Abstract

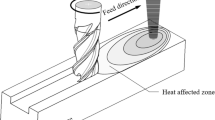

The purpose of this work was to study laser-assisted machining (LAM) according to the tool path inclination angle of a titanium alloy workpiece. Previous studies have investigated using LAM for the linear machining of difficult-to-cut materials. However, during the linear machining of an inclined planar workpiece, the laser spot is deformed into an elliptical shape, and then, the tool follows the long major axis of the elliptical laser spot. For tool path inclination angle machining, the tool follows the arbitrarily oriented direction of the elliptical laser spot. Thus, determining the preheating temperature of the workpiece by tool path inclination angle processing is different from that of linear processing. In this work, a study was carried out to optimize the preheating and machining based on the tool path inclination angle. The optimal laser power according to tool path inclination angle was determined through thermal analysis, and the thermal analysis results were compared with the results from preheating experiments. Also, machining experiments were conducted using the as-determined laser power.

Similar content being viewed by others

References

Lee JH, Shin DS, Suh J, Cho HY, Kim KW (2008) Trends of laser integrated machine. J Korean Soc Precis Eng 25:20–26

Pei ZJ, Khanna N, Ferreira PM (1995) Rotary ultrasonic machining of structural ceramics—a review. Ceram Eng Sci Proc 16:259–278

Chang CW, Kuo CP (2007) An investigation of laser-assisted machining of Al2O3 ceramics planning. Int J Mach Tools Manuf 47:452–461

Research report of the National Research Foundation of Korea (NRF) (2014) A new conceptual 3-dimensional laser assisted machining system 2013035186

Melkote S, Kumar M, Hashimoto F, Lahoti G (2009) Laser assisted micro-milling of hard-to-machine materials. J CIRP 58:45–48

Ding H, Shin YC (2010) Laser-assisted machining of hardened steel parts with surface integrity analysis. Int J Mach Tools Manuf 50:106–114

Brecher C, Emonts M, Rosen CJ, Hermani JP (2011) Laser-assisted milling of advanced materials. Phys Procedia 12:599–606

Zhang X, Liu CR, Yao Z (2007) Experimental study and evaluation methodology on hard surface integrity. Int J Adv Manuf Technol 34:141–148

Chang CW, Kuo CP (2007) An investigation of laser-assisted machining of Al2O3 ceramics planning. Int J Mach Tools Manuf 47:452–461

Kim KS, Lee CM (2011) Analysis of moving heat source for laser assisted machining of plate by feed rate control. J Korean Soc Precis Eng 28:1341–1346

Lee SJ, Kim JD, Suh J (2014) Microstructural variations machining characteristics of silicon nitride ceramics from increasing the temperature in laser assisted machining. Int J Precis Eng Manuf 15:1269–1274

Pfefferkorn FE, Incropera FP, Shin YC (2005) Heat transfer model of semi-transparent ceramics undergoing laser-assisted machining. Int J Heat Mass Transf 48:1999–2012

Ding H, Shen N, Shin YC (2012) Thermal and mechanical modeling analysis of laser-assisted micro-milling of difficult-to-machine alloys. J Mater Process Technol 212:601–613

Kalyon M, Yilbas BS (2003) Laser pulse heating: a formulation of desired temperature at the surface. Opt Lasers Eng 39:109–119

Yang B, Shen X, Lei S (2009) Mechanisms of edge chipping in laser-assisted milling of silicon. Int J Mach Tools Manuf 49:344–350

Kim JH, Choi JY, Lee CM (2014) A study on the effect of laser preheating on laser assisted turn-mill for machining square and spline members. Int J Precis Eng Manuf 15:275–282

Kim TW, Lee CM (2015) Determination of the machining parameters of nickel-based alloys by high-power diode laser. Int J Precis Eng Manuf 16:309–314

Rozzi JC, Pfefferkorn FE, Shin YC (2000) Experimental evaluation of the laser assisted machining of silicon nitride ceramics. J Manuf Sci Eng 122:666–670

Kim DH, Lee CM (2014) A study of cutting force and preheating-temperature prediction for laser-assisted milling of Inconel 718 and AISI 1045 steel. Int J Heat Mass Transf 71:264–274

Kang DW, Lee CM (2014) A study on the development of the laser-assisted milling process and a related constitutive equation for silicon nitride. CIRP Ann Manuf Technol 63:109–112

Kang DW, Lee CM (2013) A study on determining the exponents for a constitutive equation in laser assisted machining. Int J Precis Eng Manuf 14:2051–2054

Lei S, Shin YC, Incropera FP (2000) Deformation mechanisms and constitutive modeling for silicon nitride undergoing laser-assisted machining. Int J Mach Tools Manuf 40:2213–2233

Sim MS (2015) A study on laser assisted machining according to tool path Inclination angle of inclined workpiece and workpiece with rotated angle with respect to 2-axis. Dissertation of Changwon National University, Republic of Korea M. S

Kim KS, Lee CM (2012) Prediction of preheating conditions for the inclined laser assisted machining. J Cent South Univ 19:3079–3083

Kim DH and Lee CM (2013) A fundamental study on the absorptivity of diode laser for titanium alloy. Proc. of the KSMTE Spring conference 235

Yang J, Sun S, Brandt M, Yan W (2010) Experimental investigation and 3D finite element prediction of the heat affected zone during laser assisted machining of Ti6Al4V alloy. J Mater Process Technol 210:2215–2222

Neugebauer R, Denkena B, Wegener K (2007) Mechatronic systems for machine tools. CIRP Ann Manuf Technol 56:657–686

Brecher C, Rosen CJ, Emonts M (2010) Laser-assisted milling of advanced materials. Phys Procedia 5:259–272

Kim TW, Lee CM (2015) A study on the development of milling process for silicon nitride using ball end-mill tools by laser-assisted machining. Int J Adv Manuf Technol 77:1205–1211

Sim MS, Lee CM (2014) A study on the laser preheating effect of Inconel 718 specimen with rotated angle with respect to 2-axis. Int J Precis Eng Manuf 15:189–192

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sim, M.S., Lee, C.M. Determination of optimal laser power according to the tool path inclination angle of a titanium alloy workpiece in laser-assisted machining. Int J Adv Manuf Technol 83, 1717–1724 (2016). https://doi.org/10.1007/s00170-015-7684-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7684-z