Abstract

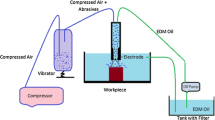

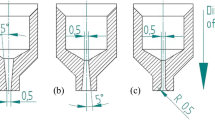

The purpose behind this work was the development of a hybrid methodology, which combines the electrical fischarge machining (EDM) with a high-pressure jet of dielectric fluid mixed with abrasive powder. The low MRR (material removal rate) observed on the EDM is, undoubtedly, one of the most important limitations of this process, especially today, where competitiveness among the enormous varieties of machining processes has attained an unbelievable level of speed and surface finishing. A special device was built in order to provide and apply the high-pressure abrasive jet. Cooper tube-shaped tools were used for the experiments and the machined material consisted of commercial high-speed steel (AISI M2). Kerosene, deionized water, and mineral-based oil were used as dielectric fluids and the abrasive was constituted of SiC (600 mesh), with jet pressures varying from zero to 100 bar, and abrasive concentration kept fixed at 30 g/l. The results show an eightfold increase in MRR when the EDM process is aided by abrasive particles. Furthermore, remarkable gains were obtained with kerosene and deionized water, both with enhanced surface finishing. Therefore, this new process, denominated as abrasive jet electrical discharge machining (AJEDM), proves to be efficient for increasing machining velocity while decreasing the surface roughness and its use has shown itself to be technically viable.

Similar content being viewed by others

References

Rajurkar KP, Zhu D, Mcgeough JA, Kozak J, De Silva A (1999) New developments in electro-chemical machining. CIRP Ann 48(2):569–579

Pajak PT, Silva AKM, Harrison DK, Mcgeough JA (2004) Modeling the aspects of precision and efficiency in laser-assisted jet electrochemical machining (LAJECM). J Mater Process Technol 149:512–518

Kozak J, Rajurkar KP (2001) Hybrid machining process evaluation and development. University or Nebraska, Lincoln

Mcgeough JA (1989) Advanced methods of machining. Chapman and Hall, London

Raslan AA, Arantes LJ (2009) Método de Usinagem Híbrida Combinando Descargas Elétricas e Erosão Abrasiva. Brasil, Patente PI0703468-7A2, 26p

Amorim FL (2002) Tecnologia de Eletroerosão por Penetração da Liga de Alumínio AMP 8000 e da Liga de Cobre CuBe para Ferramentas de Moldagem de Materiais Plásticos. Tese de Doutorado - Universidade Federal de Santa Catarina, Florianópolis-SC, 134 p

Wong YS, Lim LC, Lee LC (1995) Effects of flushing on electro-discharge machining surfaces. J Mater Process Technol 48:299–305

Ming YQ, He LY (1995) Powder-suspension dielectric fluid for EDM. J Mater Process Technol 52:44–54

Fernandes AL (1999) Efeito da Adição de Pó de Carboneto de Silício nos Fluidos Dielétricos Sobre o Desempenho da Usinagem por Descargas Elétricas do Aço-Rápido AISI M2. Dissertação de Mestrado - Universidade Federal de Uberlândia, Uberlândia-MG, 72 p

Arantes LJ (2001) Avaliação de Fluidos Dielétricos no Processo de Usinagem por Descargas Elétricas. Dissertação de Mestrado, Universidade Federal de Uberlândia, Uberlândia-MG, 74 p

Yih-Fong T, Fu-Ghen C (2005) Investigation into some surface characteristics of electrical discharge machined SKD-11 using powder-suspension dielectric Oil. J Mater Process Technol 170:385–391

Zhao WS, Meng QG, Wang ZL (2002) The application of research on powder mixed EDM in rough machining. J Mater Process Technol 129:30–33

Lin YC, Chen YF, Wang AC, Sei WL (2012) Machining performance on hybrid process of abrasive jet machining and electrical discharge machining. Trans Nonferrous Metals Soc China 2(supplement 3):775–780

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arantes, L.J., da Silva, E.R., dos Santos, R.F. et al. The electrical discharge machining process aided by abrasive jet. Int J Adv Manuf Technol 87, 411–420 (2016). https://doi.org/10.1007/s00170-016-8517-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8517-4