Abstract

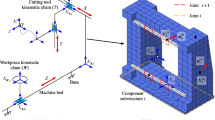

The usage of virtual prototype technology to study the static and dynamic properties of machine tools could shorten the life cycle time of machine design as there is no need for a physical prototype. The base of this technology is to establish the virtual model accurately and conveniently. This study presents a hybrid analytic-experimental method for the dynamic modeling of machine tools. In the proposed method, the structural components of machine tools are modeled by an analytic method (finite element method), and the machine elements are represented by models that originate from experimental data. The full dynamic model of the machine tool structure is obtained by assembling the analytic models of the structural components and experimental models of the machine elements. The bolted joint is taken as an example to illustrate the experimental model for the machine elements and the assembly of the analytic and experimental models. The convenience and accuracy of the proposed hybrid analytic-experimental modeling method are illustrated by two engineering examples.

Similar content being viewed by others

References

Altintas Y, Brecher C, Weck M, Witt S (2005) Virtual machine tool. CIRP Ann Manuf Technol 54(2):115–138

Vesely J, Sulitka M (2008) Machine tool virtual model. In International Congress Matar Praha, 115–122

Brecher C, Esser M, Witt S (2009) Interaction of manufacturing process and machine tool. CIRP Ann Manuf Technol 58(2):588–607

Brecher C, Witt S (2009) Interactive analysis of the structural mechanic behaviour of machine tools. Prod Eng 3(4-5):475–481

Lee RS, Lin YH (2010) Development of universal environment for constructing 5-axis virtual machine tool based on modified D–H notation and OpenGL. Robot Comput Integr Manuf 26(3):253–262

Kadir AA, Xu X, Hämmerle E (2011) Virtual machine tools and virtual machining—a technological review. Robot Comput Integr Manuf 27(3):494–508

Ding WZ, Huang XD, Wang ML, Zhu SQ (2013) An approach to evaluate the effects of nonlinear traveling joints on dynamic behavior of large machine tools. Int J Adv Manuf Technol 68(9):2025–2032

Zatarain M, Lejardi E, Egana F, Bueno R (1998) Modular synthesis of machine tools. CIRP Ann Manuf Technol 47(1):333–336

Tlusty J, Ziegert JC, Ridgeway S (2000) A comparison of stiffness characteristics of serial and parallel machine tools. J Manuf Process 2(1):67–76

Huang DT-Y, Lee J-J (2001) On obtaining machine tool stiffness by CAE techniques. Int J Mach Tools Manuf 41(8):1149–1163

Doman D, Warkentin A, Bauer R (2009) Finite element modeling approaches in grinding. Int J Mach Tools Manuf 49(2):109–116

Bais R, Gupta A, Nakra B, Kundra T (2004) Studies in dynamic design of drilling machine using updated finite element models. Mech Mach Theory 39(12):1307–1320

Ford DG, Widiyarto MHN, Myers A, Longstaff AP, Fletcher S (2014) Structural analysis and characterisation technique applied to a CNC vertical machining centre. Proc Inst Mech Eng C J Mech Eng Sci 228(13):2357–2371

Liang Y, Chen W, Bai Q, Sun Y, Chen G, Zhang Q, Sun Y (2013) Design and dynamic optimization of an ultraprecision diamond flycutting machine tool for large KDP crystal machining. Int J Adv Manuf Technol 69(1):237–244

Huo D, Cheng K, Wardle F (2010) Design of a five-axis ultra-precision micro-milling machine—UltraMill. Part 2: integrated dynamic modelling, design optimisation and analysis. Int J Adv Manuf Technol 47(9):879–890

Aurich JC, Biermann D, Blum H, Brecher C, Carstensen C, Denkena B, Klocke F, Kröger M, Steinmann P, Weinert K (2009) Modelling and simulation of process: machine interaction in grinding. Prod Eng 3(1):111–120

Fleischer J, Munzinger C, Tröndle M (2008) Simulation and optimization of complete mechanical behaviour of machine tools. Prod Eng 2(1):85–90

