Abstract

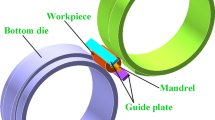

The trend towards lightweight construction has increased the use of hollow shafts. Cross wedge rolling (CWR) is a competitive near-net-shape forming process that can reduce costs and improve quality in the production of hollow shafts. The ovality of workpiece is the most important issue for making hollow shafts by cross wedge rolling with mandrel, and the process parameters are the main influence factors. The relationships between the process parameters and ovality were investigated by analyzing the influence of the helical and circular contact area between the tool and workpiece on the metal flow using the finite element method. Through the definition of ovality coefficient, a method for predicting the ovality of workpiece and choosing the process parameters was established. The simulation results were verified via rolling experiments and used to develop a process of cross wedge rolling the axle sleeves of truck with good forming quality. This work can provide a theoretical guidance for the tools design and production application of cross wedge rolling hollow shafts with mandrel.

Similar content being viewed by others

References

Hu ZH, Zhang KS, Wang BY, Shu XD, Yang CP (2004) Forming technology and simulation of cross wedge rolling parts. Metall. Ind Press, Beijing

Dong YM, Tagavi K, Lovell M, Deng Z (2000) Analysis of stress in cross wedge rolling with application to failure. Int J Mech Sci 42:1233–1253

Li Q, Lovell M (2004) The establishment of a failure criterion in cross wedge rolling. Int J Adv Manuf Technol 24:180–189

Li Q, Lovell M (2008) Cross wedge rolling failure mechanisms and industrial application. Int J Adv Manuf Technol 37:265–278

Wang MT, Li XT, Du FS, Zheng YZ (2005) A coupled thermal-mechanical and microstructural simulation of the cross wedge rolling process and experimental verification. Mater Sci Eng A 391:305–312

Wang MH, Xiang D, Xiao C, Zhou J, Jia Z (2012) Influence of cooling condition of tools on central deformation of workpiece and tool wear in cross wedge rolling. Int J Adv Manuf Technol 59:473–482

Jia Z, Zhou J, Ji JJ, Zhen ZZ, Xiang LD, Sun XT (2013) Influence analysis of area reduction for necking in twice-stage. Int J Adv Manuf Technol 66:1407–1413

Neugebauer R, Kolbe M, Glass R (2001) New warm forming processes to produce hollow shafts. J Mater Process Technol 119:277–282

Neugebauer R, Glass R, Kolbe M, Hoffmann M (2002) Optimisation of processing routes for cross rolling and spin extrusion. J Mater Process Technol 125–126:856–862

Zhang KS, Wang BY, Liu JP, Hu ZH (2001) Analysis on stable rolling condition of hollow workpiece rolled by cross wedge rolling. J Univ Sci Technol Beijing 23(2):155–157

Bartnicki J, Pater Z (2004) The aspects of stability in cross-wedge rolling processes of hollowed shafts. J Mater Process Technol 155–156:1867–1873

Bartnicki J, Pater Z (2005) Numerical simulation of three-rolls cross-wedge rolling of hollowed shaft. J Mater Process Technol 164–165:1154–1159

Urankar S, Lovell M, Morrow C, Li Q, Kawada K (2006) Establishment of failure conditions for the cross-wedge rolling of hollow shafts. J Mater Process Technol 177:545–549

Urankar S, Lovell M, Morrow C, Li Q, Kawada K (2006) Development of a critical friction model for cross wedge rolling hollow shafts. J Mater Process Technol 177:539–544

Ding W, Yang CP, Zhang KS, Hu ZH (2010) Thermomechanical coupled numerical simulation on cross wedge rolling of hollow shaft parts with equal inner diameter. J Univ Sci Technol Beijing 32(4):525–529

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, C., Hu, Z. Research on the ovality of hollow shafts in cross wedge rolling with mandrel. Int J Adv Manuf Technol 83, 67–76 (2016). https://doi.org/10.1007/s00170-015-7478-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7478-3