Abstract

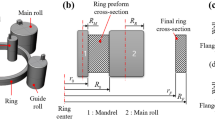

Cold profiled ring rolling (CPRR) is an advanced local incremental forming process with complexity and high nonlinearity. In this process, the feed rate of mandrel is a key factor affecting the expanding speed of ring outer radius and the filling behavior; thus, it is very significant to rationally design the feed rate for precise controlling the deformation process. Aimed at the CPRR process, the problem of feed rate planning under two variable feed patterns, which are constant expanding speed of ring outer radius (P CES) and constant feed amount per ring revolution (P CFA), has been solved successfully by using the hypothesis-testing approach in this paper. First, according to the relation between the ring outer radius R and the ring reduction ΔH, a novel mathematical solution for planning the feed rates under P CES and P CFA has been proposed, in which a series of points of (R, ΔH) under constant feed rate (P CFR) pattern have been taken into consideration. Second, two differential equations obtaining variable feed rate curves under P CES and P CFA have been built and their solving processes have also been given, and subsequently a new quantitative planning flow of variable feed rates has been presented. Third, an example of three feed rates planning under P CFR, P CES, and P CFA for a practical closed cold T-shaped ring rolling process in the design phase has been realized, and their validity has been proven by three-dimensional finite element numerical simulation. The achievements can provide a guideline for planning the feed rates of the relevant complex profiled ring rolling processes to improve efficiency and reduce cost.

Similar content being viewed by others

References

Li LY, Yang H, Guo LG (2014) Hot shape rolling. Compre Mater Process 5(19):393–439

Hua L, Qian DS (2014) Ring rolling forming theory and technology for bearing. J Mech Eng 50(16):70–76

Utsunomliya H, Saito Y, Shinlda T (2002) Elastic-plastic finite element analysis of cold ring rolling process. J Mater Process Technol 125–126:613–618

Li LY, Yang H, Guo LG, Sun ZC (2008) A control method of guide rolls in 3D-FE simulation of ring rolling. J Mater Process Technol 205(1-3):99–110

Qian DS (2014) Research on mechanical principle and technology theory of profile cold ring rolling. Wuhan University of Technology Press, Wuhan (in Chinese)

Li LY, Li X, Liu J, He Z (2015) Multi-response optimisation design of parameters for cold ring rolling process using fuzzy-grey method. Int J Mater Prod Technol 50(2):101–123

Hua L, Qian QS, Pan LB (2009) Deformation behaviours and conditions in L-section profile cold ring rolling. J Mater Process Technol 209(11):5087–5096

Hua L, Qian DS, Pan LB (2009) Research on plastic deformation behaviour and conditions for stepped hole ring rolling. Mater Sci Technol 25(11):1397–1407

Qian DS, Hua L (2010) Blank design optimization for stepped-section profile ring rolling. Sci China Technol Sci 53(6):1612–1619

Yang H, Li LY, Wang M, Guo LG (2010) Research on the expanding deformation of ring radius in cold profiled ring rolling process. Sci China Technol Sci 53(3):813–821

Hua L, Zuo ZJ, Lan J, Qian DS (2007) Research on following motion rule of guide roll in cold rolling groove ball ring. J Mater Process Technol 187–188:743–746

Qian DS, Hua L, Pan LB (2009) Research on gripping conditions in profile ring rolling of raceway groove. J Mater Process Technol 209(6):2794–2802

Zhao YM, Qian DS (2010) Effect of rolling ratio on groove-section profile ring rolling. J Mech Sci Technol 24(8):1679–1687

Hua L, Qian DS, Pan LB (2008) Analysis of plastic penetration in process of groove ball-section ring rolling. J Mech Sci Technol 22(9):1374–1382

Li LY, Li X, Liu J, He Z (2013) Modelling and simulation of cold rolling process for double groove ball-section ring. Int J Adv Manuf Technol 69(5-8):1717–1729

Li LY, Li X, Liu J, He Z (2015) Effects of speed parameters on cold rolling process of double groove ball-section ring. Mater Res Innov 19(S5):1323–1327

Tian L, Luo Y, Mao HJ, Hua L (2013) A hybrid of theory and numerical simulation research for virtual rolling of double-groove ball rings. Int J Adv Manuf Technol 69(1-4):1–13

Qian DS, Hua L, Pan LB (2009) Blank design optimization for T-section ring rolling. Ironmak Steelmak 36(6):462–469

Li LY, Yang H, Guo LG, Sun ZC (2007) Research on interactive influences of parameters on T-shaped cold ring rolling process by 3D-FE numerical simulation. J Mech Sci Technol 21(10):1541–1547

Li LY, Yang H, Guo LG, Sun ZC (2010) Research on the influence of material properties and forming parameters in T-shaped closed cold ring rolling process. Int J Mater Prod Technol 38(2-3):323–336

