Abstract

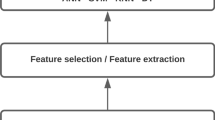

Machined surface quality and dimensional accuracy are significantly affected by tool wear in machining process, and severe tool wear may even lead to failing of the workpieces being processed. Tool wear monitoring is highly desirable to realize automated or unmanned machining process, which can get rid of the dependence on skilled workers. This paper mainly studies on the methods and techniques of on-line tool wear monitoring through static and dynamic cutting force signals. Sensitive signals related to tool wear are preliminarily selected by using correlation coefficient method. Kernel principal component analysis (KPCA) technique is adopted to fuse these sensitive features for improving training speed and prediction accuracy. Then, the tool wear predictive model based on v-support vector regression (v-SVR) is constructed through learning correlation between the fused features and actual tool wear. The obtained result shows that the prediction accuracy of the proposed tool wear model is proved effective beyond expectation. Besides, the proposed model still has better generalization ability even in small sample size.

Similar content being viewed by others

References

Jurkovic J, Korosec M, Kopac J (2005) New approach in tool wear measuring technique using CCD vision system. Int J Mach Tools Manuf 45:1023–1030

Castejón M, Alegre E, Barreiro J, Hernández LK (2007) On-line tool wear monitoring using geometric descriptors from digital images. Int J Mach Tools Manuf 47:1847–1853

Dimla DE Sr, Lister PM (2000) On-line metal cutting tool condition monitoring. I: force and vibration analyses. Int J Mach Tools Manuf 40:739–768

Salgado DR, Alonso FJ (2007) An approach based on current and sound signals for in-process tool wear monitoring. Int J Mach Tools Manuf 47:2140–2152

Choudhury SK, Rath S (2000) In-process tool wear estimation in milling using cutting force model. J Mater Process Technol 99(1):113–119

Ghosh N, Ravi YB, Patra A, Mukhopadhyay S, Paul S, Mohanty AR, et al. (2007) Estimation of tool wear during CNC milling using neural network-based sensor fusion. Mech Syst Signal Process 21:466–479

Dong J, Subrahmanyam KVR, Wong YS, Hong GS, Mohanty AR (2005) Bayesian-inference-based neural networks for tool wear estimation. Int J Adv Manuf Technol 30:797–807

Eiji S, Rei H, Masayuki U, et al. (2003) Intelligent recognition of end milling conditions based on cutting force model. Trans Jpn Soc Mech Eng C 69(7):1927–1932

Kilundu B, Dehombreux P, Chiementin X (2011) Tool wear monitoring by machine learning techniques and singular spectrum analysis. Mech Syst Signal Process 25:400–415

Kima JS, Kangb MC, Ryuc BJ, Jic YK (1999) Development of an on-line tool-life monitoring system using acoustic emission signals in gear shaping. Int J Mach Tools Manuf 39:1761–1777

Dimla DE Sr (2000) Sensor signals for tool-wear monitoring in metal cutting operations—a review of methods. Int J Mach Tools Manuf 40:1073–1098

Kaya B, Oysu C, Ertunc HM (2011) Force-torque based on-line tool wear estimation system for CNC milling of Inconel 718 using neural networks. Adv Eng Softw 42:76–84

Fish RK, Ostendorf M, Bernard GD, Castanon DA (2003) Multilevel classification of milling tool wear with confidence estimation. IEEE Trans Pattern Anal Mach Intell 25:75–85

Tobon-Mejia DA, Medjaher K, Zerhouni N (2012) CNC machine tool's wear diagnostic and prognostic by using dynamic Bayesian networks. Mech Syst Signal Process 28:167–182

Dimla DE Sr, Lister PM (2000) On-line metal cutting tool condition monitoring. II: tool-state classification using multi-layer perceptron neural networks. Int J Mach Tools Manuf 40:769–781

Chungchoo C, Saini D (2002) On-line tool wear estimation in CNC turning operations using fuzzy neural network model. Int J Mach Tools Manuf 42:29–40

Kious M, Ouahabi A, Boudraa M, Serra R, Cheknane A (2010) Detection process approach of tool wear in high speed milling. Measurement 43:1439–1446

Kamarthi SV, Pittner S (1997) Fourier and wavelet transform for flank wear estimation—a comparison. Mech Syst Signal Process 11:791–809

Shi D, Gindy NN (2007) Tool wear predictive model based on least squares support vector machines. Mech Syst Signal Process 21:1799–1814

Scheffer C, Heyns PS (2004) An industrial tool wear monitoring system for interrupted turning. Mech Syst Signal Process 18:1219–1242

Shi D, Tsung F (2003) Modelling and diagnosis of feedback-controlled processes using dynamic PCA and neural networks. Int J Prod Res 41:365–379

Schölkopf B, Smola A, Müller K (1998) Nonlinear component analysis as a kernel eigenvalue problem. Neural Comput 10(5):1299–1319

Schölkopf B, Smola AJ, Williamson RC, Bartlett PL (2000) New support vector algorithms. Neural Comput 12(5):1207–1245

J C Platt (1998) Sequential minimal optimization: a fast algorithm for training support vector machines. Microsoft Research, Technical Report MSR-TR-98-14

Platt JC (1999) Fast training of support vector machines using sequential minimal optimization," advances in kernel methods: support vector learning. MIT Press, Cambridge

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, D., Chen, Y., Li, N. et al. Tool wear monitoring based on kernel principal component analysis and v-support vector regression. Int J Adv Manuf Technol 89, 175–190 (2017). https://doi.org/10.1007/s00170-016-9070-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9070-x