Abstract

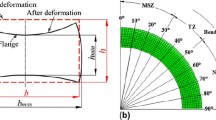

Cross-sectional deformation is one of the critical factors that affect the forming accuracy of double-ridged rectangular tube (DRRT) in E-typed rotary draw bending (RDB). In the forming process, springback is inevitable and it has a direct impact on the cross-sectional deformation. Based on ABAQUS platform, three-dimensional finite element (3D-FE) models for bending and springback of H96 brass DRRT in E-typed RDB were established. With the models, the impact of springback on the cross-sectional deformation was studied. Results show that after springback, the deformation of cross-sectional height and two ridge grooves spacing increase in cores-support zone while decrease in no-cores-support zone. The impact of springback on width deformation is not significant. The maximum values of cross-sectional height deformation and two ridge grooves spacing deformation from 0° to 30° become larger after springback, while the change rules of these two from 30° to 90° are reversed. What’s more, the maximum value of width deformation from 0° to 60° becomes larger after springback while that of outer ridge groove width deformation becomes smaller, and these two from 60° to 90° both have the reversed change rules as well.

Similar content being viewed by others

References

Wang YS (1994) The double ridge wave guide process. Electronics process technology 6:18–19 (in Chinese)

Ruan ZG (2000) The bending and twisting process of the 24JS-3500 double ridge wave guide tube. Technology and Economy Information of Shipbuilding Industry 7:41–44 (in Chinese)

Liu CM, Liu YL, Shen HW, et al. (2013) Characteristics of cross section deformation of double-ridge rectangular tube of H96 brass in rotary draw bending process. Journal of Aeronautical Materials 33(6):13–19 (in Chinese)

Liu CM, Liu YL, Ren JH, et al. (2015) Influence of die constraint on cross-sectional deformation of H96 brass double-ridged rectangular tube in E-typed rotary draw bending process. Acta Aeronautica et Astronautica Sinica 36(4):1320–1329 (in Chinese)

Zhang HL, Liu YL, Yang H (2016) Deformation behaviors of double-ridged rectangular H96 tube in rotary draw bending under different mandrel types. Int J Adv Manuf Technol 82(9-12):1569–1580. doi:10.1007/s00170-015-7468-5

Xiao YH, Liu YL, Yang H (2014) Research on cross-sectional deformation of double-ridged rectangular tube during H-typed rotary draw bending process. Int J Adv Manuf Technol 73(9-12):1789–1798. doi:10.1007/s00170-014-5968-3

Xiao YH, Liu YL, Yang H (2014) Prediction of forming limit based on cross-sectional distortion for rotary draw bending of H96 brass double-ridged rectangular tube. Int J Adv Manuf Technol 71(5-8):1445–1454. doi:10.1007/s00170-013-5552-2

Miller JE, Kyriakides S, Bastard AH (2001) On bend-stretch forming of aluminum extruded tubes-I: experiments. International Journal of Mechanical Sciences 43(5):1283–1317. doi:10.1016/S0020-7403(00)00039-4

Miller JE, Kyriakides S (2003) Three-dimensional effects of the bend-stretch forming of aluminum tubes. International Journal of Mechanical Sciences 45(1):115–140. doi:10.1016/S0020-7403(03)00036-5

Jin CH, Zhou XB, Diao KS, et al. (2004) Numerical simulation of a stretch bending process for extruded aluminum rectangular tubes. Materials Science & Technology 12(6):572–575 (in Chinese)

Jin CH, Zhou XB (2007) PS2F based on spring back in stretch wrap bending of aluminum profiles. Journal of Plasticity Engineering 14(3):1–4 (in Chinese)

Paulsen F, Welo T (2001) Cross-sectional deformations of rectangular hollow sections in bending: Part II—analytical models. International Journal Mechanical Sciences 43(1):131–152. doi:10.1016/S0020-7403(99)00107-1

Paulsen F, WeloT (2001) A Design Method for Rectangular Hollow Sections in Bending. Journal of Materials Processing Technology 113(1-3): 699-704. doi:10.1016/S0924-0136(01)00671-9

Paulsen F, Welo T (2002) A Design Method for Prediction of Dimensions of Rectangular Hollow Sections Formed in Stretch Bending. Journal of Materials Processing Technology 128(1-3):48–66. doi:10.1016/S0924-0136(02)00178-4

Corona E (2004) A Simple Analysis for Bend-stretch Forming of Aluminum Extrusion. International Journal of Mechanical Science 46(3):433–448. doi:10.1016/j.ijmecsci.2004.03.010

Zhao GY, Liu YL, Yang H, et al. (2010) Cross-sectional distortion behaviors of thin-walled rectangular tube in rotary-draw bending process. Tran. Nonferrous Met. Soc. China 20(3):484–489. doi:10.1016/S1003-6326(09)60166-7

Zhang K, Liu YL, Yang H (2013) Influence of retracting mandrel on spring back of H96 thin-walled rectangular wave-guide tube in rotary draw bending process. Materials Science & Technology 21(1):56–61 (in Chinese)

Zhu YX, Liu YL, Yang H (2012) Sensitivity of springback and section deformation to process parameters in rotary-draw bending of thin-walled rectangular H96 brass tube. Transactions of Nonferrous Metals Society of China 22(9):2233–2240. doi:10.1016/S1003-6326(11)61454-4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, X., Liu, Y., Liu, C. et al. Impact of springback on the cross-sectional deformation of H96 brass double-ridged rectangular tube in E-typed rotary draw bending . Int J Adv Manuf Technol 89, 3451–3458 (2017). https://doi.org/10.1007/s00170-016-9320-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9320-y