Li LY, Li X, He Z (2011) Research on the effect of geometric parameters of ring blank on cold profiled ring rolling process. Int J Mater Prod Technol 42(3-4):195–208

Li LY, Li X, He Z (2012) 3D-FE simulation of inhomogeneous stress and strain distributions in cold profiled ring rolling process under different hardening coefficients. Int J Mater Prod Technol 43(1-4):205–225

Li LY, Li X, Liu J, He Z (2015) Effects of rolls sizes on uniformity of strain and variation of configuration in cold closed T-shaped rolling process of HE30 aluminum alloy ring. Int J Adv Manuf Technol. doi:10.1007/s00170-015-8164-1

Allwood JM, Tekkaya AE, Stanistreet TF (2005) The development of ring rolling technology. Steel Res Int 76(2-3):111–120

Ryttberg K, Knutson WM, Recina V, Dahlman P, Nyborg L (2010) The effect of cold ring rolling on the evolution of microstructure and texture in 100Cr6 steel. Mater Sci Eng A 527(9):2431–2436

Hawkyard JB, Johnson W, Kirkland J, Appleton E (1973) Analyses for roll force and torque in ring rolling with some supporting experiments. Int J Mech Sci 15(11):873–893

Mamalis AG, Hawkyard JB, Johnson W (1976) Spread and flow patterns in ring rolling. Int J Mech Sci 18(1):11–16

Ryoo J, Yang DY, Johnson W (1986) The influence of process parameters on torque and load in ring rolling. J Mech Work Technol 12(3):307–321

Boucly P, Oudin J, Ravalard Y (1988) Simulation of ring rolling with new wax-based model materials on a flexible experimental machine. J Mech Work Technol 16(2):119–143

Kluge A, Lee YH, Wiegels H, Kopp R (1994) Control of strain and temperature distribution in the ring rolling process. J Mater Process Technol 45(1):137–141

Hua L, Zhao ZZ (1997) The extremum parameters in ring rolling. J Mater Process Technol 69(1):273–276

Sun ZC, Yang H, Ou XZ (2008) Thermo-mechanical coupled analysis of hot ring rolling process. Trans Nonferrous Metals Soc China 18(5):1216–1222

Sun ZC, Yang H, Ou XZ (2010) Effects of process parameters on microstructural evolution during hot ring rolling of AISI 5140 steel. Comput Mater Sci 49(1):134–142

Zhou J, Wang FL, Wang MH, Xu WJ (2011) Study on forming defects in the rolling process of large aluminum alloy ring via adaptive controlled simulation. Int J Adv Manuf Technol 55(1-4):95–106

Anjami N, Basti A (2011) Investigation on constant and variable feed speeds effects in ring rolling process using 3D FEM. Adv Mater Res 264–265:1776–1781

Wang C, Van DBT, Omerspahic E, Recina V, Geijselaers B (2014) Influence of feed rate on damage development in hot ring rolling. Proc Eng 81(1):292–297

Wang C, Geijselaers HJM, Omerspahic E, Recina V, van den Boogaard AH (2016) Influence of ring growth rate on damage development in hot ring rolling. J Mater Process Technol 227:268–280

Hua L, Zuo ZJ, Lan J et al (2006) Control method design for feed rate of idle roller in cold ring rolling. China Mech Eng 17(9):953–957 (In Chinese)

Yan FL, Hua L, Wu YQ (2007) Planning feed speed in cold ring rolling. Int J Mach Tools Manuf 47(11):1695–1701

Xu WJ, Yang XB, Jiang ZY, Wang QL (2014) Feeding strategy design for steel 42CrMo in radial-axial ring rolling using processing map. Int J Mater Form 7(4):405–412

Xu WJ, Zhou X, Long J, Wang QL, Yang XB (2015) Feeding interval design considering multiconstraints in flat ring rolling process. Int J Adv Manuf Technol 81(1-4):219–229

Zhu S, Yang H, Guo LG, Hu LL, Chen XQ (2014) Research on the effects of coordinate deformation on radial-axial ring rolling process by FE simulation based on in-process control. Int J Adv Manuf Technol 72(1):57–68

Zhou PZ, Zhang LW, Gu SD, Ruan JH, Teng LH (2014) Mathematic modeling and FE simulation of radial-axial ring rolling large L-section ring by shape axial roll. Int J Adv Manuf Technol 72(5):729–738

Mohammad S, Mahdi H (2015) A new approach in modeling of guide and conical rolls in the ring rolling process. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7212-1

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, L., Li, X., Liu, J. et al. A quantitative planning method of variable feed rates for cold profiled ring rolling process. Int J Adv Manuf Technol 86, 2585–2593 (2016). https://doi.org/10.1007/s00170-016-8354-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8354-5