Abstract

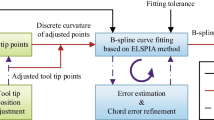

To improve the machining efficiency and cutting force stability for milling a pocket with an island, a lofting-based spiral tool path generation algorithm is presented. First, the machining area undergoes partition based on lofting lines through the profile vertices, and isogonal lofting lines are assigned according to the sub-area angular weight. Linear interpolation is proposed to get equal-spaced points between internal and external lofting points, and these interpolation points are circumferentially connected to form a spiral polyline. Next, control vertices that follow an exponential function distribution are inserted. Using these control vertices, a B-spline curve of any order can be defined. Finally, a spiral tool path for machining a pocket with an island is obtained. The algorithm can control the machining efficiency and machining precision by adjusting shape factor, lofting line number, and B-spline order according to specific processing requirements, and it can be directly applied to a machining center with a Non-uniform rational B-spline (NURBS) interpolation function. The experimental results show that, compared to contour-parallel, the C n continuous B-spline curve tool path has an obvious advantage on tool path length, machining efficiency, cutting force continuity, and workpiece surface quality.

Similar content being viewed by others

References

Han X, Tang L (2015) Precise prediction of forces in milling circular corners. Int J Mach Tools Manuf 88:184–193. doi:10.1016/j.ijmachtools.2014.09.004

Xiong ZH, Zhuang CG, Ding H (2011) Curvilinear tool path generation for pocket machining. P I Mech Eng B-J Eng 225(4):483–495. doi:10.1177/2041297510394085

Abrahamsen M (2014) Spiral toolpaths for high-speed machining of 2D pockets with or without islands. preprint arXiv: cs.CG/1412.5034

Lin Z, Fu J, He Y et al (2013) A robust 2D point-sequence curve offset algorithm with multiple islands for contour-parallel tool path. Comput Aided Design 45(3):657–670. doi:10.1016/j.cad.2012.09.002

Shih JL, Chuang SHF (2006) NURBS output based tool path generation for freeform pockets. Int J Adv Manuf Technol 29(7-8):714–721. doi:10.1007/s00170-005-2570-8

Kim H, Lee S, Yang M (2006) A new offset algorithm for closed 2D lines with Islands. Int J Adv Manuf Technol 29(11-12):1169–1177. doi:10.1007/s00170-005-0013-1

Midany TT, Elkeran A, Tawfik H (2009) A sweep-line algorithm and its application to spiral pocketing. Int J CAD/CAM 2(1):23–28

Held M, Spielberger C (2009) A smooth spiral tool path for high speed machining of 2D pockets. Comput Aided Design 41(7):539–550. doi:10.1016/j.cad.2009.04.002

Xu J, Sun Y, Zhang X (2013) A mapping-based spiral cutting strategy for pocket machining. Int J Adv Manuf Technol 67(9-12):2489–2500. doi:10.1007/s00170-012-4666-2

Banerjee A, Feng HY, Bordatchev EV (2012) Process planning for Floor machining of 2½D pockets based on a morphed spiral tool path pattern. Comput Ind Eng 63(4):971–979. doi:10.1016/j.cie.2012.06.008

Li XB, Liang JJ, Ni P et al (2014) Novel path generation algorithm for high-speed pocket milling. Int J Prod Res 52(2):397–404. doi:10.1080/00207543.2013.828172

Bhattacharjee B, Azeem A, Ali SM et al (2012) Development of a CNC interpolation scheme for CNC controller based on Runge-Kutta method. Int J Comput Aided Eng Technol 4(5):445–464. doi:10.1504/IJCAET.2012.048841

Rauch M, Duc E, Hascoet JY (2009) Improving trochoidal tool paths generation and implementation using process constraints modelling. Int J Mach Tools Manuf 49(5):375–383. doi:10.1016/j.ijmachtools.2008.12.006

Zhao H, Zhu L, Ding H (2013) A real-time look-ahead interpolation methodology with curvature-continuous B-spline transition scheme for CNC machining of short line segments. Int J Mach Tools Manuf 65:88–98. doi:10.1016/j.ijmachtools.2012.10.005

Lewis RM, Torczon V, Trosset MW (2000) Direct search methods: then and now. J Comput Appl Math 124(1):191–207. doi:10.1016/S0377-0427(00)00423-4

Romero-Carrillo P, Torres-Jimenez E, Dorado R et al (2015) Analytic construction and analysis of spiral pocketing via linear morphing. Comput Aided Des 69:1–10. doi:10.1016/j.cad.2015.07.008

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Z., Li, X., Song, Y. et al. Lofting-based spiral tool path generation algorithm for milling a pocket with an island. Int J Adv Manuf Technol 88, 2169–2178 (2017). https://doi.org/10.1007/s00170-016-8951-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8951-3