Abstract

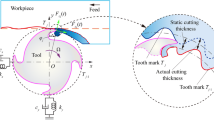

Machining chatter has detrimental effects on surface quality, tool life, and machining efficiency. Therefore, it is of vital significance to predict and avoid this undesirable phenomenon. This paper presents an Adams-Moulton-based method for the stability prediction of milling operations. Generally, delay differential equations with time-periodic coefficients are applied to model the milling dynamics that include the regenerative effect. To begin with, the tooth-passing period is divided into free vibration time period and forced vibration time period. Subsequently, the Adams-Moulton method is utilized to construct the transition matrix over one period through dividing the forced vibration time period equally into small time intervals. Finally, the milling stability can be obtained by examining the eigenvalues of the transition matrix based on Floquet theory. A comparison with the first-order semi-discretization method and the Simpson-based method is conducted to evaluate the convergence rate and the computation efficiency of the proposed algorithm. The results verify that the proposed method is highly accurate and efficient; thus, it is practical for workshop technicians to select chatter-free machining parameters.

Similar content being viewed by others

References

Tobias SA (1965) Machine tool vibration. Blackie, Glazgow

Konigsberger F, Tlusty J (1967) Machine tool structures—vol.I: stability against chatter. Pergamon, Elmsford

Altintas Y (2012) Manufacturing automation: metal cutting, mechanics, machine tool vibrations, and CNC design. Cambridge University Press, New York

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann 53(2):619–642

Altintas Y, Stepan G, Merdol D, Dombovari Z (2008) Chatter stability of milling in frequency and discrete time domain. CIRP J Manuf Sci Technol 1(1):35–44

Ding H, Ding Y, Zhu LM (2012) On time-domain methods for milling stability analysis. Chinese Sci Bull 57(33):4336–4345

Smith S, Tlusty J (1993) Efficient simulation programs for chatter in milling. CIRP Ann Manuf Techn 42:463–466

Davies MA, Pratt JR, Dutterer B, Burns TJ (2000) Stability of low radial immersion milling. CIRP Ann Manuf Techn 49:37–40

Davies MA, Pratt JR, Dutterer B, Burns TJ (2002) Stability prediction for low radial immersion milling. J Manuf Sci E-T ASME 124:217–225

Campomanes ML, Altintas Y (2003) An improved time domain simulation for dynamic milling at small radial immersions. J Manuf Sci E-T ASME 125:416–422

Li ZQ, Liu Q (2008) Solution and analysis of chatter stability for end milling in the time-domain. Chin J Aeronaut 21:169–178

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann 44(1):357–362

Merdol SD, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng 126(3):459–466

Bayly PV, Mann BP, Schmitz TL, Peters DA, Stepan G, Insperger T (2002) Effects of radial immersion and cutting direction on chatter instability in end-milling. In: Proceedings of the international mechanical engineers conference and exposition. New Orleans, Paper No.IMECE2002–39116

Butcher EA, Bobrenkov OA, Bueler E, Nindujarla P (2009) Analysis of milling stability by the Chebyshev collocation method: algorithm and optimal stable immersion levels. J Comput Nonlin Dyn 4:031003

Insperger T, Stepan G (2002) Semi-discretization method for delayed systems. Int J Numer Methods Biomed Eng 55(5):503–518

Insperger T, Stepan G (2004) Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Methods Biomed Eng 61(1):117–141

Insperger T, Stepan G, Turi J (2008) On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib 313(1):334–341

Insperger T, Stepan G (2011) Semi-discretization for time-delay systems: stability and engineering applications. Springer, New York

Dong XF, Zhang WM, Deng S (2015) The reconstruction of a semi-discretization method for milling stability prediction based on Shannon standard orthogonal basis. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7719-5

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) Second-order full-discretization method for milling stability prediction. Int J Mach Tools Manuf 50:926–932

Quo Q, Sun YW, Jiang Y (2012) On the accurate calculation of milling stability limits using third-order full-discretization method. Int J Mach Tools Manuf 62:61–66

Ozoegwu CG, Omenyi SN, Ofochebe SM (2015) Hyper-third order full-discretization methods in milling stability prediction. Int J Mach Tools Manuf 92:1–9

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Numerical integration method for prediction of milling stability. J Manuf Sci Eng 133(3):031005

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Milling stability analysis using the spectral method. Sci China Technol Sci 54(12):3130–3136

Li MZ, Zhang GJ, Huang Y (2013) Complete discretization scheme for milling stability prediction. Nonlinear Dyn 71:187–199

Xie QZ (2016) Milling stability prediction using an improved complete discretization method. Int J Adv Manuf Technol 83(5–8):815–821

Li ZQ, Yang ZK, Peng YR, Zhu F, Ming XZ (2015) Prediction of chatter stability for milling process using Runge-Kutta-based complete discretization method. Int J Adv Manuf Technol. doi:10.1007/s00170-015-8207-7

Niu JB, Ding Y, Zhu LM, Ding H (2014) Runge–Kutta methods for a semi-analytical prediction of milling stability. Nonlinear Dyn 76(1):289–304

Ding Y, Zhang XJ, Ding H (2015) A Legendre polynomials based method for stability analysis of milling processes. ASME J Vib Acoust 137(2):024504

Zhang Z, Li HG, Meng G, Liu C (2015) A novel approach for the prediction of the milling stability based on the Simpson method. Int J Mach Tools Manuf 99:43–47

Zhang XJ, Xiong CH, Ding Y, Ding H (2016) Prediction of chatter stability in high speed milling using the numerical differentiation method. Int J Adv Manuf Technol. doi:10.1007/s00170-016-8708-z

Butcher JC (2008) Numerical methods for ordinary differential equations, Second edn. John Wiley & Sons, Chichester

Peinado J, Ibáñez JE, Arias EV, Hernández V (2010) Adams-Bashforth and Adams-Moulton methods for solving differential Riccati equations. Comput Math With Appl 60(11):3032–3045

Seong HY, Majid ZA, Ismail F (2013) Solving second-order delay differential equations by direct Adams–Moulton method. Math Probl Eng 113(2):292–319

Insperger T (2010) Full-discretization and semi-discretization for milling stability prediction: some comments. Int J Mach Tools Manuf 50(7):658–662

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, C., Tao, J., Li, L. et al. An Adams-Moulton-based method for stability prediction of milling processes. Int J Adv Manuf Technol 89, 3049–3058 (2017). https://doi.org/10.1007/s00170-016-9293-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9293-x