Brecher C, Witt S (2006) Simulation of machine process interaction with flexible multi-body simulation. In Proceedings of the 9th CIRP international workshop on modeling of machining operations, Bled, Slovenia, 171–178

Cano T, Chapelle F, Lavest J-M, Ray P (2008) A new approach to identifying the elastic behaviour of a manufacturing machine. Int J Mach Tools Manuf 48(14):1569–1577

Zhang G, Huang Y, Shi W, Fu W (2003) Predicting dynamic behaviours of a whole machine tool structure based on computer-aided engineering. Int J Mach Tools Manuf 43(7):699–706

Renton D, Elbestawi M (2001) Motion control for linear motor feed drives in advanced machine tools. Int J Mach Tools Manuf 41(4):479–507

Zaeh M, Siedl D (2007) A new method for simulation of machining performance by integrating finite element and multi-body simulation for machine tools. CIRP Ann Manuf Technol 56(1):383–386

Taylor S, Tobias S (1964) Lumped-constants method for the prediction of the vibration characteristics of machine tool structures. In Proc 5th Int MTDR Conf

Hijink J, Van Der Wolf A (1974) Analysis of a milling machine: computed results versus experimental data. In Proceedings of the fourteenth international machine tool design and research conference 553–558

Beards C (1982) Damping in structural joints. Shock Vib Inf Center Shock Vib Dig 14(6):9–11

Tlusty J, Ismail F (1980) Dynamic structural identification tasks and methods. CIRP Ann Manuf Technol 29(1):251–255

Ahmadian H, Jalali H (2007) Identification of bolted lap joints parameters in assembled structures. Mech Syst Signal Process 21(2):1041–1050

Tian H, Li B, Liu H, Mao K, Peng F, Huang X (2011) A new method of virtual material hypothesis-based dynamic modeling on fixed joint interface in machine tools. Int J Mach Tools Manuf 51(3):239–249

Mao K, Li B, Wu J, Shao X (2010) Stiffness influential factors-based dynamic modeling and its parameter identification method of fixed joints in machine tools. Int J Mach Tools Manuf 50(2):156–164

Shamine DM, Shin YC (2000) Analysis of no. 50 taper joint stiffness under axial and radial loading. J Manuf Process 2(3):167–173

Namazi M, Altintas Y, Abe T, Rajapakse N (2007) Modeling and identification of tool holder–spindle interface dynamics. Int J Mach Tools Manuf 47(9):1333–1341

Xu C, Zhang J, Wu Z, Yu D, Feng P (2013) Dynamic modeling and parameters identification of a spindle–holder taper joint. Int J Adv Manuf Technol 67(5–8):1517–1525

Kolar P, Sulitka M, Janota M (2011) Simulation of dynamic properties of a spindle and tool system coupled with a machine tool frame. Int J Adv Manuf Technol 54(1):11–20

Okwudire CE, Altintas Y (2009) Hybrid modeling of ball screw drives with coupled axial, torsional, and lateral dynamics. J Mech Des 131(7):071002

Vicente DA, Hecker RL, Villegas FJ, Flores GM (2012) Modeling and vibration mode analysis of a ball screw drive. Int J Adv Manuf Technol 58(1–4):257–265

Dhupia JS, Ulsoy AG, Katz R, Powalka B (2008) Experimental identification of the nonlinear parameters of an industrial translational guide for machine performance evaluation. J Vib Control 14(5):645–668

Ohta H, Tanaka K (2010) Vertical stiffnesses of preloaded linear guideway type ball bearings incorporating the flexibility of the carriage and rail. J Tribol 132(1):011102

Shaw D, Su W (2013) Stiffness analysis of linear guideways without preload. J Mech 29(02):281–286

Li H, Li B, Mao K, Huang X, Peng F (2014) A parameterized model of bolted joints in machine tools. Int J Acoust Vib 19(1):10–20

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ye, B., Xiao, W., Mao, K. et al. Hybrid analytic-experimental modeling for machine tool structural dynamics. Int J Adv Manuf Technol 90, 1679–1691 (2017). https://doi.org/10.1007/s00170-016-9507-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9507-2