Abstract

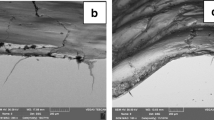

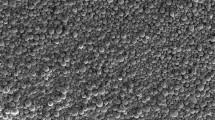

The purpose of this article is to investigate the microstructure and mechanical properties of surfacing layers (wear layer and transition layer) of a hot forging die manufactured by the bimetal-gradient-layer surfacing method, which is based on ZG29MnMoNi cast steel before and after forged 5761 parts on a 63MN hot die forging press. The finite element model of a die was established. Subsequently, a simulation was conducted to analyze the temperature field of the die and its cycle features under working conditions. Microstructure and mechanical property were measured. Results indicated that the microstructure of the wear layer mainly consists of temper sorbite, ferrite and carbides. The transition layer before and after service is mainly composed of both temper sobrite, lower bainite, and a small amount of temper martensite. The mechanical properties of wear and transition layers declined significantly after service. The tensile strength, yield strength, reduction of area, and elongation of wear layer declined by 41.6, 32.5, 28.3, and 24.5 %, respectively. With those indexes the transition layer decreased by 36.6, 34, 24.4, and 19.8 %, respectively. Microhardness and impact energy of wear and transition layers have showed a decrease of 17, 6 % and 51.2, 32.6 %, respectively. The impact fracture mode of both wear and transition layers is typically intergranular fracture after service. As a conclusion, it was determined that the service process sufficiently influenced the mechanical properties of the surfacing layers.

Similar content being viewed by others

References

Song Y, Yan Y, Zhang R, Lu Q, Xu D (2002) Boundary model between casting and mould and its influence on the dimensional accuracy analysis of precision castings [J]. Proc Inst Mech Eng B J Eng Manuf 246(8):1123–1134

Trethewey KR, Roberget DR (1995) Corrosion management in the twenty-first century [J]. Br Corros J 3:192–197

Devi MU (2002) Damage mechanisms in salt bath nitro-carburised and plasma nitrided hot forging dies of H11 tool steel [J]. ISIJ Int 42(5):527–533

Shah S, Narendra B (2002) Laser surface-engineered vanadium carbide coating for extended die life [J]. J Mater Process Technol 124(2):105–112

Davis JR (2003) Handbook of materials for medical devices [M]. ASM International, Ohio

Lu S (2014) The new method basis and application of the gorging die with bimetal gradient layer on cast steel [D]. Chongqing University

Wang HJ, Wu YZ, Wang HC, Sun YZ, Wang G (2011) Design method and verification for long life hot forging die [J]. Mater Res Innov 15:377–380

Goizet V, Bourouga B, Bardon JP (1999) Experimental study of the heat transfer at the workpiece-die interface during a hot forging operation [J]. Rev Metall Cah Inf Tech 96(5):601–608

Yoshida J, Katsumata M, Yamazaki Y (1998) Effect of primary carbide on fatigue life in die steel for cold working [J]. Tetsu Hagane J Iron Steel Inst Jpn 84(1):79–84

Brucelle O, Bernhart G (1999) Methodology for service life increase of hot forging tools [J]. J Mater Process Technol 81(1–3):237–246

Lu X, Zhou J, Zhang JS (2015) Optimization of welding thickness on casting-steel surface for production of forging die [J]. Int J Adv Manuf Technol 76:1411–1419

Zhang JS, Zhou J, Tao YP, Shen L, Li MY (2015) The microstructure and properties change of dies manufactured by bimetal-gradient-layer surfacing technology [J]. Int J Adv Manuf Technol 80(9–12):1807–1814

Albertin E, Sinatora A (2001) Effect of earbider faction and matrix microstructure On the Wear of eastiron balls tested in a laboratory ball mill [J]. Wear 2(50):492–501

Eghlimi A, Shamanian M, Eskandarian M, Zabolian A, Nezakat M, Szpunar JA (2015) Evaluation of microstructure and texture across the welded interface of super duplex stainless steel and high strength low alloy steel [J]. Surf Coat Technol 264:150–162

Lundin CD, Khan KK, Yang D (1995) Effect of carbon migration in Cr-Mo weldments on metallurgical structure and mechanical properties. Report No.1 [J]. Bull Weld Res Counc 407:1–49

Lippold C, Kotecki J (2005) Welding metallurgy and weldability of stainless steels [M]. John Wiley and Sons, p. 63–70

Steyn WJ, Briedenhann R (2012) Evaluation of microclimate effects on surfacing seal performance [J]. J Perform Constr Facil 26(2):138–144

Köse C, Kaçar R (2014) The effect of preheat & post weld heat treatment on the laser weldability of AISI 420 martensitic stainless steel [J]. Mater Des 64:221–226

Carrouge D, Bhadeshia HKDH, Woollin P (2004) Effect of d-ferrite on impact properties of super martensitic stainless steel heat affected zones [J]. Sci Technol Weld Join 9:377–389

HUANG ML, WANG L (1998) Carbon migration in 5Cr-0.5Mo/21Cr-12Ni dissimilar metal welds [J]. Metall Mater Trans A 29(12):3037–3046

Baghjari SH, Mousavi Akbari SAA (2013) Effects of pulsed Nd: YAG laser welding parameters and subsequent post-weld heat treatment on microstructure and hardness of AISI 420 stainless steel [J]. Mater Des 43:1–9

Takahashi M, Yasuda HY (2013) Variant selection of martensites in steel welded joints with low transformation temperature weld metals [J]. J Alloys Compd 577(1):601–604

Kurt B, Orhan N, Somunkıran I, Kaya M (2009) The effect of austenitic interface layer on microstructure of AISI 420 martensitic stainless steel joined by keyhole PTA welding process [J]. Mater Des 30(3):661–664

Zhao J, Zhao T, Hou CS, Zhang FC, Wang TS (2015) Improving impact toughness of high-C-Cr bearing steel by Si-Mo alloying and low-temperature austempering [J]. Mater Des 86:215–220

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, F., Zhou, J., Zhou, J. et al. Microstructure and properties of surfacing layers of dies manufactured by bimetal-gradient-layer surfacing technology before and after service. Int J Adv Manuf Technol 88, 1289–1297 (2017). https://doi.org/10.1007/s00170-016-8679-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8679-0