Abstract

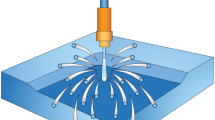

Shot peening is a mechanical surface treatment widely used in the automotive and aerospace industries to improve the fatigue performance of metallic parts. This treatment extends the fatigue life by (i) retarding the crack growth due to the induced compressive residual stresses and (ii) inhibiting the crack initiation through the surface work hardening. However, the effect of shot peening on the fatigue performance is mainly influenced by the choice of the process’s parameters. The aim of this research paper is to propose a simple methodology for optimizing the shot-peening surface’s process parameters taking into account the redistribution of the initial shot-peening properties after cyclic loading. For this purpose, the response surface methodology coupled with finite element analysis is implemented. Moreover, the effects of shot velocity, shot diameter, and peening coverage (duration of treatment) and their interactions on the fatigue performance of shot-peened parts subjected to cyclic loadings are discussed. This analysis can be considered as a very helpful tool for designer engineers in shot-peening parameter optimization.

Similar content being viewed by others

References

Society of Automotive Engineers Handbook, SAE Publications, 1964.

O’Hara P (1984) Developments in the shot peening process. Mater Des 5(4):161–166

Fathallah R, Sidhom H, Braham C, Castex L (2003) Effect of surface properties on high cycle fatigue behavior of a shot peened ductile steel. Mater Sci Technol 19:1050–1056

Gentil B, Desvignes M, Castex L (1987) Analyse des surfaces grenaillées: Fissuration, rugosité et contraintes résiduelle. Matériaux et Techniques 75:493–497

Eleiche AM, Megahed MM, Add-allah NM (2001) The shot peening effect on the HCF behavior of high-strength martensitic steels. J Mater Process Technol 113:502–508

De los Rios ER, Trull M, Levers A (2000) Modelling fatigue crack growth in shot peened components of Al 2024-T351. Fatigue Fract Eng Mater Struct 23:709–716

Guagliano M, Vergani L (2004) An approach for prediction of fatigue strength of shot peened components. Eng Fract Mech 71:501–512

Dorr T, Hilpert, Beckmerhagan MP, Kiefer A, Wagner L (1999) Influence of shot peening on fatigue performance of high-strength aluminum-and magnesium alloys. Proceedings of the ICSP-7 conference, Warsaw

Obata. M, Sudo. A (1993) Effect of shot peening on residual stress and stress corrosion cracking for cold worked austenitic stainless steel. Proceedings of the ICSP-5 conference, Oxford

Shivpuri R, Cheng X, Mao Y (2009) Elasto-plastic pseudo-dynamic numerical model for the design of shot peening process parameters. Mater Des 30:3112–3120

Rodopoulos CA, Curtis SA, de los Rios ER, SolisRomero J (2004) Optimisation of the fatigue resistance of 2024-T351 aluminium alloys by controlled shot peeningmethodology results and analysis. Int J Fatigue 26:849–856

Mahagaonkar SB, Brahmankar PK, Seemikeri CY (2008) Effect of shot peening parameters on microhardness of AISI 1045 and 316L material: an analysis using design of experiment. Int J Adv Manuf Technol 38:563–574

Ahmed AA, Mhaede M, Basha M, Wollmann M, Wagner L (2015) The effect of shot peening parameters and hydroxyapatite coating on surface properties and corrosion behavior of medical grade AISI 316L stainless steel. Surface & Coatings Technology 280:347–358

Nam YS, Jeong YI, Shin BC, Byun JH (2015) Enhancing surface layer properties of an aircraft aluminum alloy by shot peening using response surface methodology. Mater Des 83:566–576

Torres MAS, Voorwald HJC (2002) An evaluation of shot peening residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int J Fatigue 24:877–886

Dalaei K, Karlsson B, Svensson LE (2011) Stability of residual stresses created by shot peening of pearlitic steel and their influence on fatigue lifetime. Mater Sci Eng A 5282:1008–1015

Denkena B, Köhler J, Breidenstein B, Mörke T (2011) Elementary studies on the inducement and relaxation of residual stress. Procedia Eng 19:88–93

Liu J, Yuan H (2010) Prediction of residual stress relaxations in shot-peened specimens and its application for the rotor disc assessment. Mater Sci Eng A 527:6690–6698

Zaroog OS, Aidy A, Sahari BB, Zahari R (2011) Modeling of residual stress relaxation of fatigue in 2024-T351 aluminium alloy. Int J Fatigue 33:279–285

Xie L, Wen Y, Zhan K, Wang L, Jiang C, Ji V (2016) Characterization on surface mechanical properties of Tie6Ale4V after shot peening. J Alloys Compd 666:65–70

Zhuang WZ, Halford GR (2001) Investigation of residual stress relaxation under cyclic load. Int J Fatigue 23:31–37

