Abstract

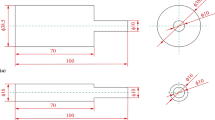

The present work reports the influence of thermal process on microstructure and mechanical behavior for friction taper plug welding (FTPW) in structural steel S355. The results indicate that there is a significant decrease in total energy input and cooling time in temperature interval from 800 to 500 °C (Δt8/5) with increasing the axial force. However, the varying axial force has little effect on the peak temperature. The microstructure of weld zone contains acicular ferrite, polygonal ferrite, grain boundary allotriomorphic ferrite, and lath bainite. With decreasing total energy input and Δt8/5, the formation of lath bainite is promoted as well as the precipitation and growth of grain boundary allotriomorphic ferrite is inhibited. The hardness tends to increase with decreasing total energy input and Δt8/5. Charpy impact energy at the bonding line is almost 35 J ± 7 J for all specimens. On the other hand, Charpy impact energy at the weld zone increases gradually with decreasing total energy input and Δt8/5.

Similar content being viewed by others

References

Faes K, Dhooge A, De Baets P, Afschrift P (2009) New friction welding process for pipeline girth welds—welding time optimisation. Int J Adv Manuf Technol 43:982–992

Sahin M (2010) Joining of aluminium and copper materials with friction welding. Int J Adv Manuf Technol 49:527–534

Kalsi NS, Sharma VS (2011) A statistical analysis of rotary friction welding of steel with varying carbon in workpieces. Int J Adv Manuf Technol 57:957–967

Wang Y, Luo J, Wang X, Xu X (2013) Interfacial characterization of T3 copper/35CrMnSi steel dissimilar metal joints by inertia radial friction welding. Int J Adv Manuf Technol 68:1479–1490

Maalekian M (2007) Friction welding—critical assessment of literature. Sci Technol Weld Join 12:738–759

Yeh FWT, Pereira da Cunha PHC, Lessa CRDL, Clarke T, Strohaecker T (2013) Evaluation of discontinuities in A36 steel repairs with friction hydro pillar processing using different axial forces. ISIJ Int 53:2269–2271

Chludzinski M, Paes MP, Bastian FL, Strohaecker TR (2012) Fracture toughness of friction hydro-pillar processing welding in C–Mn steel. Mater Des 33:340–344

Hattingh DG, Bulbring DLH, Els-Botes A, James MN (2011) Process parameter influence on performance of friction taper stud welds in AISI 4140 steel. Mater Des 32:3421–3430

Ambroziak A, Gul B (2007) Investigations of underwater FHPP for welding steel overlap joints. Arch Civ Mech Eng 7:67–76

Li S, Yang X, Cui L, Yin Y (2016) Influence of weld geometry and process parameters on the quality of underwater wet friction taper plug welding. Int J Adv Manuf Technol. doi:10.1007/s00170-016-8358-1

Yin Y, Yang X, Cui L, Cao J, Xu W (2015) Investigation on welding parameters and bonding characteristics of underwater wet friction taper plug welding for pipeline steel. Int J Adv Manuf Technol 81:851–861

Cui L, Yang X, Wang D, Cao J, Xu W (2014) Experimental study of friction taper plug welding for low alloy structure steel: welding process, defects, microstructures and mechanical properties. Mater Des 62:271–281

Yin Y, Yang X, Cui L, Wang F, Li S (2015) Material flow influence on the weld formation and mechanical performance in underwater friction taper plug welds for pipeline steel. Mater Des 88:990–998

Wang J, Lu S, Rong L, Li D (2015) Thermal cycling, microstructure and mechanical properties of 9Cr2WVTa steel welds. J Mater Process Technol 222:434–443

Sadeghian M, Shamanian M, Shafyei A (2014) Effect of heat input on microstructure and mechanical properties of dissimilar joints between super duplex stainless steel and high strength low alloy steel. Mater Des 60:678–684

Hattingh DG, Van Zyl C (2012) Temperature distribution for a friction taper stud weld in thick walled 10CrMo910 steel. RDJ S Afr Inst Mech Eng 28:37–45

Cui L, Yang X, Wang D, Hou X, Cao J, Xu W (2014) Friction taper plug welding for S355 steel in underwater wet conditions: welding performance, microstructures and mechanical properties. Mater Sci Eng A 611:15–28

Bhadeshia HKDH, Honeycombe RWK (2006) Steels: microstructure and properties. Butterworth-Heinemann, Oxford

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, F., Yang, X., Yin, Y. et al. Thermal process influence on microstructure and mechanical behavior for friction taper plug welding in structural steel S355. Int J Adv Manuf Technol 88, 3459–3466 (2017). https://doi.org/10.1007/s00170-016-9067-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9067-5