Abstract

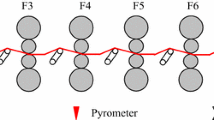

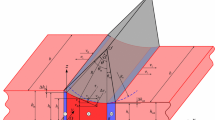

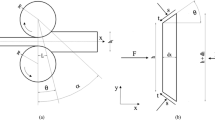

In hot strip rolling process, rolling schedule setup, geometrical accuracy (thickness and profile), and even the final product homogeneity of mechanical properties are affected by the automatic control, and the rolling force and torque are the prerequisite in the control process. A new cosine velocity field is firstly proposed in this paper to get the values of the required minimum rolling force and torque. The field and equal area (EA) yield criterion are used to integrate the internal plastic deformation power. Using the co-line vector inner product method, the friction power is analyzed. Finally, the analytical expressions of rolling force, rolling torque, and stress effective factor are obtained. The theoretical predictions of rolling forces are compared with on-line measured ones in a hot strip rolling plant and other researchers’ models. Results show that the calculated rolling forces are in fair agreement with the actual measured ones, and the proposed solution is considered to be applicable for solving hot strip finish rolling.

Similar content being viewed by others

References

Hill R (1963) A general method of analysis for metal-working processes. J Mech Phys Solids 11(5):305–326

Oh SI, Kobayashi S (1975) An approximate method for a three-dimensional analysis of rolling. Int J Mech Sci 17(4):293–305

Martins PAF, Marques MJMB (1999) Upper bound analysis of plane strain rolling using a flow function and the weighted residuals method. Int J Numer Meth Eng 44(11):1671–1683. doi:10.1002/(Sici)1097-0207(19990420)44:11<1671::Aid-Nme559>3.0.Co;2-2

Sezek S, Aksakal B, Can Y (2008) Analysis of cold and hot plate rolling using dual stream functions. Mater Design 29(3):584–596. doi:10.1016/j.matdes.2007.03.005

Kobayashi S, Oh SI, Altan T (1989) Metal forming and the finite-element method. Oxford university press, New York

Mori K, Osakada K (1990) Finite element simulation of three‐dimensional deformation in shape rolling. Int J Numer Meth Eng 30(8):1431–1440

Kwak WJ, Kim YH, Park HD, Lee JH, Hwang SM (2000) FE-based on-line model for the prediction of roll force and roll power in hot strip rolling. ISIJ Int 40(10):1013–1018. doi:10.2355/isijinternational.40.1013

Mori K, Otomo Y, Yoshimura H (2006) Parallel processing of 3D rigid-plastic finite element method using diagonal matrix. J Mater Process Technol 177(1–3):63–67. doi:10.1016/j.jmatprotec.2006.04.064

Zhang JL, Cui ZS (2011) Continuous FEM simulation of multi-pass plate hot rolling suitable for plate shape analysis. J Cent South Univ T 18(1):16–22. doi:10.1007/s11771-011-0652-3

Narayanasmy R, Ponalagusamy R, Venkatesan R, Srinivasan P (2006) An upper bound solution to extrusion of circular billet to circular shape through cosine dies. Mater Design 27(5):411–415. doi:10.1016/j.matdes.2004.11.026

Chandra S, Dixit US (2004) A rigid-plastic finite element analysis of temper rolling process. J Mater Process Technol 152(1):9–16. doi:10.1016/j.jmatprotec.2003.11.003

Tabatabaei SA, Abrinia K, Givi MKB (2014) Application of equi-potential lines method for accurate definition of the deforming zone in the upper-bound analysis of forward extrusion problems. Int J Adv Manuf Tech 72(5–8):1039–1050. doi:10.1007/s00170-014-5647-4

Zhao DW, Fang Q, Li CM, Liu XH, Wang GD (2010) Derivation of plastic specific work rate for equal area yield criterion and its application to rolling. J Iron Steel Res Int 17(4):34–38

Lan LY, Li CM, Zhao DW, Qiu CL (2012) Derivation of equal area criterion and its application to crack tip plastic zone analysis. Appl Mech Mat 110:2918–2925

Liu YM, Zhang DH, Zhao DW, Sun J (2015) Analysis of vertical rolling using double parabolic model and stream function velocity field. Int J Adv Manuf Tech. doi:10.1007/s00170-015-7393-7

Abrinia K, Mirnia MJ (2009) A new generalized upper-bound solution for the ECAE process. Int J Adv Manuf Tech 46(1–4):411–421. doi:10.1007/s00170-009-2103-y

Hua L, Deng JD, Qian DS, Ma Q (2014) Using upper bound solution to analyze force parameters of three-roll cross rolling of rings with small hole and deep groove. Int J Adv Manuf Tech 76(1–4):353–366. doi:10.1007/s00170-014-6107-x

Zhang SH, Zhao DW, Gao CR (2012) The calculation of roll torque and roll separating force for broadside rolling by stream function method. Int J Mech Sci 57(1):74–78. doi:10.1016/j.ijmecsci.2012.02.006

Sun YK (2010) Model and control of cold and hot rolling mill for sheets and strips. Metallurgical Industry Press, Beijing

Sims RB (1954) The calculation of roll force and torque in hot rolling mills. Proc I Mech Eng 168(1954):191–200. doi:10.1243/pime_proc_1954_168_023_02

Gupta S, Ford H (1967) Calculation method for hot rolling of steel sheet and strip. J Iron Steel Institute 205(2):186–190

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, DH., Liu, YM., Sun, J. et al. A novel analytical approach to predict rolling force in hot strip finish rolling based on cosine velocity field and equal area criterion. Int J Adv Manuf Technol 84, 843–850 (2016). https://doi.org/10.1007/s00170-015-7692-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7692-z