Seungho H, Lee T, Shin B (2002) Residual stress relaxation of welded steel components under cyclic load. Mater Technol (Steel Res) 73:414–420

Maximov JT, Duncheva GV, Mitev IN (2009) Modeling of residual stress relaxation around cold expanded holes in carbon steel. J Constr Steel Res 65:909–917

Zaroog OS, Aidy A, Sahari BB, Zahari R (2009) Modeling of residual stress relaxation: a review. J Sci Technol 17:211–218

Arbab Chirani, S (1998) Méthodologie pour la prise en compte des contraintes résiduelles dans un calcul prévisionnel de durée de vie en fatigue de pièces en aluminium. PhD thesis. France: Université de Technologie de Compiègne

Gong K, Milley A, Lu, J (2001). Design tool on fatigue for 3D components with consideration of residual stresses. SAE 2001 World Congress, Fatigue Research & Applications (Part A&B), Detroit, MI, USA, 1–6

Smith DJ, Farrahi GH, Zhu WX, McMahon CA (2001) Experimental measurement and finite element simulation of the interaction between residual stresses and mechanical loading. Int J Fatigue 23:293–302

Boyce BL, Chen X, Peters JO, Hutchinson JW, Ritchie RO (2003) Mechanical relaxation of localized residual stresses associated with foreign object damage. Mater Sci Eng A349:48–58

Frija M, Hassine T, Fathallah R, Bouraoui C, Dogui A (2006) FEM modelling of shot peening process: prediction of the compressive residual stresses, the plastic deformations and the surface integrity. Mater Sci Eng 426:173–180

Miao HY, Larose S, Perron C, Lévesque M (2009) On the potential applications of a 3D random finite element model for the simulation of shot peening. Adv Eng Softw 40:1023–1038

Myers RH, Montgomery DC (2002) Response surface methodology, 2nd edn. Wiley, New York

Kartal ME, Basaga HB, Bayraktar A (2011) Probabilistic nonlinear analysis of CFR dams by MCS using response surface method. Appl Math Model 35:2752–2770

Zahraee SM, Hatami M, Yusof NM, Rohani M, Ziaei F (2013) Combined use of design of experiment and computer simulation for resources level determination inconcrete pouring process. Jurnal Teknologi 64(1):43–49

Montgomery D (2009) Basic experiment design for process improvement statistical quality control. Wiley, USA

ABAQUS Theory Manual (2011) Version 6.10. Hibbitt, Karlsson and Sorensen Inc, USA

Taehyung K, Hyungyil L, Minsoo K, Sunghwan J (2012) A 3D FE model with plastic shot for evaluation of equi-biaxial peening residual stress due to multi-impacts. Surf Coat Technol 206:3981–3988

Gariépy A, Larose S, Perron C, Lévesque M (2011) Shot peening and peen forming finite element modelling—towards a quantitative method. Int J Solids Struct 48:2859–2877

R. Fathallah (1994). Modélisation du Procédé de Grenaillage: Incidence des Billes et Taux de Recouvrement. PhD thesis ENSAM Paris

Armstrong, P.J and Frederick, C.O (1966). A mathematical representation of the multi-axial Bauschinger effect. Technical Report RD/B/N731, CEGB

Chaboche J-L (1977). Sur l’utilisation des variables d’état interne pour la description de la viscoplasticité cyclique avec endommagement. In Problèmes Non Linéaires de Mécanique, Symposium Franco-Polonais de Rhéologie et Mécanique, 137–159

Lemaitre J, Chaboche, J.L (2002). Mécanique des matériaux solides. Dunod (Edition 2), ISBN 2 10 005662X

Sidhom N, Laamouri A, Fathallah R, Braham C, Lieurade H (2005) Fatigue strength improvement of 5083 H11 Al-alloy T-welded joints by shot peening: experimental characterization and predictive approach. Int J Fatigue 27:729–745

Wagner L (1999) Mechanical surface treatments on titanium, aluminum and magnesium alloys. Mater Sci Eng A 263:210–216

ISO 4287 (1997). Geometrical product specifications (GPS), surface texture: profile method-terms, definitions and surface texture parameters. Ed. International Organization for Standardization (ISO)

Laamouri A, Sidhom H, Braham C (2013) Evaluation of residual stress relaxation and its effect on fatigue strength of AISI 316L stainless steel ground surfaces: experimental and numerical approaches. Int J Fatigue 48:109–121

Sanjurjo P, Rodríguez C, Peñuelas I, García TE, Javier Belzunce F (2014) Influence of the target material constitutive model on the numerical simulation of a shot peening process. Surface & Coatings Technology 258:822–831

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seddik, R., Bahloul, A., Atig, A. et al. A simple methodology to optimize shot-peening process parameters using finite element simulations. Int J Adv Manuf Technol 90, 2345–2361 (2017). https://doi.org/10.1007/s00170-016-9532-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9532-1