Abstract

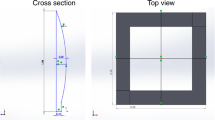

In general practice, chip breakers are used to break chips in turning operations for chip disposal. However, chips of highly ductile materials such as low carbon steel or thin chips generated in finishing operations may not be broken easily with conventional chip breakers. They cause chip-jam and significant downtime in actual production. This paper proposes a novel approach where the generated chip is not broken but guided to overcome first the chip-jam and next to improve the efficiency of conventional turning operations by realizing the chip-pulling turning process. A novel cutting tool geometry is developed to suppress the chip’s side curl to generate straight continuous chip flowing away from the cutting point and hence suppress the chip-jam. The proposed tool tip geometry contains “guide grooves” engraved onto the rake face. The groove topography is optimized to control the chip flow robustly at various cutting conditions so that the cut chip can be guided for effective chip guidance. Continuously flowing guided chip is then pulled to reduce the friction force on the rake face to enhance the machinability. Experimental results show that the designed cutting tool geometry robustly controls the chip flow, and the chip-pulling turning process shows significant potential towards achieving higher machinability in hard turning.

Similar content being viewed by others

References

Hong SY, Yucheng D, Ekkens RG (1999) Improving low carbon steel chip breakability by cryogenic chip cooling. Int J Mach Tools Manuf 39(7):1065–1085

Nakayama K (1960) Modes of chip-breaking by chip-breaker. J JSPE 26/8

Nakayama K (1972) Origins of side curl of chip in metal cutting. Bull JSPE 6(3):99–101

Shi T, Ramaligam S (1991) Slip-line solution for orthogonal cutting with a chip-breaker and flank wear. Int J Mech Sci 33(3):689–704

Kharkevich A, Venuvinod PK (1999) Basic geometric analysis of 3-D chip forms in metal cutting: part 1: determining up-curl and side-curl radii. Int J Mach Tools Manuf 39(5):751–760

Kaldor SS, Ber AA, Lenz EE (1979) On the mechanism of chip breaking. ASME J Manuf Sci Eng 101(3):241–249

Christian N, Wolfgang H, van Luttervelt CA (1989) Characteristic parameters of chip control in turning operations with indexable inserts and three-dimensionally shaped chip formers. CIRP Annals Manuf Technol 38(1):75–79

Choi JP, Lee SJ (2001) Efficient chip breaker design by predicting the chip breaking performance. Int J Adv Manuf Technol 17(7):489–497

Jawahir IS, Oxley PLB (1988) The tool restricted contact effect as a major influencing factor in chip breaking: an experimental analysis. CIRP Annals Manuf Technol 37(1):121–126

Jawahir IS (1990) On the controllability of chip breaking cycles and modes of chip breaking in metal machining. CIRP Annals Manuf Technol 39(1):47–51

Kharkevich AG, Venuvinod PK (2002) Extension of basic geometric analysis of 3-D chip forms in metal cutting to chips with obstacle-induced deformation. Int J Mach Tools Manuf 42(20):201–213

Balaji AK, Ghosh R, Fang XD, Stevenson R, Jawahir IS (2006) Performance-based predictive models and optimization methods for turning operations and applications: part 2—assessment of chip forms/chip breakability. J Manuf Process 8(2):144–153

Buchkremer S, Klocke F, Veselovac D (2015) 3D FEM simulation of chip breakage in metal cutting. Int J Adv Manuf Technol:1–17. DOI: 10.1007/s00170-015-7383-9

Buchkremer S, Wu B, Lung D, Münstermann S, Klocke F, Bleck W (2014) FE-simulation of machining processes with a new material model”. J Mater Process Technol 214(3):599–611

Fang XD, Jawahir IS (1992) An expert system based on fuzzy mathematical model for chip breakability assessments in automated machining, vol. IV. Proc. 2nd ASME Conf, Atlanta

Zhang XD, Lee LC, Seah KHW (1995) Knowledge base for chip management system. J Mater Process Technol 48(1–4):215–221

Kawasegi N, Sugimori H, Morimoto H, Morita N, Hori I (2009) Development of cutting tools with microscale and nanoscale textures to improve friction behavior. Precis Eng J Int Soc Precis Eng Nanotechnol 33:248–254

Sugihara T, Enomoto T (2012) Improving anti-adhesion in aluminum alloy cutting by micro stripe texture. Precis Eng J Int Soc Precis Eng Nanotechnol 36(2):229–237

Enomoto T, Sugihara T, Yukinaga S, Hirose K, Satake U (2012) Highly wear-resistant cutting tools with textured surfaces in steel cutting. CIRP Annals Manuf Technol 61(1):571–574

Chang W, Sun J, Luo X, Ritchie J M, Mack C (2011) Investigation of microstructured milling tool for deferring tool wear. Wear 271(9-10):2433–2437

Kiyota H, Itoigawa F, Nakamura T (2014) Experimental research of micro-textured tool for reduction in cutting force. 17th Conference of the European Scientific Association on Material Forming, ESAFORM 2014, Espoo-Finland

Shamoto E, Aoki T, Sencer B, Suzuki N, Hino R, Koide T (2011) Control of chip flow with guide grooves for continuous chip disposal and chip-pulling turning. CIRP Annals Manuf Technol 60(1):125–128

Sencer B, Tomoya A, Shamoto E, Hasegawa T, Koide T (2014) Development of a chip pulling system for efficient turning. Procedia CIRP 14:616–620

Colwell LV (1954) Predicting the angle of chip flow for single point cutting tools. Trans ASME 76:199–204

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aoki, T., Sencer, B., Shamoto, E. et al. Development of a high-performance chip-guiding turning process—tool design and chip flow control. Int J Adv Manuf Technol 85, 791–805 (2016). https://doi.org/10.1007/s00170-015-7990-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7990-5