Abstract

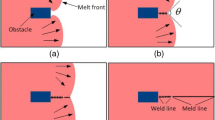

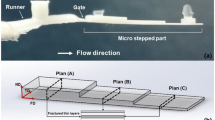

To obtain the initial conditions for ejection analysis of an injection molded part, a numerical simulation of the stress evolution in the material during injection molding is required. This topic, described in the literature only modestly for the full three-dimensional geometry, is addressed here by proposing an approach simple enough to be implemented in a general purpose solid mechanics simulation code. This feature makes it especially suitable with respect to the analysis of ejection, where custom code development might present hindering amount of additional work. As temperature and pressure field evolutions are obtainable through a computational fluid dynamics analysis, they are taken as input data in the stress analysis. The novelty of the approach is in the treatment of the melt region, where explicit tracking of the melt-solid interface is substituted by imposing the known pressure field in the melt region. The validity of the approach is experimentally tested by analyzing shrinkage and mass of moldings, as well as partial cavity pressure evolution at different packing pressure settings.

Similar content being viewed by others

References

Kennedy P (2008) Practical and scientific aspects of injection molding simulation. Technische Universiteit Eindhoven, Endhoven, The Netherlands. http://www.worldcat.org/title/practical-and-scientific-aspects-of-injection-molding-simulation/oclc/723286754

Wang H, Kabanemi KK, Salloum G (2000) Numerical and experimental studies on the ejection of injection-molded plastic products. Polym Eng Sci 40:826–840

Kabanemi KK, Vaillancourt H, Wang H, Salloum G (1998) Residual stresses, shrinkage, and warpage of complex injection molded products: numerical simulation and experimental validation. Polym Eng Sci 38:21–37. doi:10.1002/pen.10162

Pontes AJ, Pouzada AS, Pantani R, Titomanlio G (2005) Ejection force of tubular injection moldings. Part II: a prediction model. Polym Eng Sci 45:325–332. doi:10.1002/pen.20275

Jansen KMB, Titomanlio G (1996) Effect of pressure history on shrinkage and residual stresses—injection molding with constrained shrinkage. Polym Eng Sci 36:2029–2040

Bataineh OM, Klamecki BE (2005) Prediction of local part-mold and ejection force in injection molding. J Manuf Sci Eng-Trans Asme 127:598–604

Marson S, Attia UM, Lucchetta G et al (2011) Flatness optimization of micro-injection moulded parts: the case of a PMMA microfluidic component. J Micromechanics Microengineering 21:115024

Titomanlio G, Jansen KMB (1996) In-mold shrinkage and stress prediction in injection molding. Polym Eng Sci 36:2041–2049

Bushko WC, Stokes VK (1996) Solidification of thermoviscoelastic melts. Part 4: effects of boundary conditions on shrinkage and residual stresses. Polym Eng Sci 36:658–675. doi:10.1002/pen.10454

Baaijens FPT (1991) Calculation of residual stresses in injection molded products. Rheol Acta 30:284–299. doi:10.1007/BF00366642

Chang R-Y, Chiou S-Y (1995) A unified K-BKZ model for residual stress analysis of injection molded three-dimensional thin shapes. Polym Eng Sci 35:1733–1747

Kamal MR, Lai-Fook RA, Hernandez-Aguilar JR (2002) Residual thermal stresses in injection moldings of thermoplastics: a theoretical and experimental study. Polym Eng Sci 42:1098–1114

Kang SY, Kim SK, Lee WI (2008) Penalty formulation for postfilling analysis during injection molding. Int J Numer Methods Fluids 57:139–155. doi:10.1002/fld.1630

Li X, Ouyang J, Li Q, Ren J (2012) Simulations of a full three-dimensional packing process and flow-induced stresses in injection molding. J Appl Polym Sci 126:1532–1545. doi:10.1002/app.36648

Spina R, Spekowius M, Dahlmann R, Hopmann C (2014) Analysis of polymer crystallization and residual stresses in injection molded parts. Int J Precis Eng Manuf 15:89–96. doi:10.1007/s12541-013-0309-2

Zheng R, Tanner RI, Fan X-J (2011) Injection molding. Springer Berlin Heidelberg, Berlin, Heidelberg

Jansen KMB, Van Dijk DJ, Husselman MH (1998) Effect of processing conditions on shrinkage in injection molding. Polym Eng Sci 38:838–846

Jansen KMB, van Dijk DJ, Burgers EV (1998) Experimental validation of shrinkage predictions for injection molded products. Int Polym Process 13:99–104. doi:10.3139/217.980099

Vietri U, Sorrentino A, Speranza V, Pantani R (2011) Improving the predictions of injection molding simulation software. Polym Eng Sci 51:2542–2551. doi:10.1002/pen.22035

Zoetelief WF, Douven LFA, Housz AJI (1996) Residual thermal stresses in injection molded products. Polym Eng Sci 36:1886–1896. doi:10.1002/pen.10585

Aho J, Syrjälä S (2008) On the measurement and modeling of viscosity of polymers at low temperatures. Polym Test 27:35–40. doi:10.1016/j.polymertesting.2007.08.004

Pantani R, Speranza V, Titomanlio G (2001) Relevance of mold-induced thermal boundary conditions and cavity deformation in the simulation of injection molding. Polym Eng Sci 41:2022–2035

Pouzada AS, Ferreira EC, Pontes AJ (2006) Friction properties of moulding thermoplastics. Polym Test 25:1017–1023. doi:10.1016/j.polymertesting.2006.06.009

Dawson A, Rides M, Nottay J (2006) The effect of pressure on the thermal conductivity of polymer melts. Polym Test 25:268–275. doi:10.1016/j.polymertesting.2005.10.001

CJ Y, Sunderland JE, Poli C (1990) Thermal contact resistance in injection molding. Polym Eng Sci 30:1599–1606. doi:10.1002/pen.760302408

Delaunay D, Le Bot P, Fulchiron R et al (2000) Nature of contact between polymer and mold in injection molding. Part I: influence of a non-perfect thermal contact. Polym Eng Sci 40:1682–1691. doi:10.1002/pen.11300

Jansen KMB, Pantani R, Titomanlio G (1998) As-molded shrinkage measurements on polystyrene injection molded products. Polym Eng Sci 38:254–264. doi:10.1002/pen.10186

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krebelj, K., Mole, N. & Štok, B. Three-dimensional modeling of the stress evolution in injection molded parts based on a known melt pressure field. Int J Adv Manuf Technol 90, 2363–2376 (2017). https://doi.org/10.1007/s00170-016-9533-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9533-0