaw blade transmission. Simulations and experiments verified the proposed model for intermittent feed motion, steady-state characteristics conditions, and cutting force dynamics. The errors in three characteristic frequencies between the simulations and experiments in the cutting force signal were less than 0.059 Hz. Moreover, the dynamic characteristics of the cutting force were primarily affected by the number of sawing teeth that engaged in sawing, intermittent feed motion, and variations in tooth pitch. In addition, the cutting force was approximately proportional to the number of teeth engaged in sawing, and three periodic characteristics of the cutting force were found to be common in the bandsawing process.

Similar content being viewed by others

References

Sarwar M, Haider J (2010) Aspects of burr formation in bandsaw teeth manufactured by milling operation. Robot Comput-Integr Manuf 26(6):596–601

Sarwar M, Persson M, Hellbergh H, Haider J (2009) Measurement of specific cutting energy for evaluating the efficiency of bandsawing different workpiece materials. Int J Mach Tools Manuf 49(12–13):958–965

Asiltürk İ, Ünüvar A (2009) Intelligent adaptive control and monitoring of band sawing using a neural-fuzzy system. J Mater Process Technol 209(5):2302–2313

Ni J, Xia ZN (2013) Adaptive generalized predictive control on electro hydraulic servo feeding system of band saw. Appl Mech Mater 433-435(3):1947–1952

Le-Ngoc L, McCallion H (1999) Self-induced vibration of bandsaw blades during cutting. Proc Inst Mech Eng C-J Mech E 213(4):371–380

Gendraud P, Roux JC, Bergheau JM (2003) Vibrations and stresses in band saws. J Mater Process Technol 135(1):109–116

Potočnik P, Thaler T, Govekar E (2013) Multisensory chatter detection in band sawing. Procedia CIRP 8:469–474

Thaler T, Potočnik P, Kopač J, Govekar E (2014) Experimental chatter characterization in metal band sawing. Strojniski Vestn-J Mech Eng 60(4):265–273

Wojnarowski J, Adamiec-Wójcik I (2005) Application of the rigid finite element method to modelling of free vibrations of a band saw frame. Mech Mach Theor 40(2):241–258

Sarwar M, Persson M, Hellbergh H (2005) Wear and failure modes in the bandsawing operation when cutting ball-bearing steel. Wear 259(7–12):1144–1150

Sarwar M, Persson M, Hellbergh H (2007) Wear of the cutting edge in the bandsawing operation when cutting austenitic 17-7 stainless steel. Wear 263(7–12):1438–1441

Saglam H (2011) Tool wear monitoring in bandsawing using neural networks and Taguchi’s design of experiments. Int J Adv Manuf Technol 55(9–12):969–982

James TP, Pearlman JJ, Saigal A (2012) Rounded cutting edge model for the prediction of bone sawing forces. J Biomech Eng 134(7):1001–1011

James TP, Pearlman JJ, Saigal A (2013) Predictive force model for haptic feedback in bone sawing. Med Eng Phys 35(11):1638–1644

Karakurt I (2014) Application of Taguchi method for cutting force optimization in rock sawing by circular diamond sawblades. Sadhana-Acad Proc Eng Sci 39(5):1055–1070

Karakurt I, Aydin G, Aydiner K (2013) Experimental and statistical analysis of cutting forceacting on diamond sawblade in sawing of granitic rocks. Proc Inst Mech Eng B-J Eng Ma 227(2):286–300

Yasitli NE, Bayram F, Unver B, Ozcelik Y (2011) Determination of reactional cutting forces on a circular sawblade machine by usling experimental studies and numerical modelling. Proc Inst Mech Eng C-J Mech E 226(3):775–784

Moradpour P, Doosthoseini K, Scholz F, Tarmian A (2013) Cutting forces in bandsaw processing of oak and beech wood as affected by wood moisture content and cutting directions. Eur J Wood Prod 71(6):747–754

Naylor A, Hackney P, Perera N, Clahr E (2012) A predictive model for the cutting force in wood machining developed using mechanical properties. Bioresources 7(3):2883–2894

Orlowski K, Ochrymiuk T, Atkins A (2014) An innovative approach to the forecasting of energetic effects while wood sawing. Drvna industrija 65(4):273–281

Orlowski KA, Ochrymiuk T, Atkins A, Chuchala D (2013) Application of fracture mechanics for energetic effects predictions while wood sawing. Wood Sci Technol 47(5):949–963

Sarwar M, Persson M, Hellbergh H, Haider J (2010) Forces, wear modes, and mechanisms in bandsawing steel workpieces. Proc Inst Mech Eng B-J Eng Ma 224(11):1655–1662

Sarwar M, Gillibrand D, Bradbury SR (1991) Forces, surface finish and friction characteristics in surface engineered single- and multiple-point cutting edges. Surf Coat Tech 49:443–450

Ko TJ, Kim HS (1999) Mechanistic cutting force model in band sawing. Int J Mach Tools Manuf 39(8):1185–1197

Andersson C (2001) Bandsawing. Part III: stress analysis of saw tooth microgeometry. Int J Mach Tools Manuf 41(2):255–263

Andersson C, Andersson MT, Stahl J-E (2001) Bandsawing. Part I: cutting force model including effects of positional errors, tool dynamics and wear. Int J Mach Tools Manuf 41(2):227–236

Andersson C, Stahl J-E, Hellbergh H (2001) Bandsawing. Part II: detecting positional errors, tool dynamics and wear by cutting force measurement. Int J Mach Tools Manuf 41(2):237–253

Song YQ, Ren YH, Zhou ZX, Huang XM, Song TJ (2016) Prediction of single-tooth sawing force based on tooth profile parameters. Int J Adv Manuf Technol 86:641–650

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Ni, J., Li, L., Al-Furjan, M.S.H. et al. Establishment and verification of a dynamic cutting force model for metal bandsawing. Int J Adv Manuf Technol 90, 2703–2712 (2017). https://doi.org/10.1007/s00170-016-9568-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9568-2