Abstract

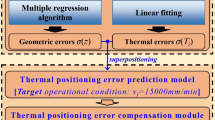

Thermally induced errors and load-induced errors are two key factors affecting the accuracy of machine tools. This paper proposes a strategy to build an error map of a machine tool by considering both thermal and load effects. A moderation model is developed to analyze the positioning errors with thermal effects, and a Fourier series model is used to fit the straightness errors. Based on actual cutting tests, relationships between cutting forces and motor currents are established. A load test is conducted in which a pushing cylinder is used to simulate actual cutting forces. The changes in error motions under different loads are obtained. An experimental verification is conducted on an NC lathe, whose error map is generated by integrating thermal and load effects. As actual cutting results show, when thermal and load effects are simultaneously compensated, the machining accuracy increases by 10 % as compared with when only thermal effects are compensated.

Similar content being viewed by others

References

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools—a review part I: geometric, cutting-force induced and fixture-dependent errors. Int J Mach Tools Manuf 40(9):1235–1256

Yang H, Ni J (2003) Dynamic modeling for machine tool thermal error compensation. J Manuf Sci E-T ASME 25(2):245–254

Wu CW, Tang CH, Chang CF, Shiao YS (2012) Thermal error compensation method for machine center. Int J Adv Manuf Technol 59(5–8):681–689

Lin ZC, Chang JS (2007) The building of spindle thermal displacement model of high speed machine center. Int J Adv Manuf Technol 34(5–6):556–566

Li Y, Zhao W, Wu W, Lu B, Chen Y (2014) Thermal error modeling of the spindle based on multiple variables for the precision machine tool. Int J Adv Manuf Technol 72(9–12):1415–1427

Creighton E, Honegger A, Tulsian A, Mukhopadhyay D (2010) Analysis of thermal errors in a high-speed micro-milling spindle. Int J Mach Tools Manuf 50(4):386–393

Zhang J, Feng P, Chen C, Yu D, Wu Z (2013) A method for thermal performance modeling and simulation of machine tools. Int J Adv Manuf Technol 68(5–8):1517–1527

Zhang Y, Yang JG, Xiang ST, Xiao HX (2013) Volumetric error modeling and compensation considering thermal effect on five-axis machine tools. Proc IMechE, Part C: J Mech Eng Sci 227(5):1102–1115

Liu YL, Lu Y, Gao D, Hao ZP (2013) Thermally induced volumetric error modeling based on thermal drift and its compensation in Z-axis. Int J Adv Manuf Technol 69(9–12):2735–2745

Furukawa Y, Moronuki N (1987) Contact deformation of a machine tool slideway and its effect on machining accuracy: vibration, control engineering, engineering for industry. JSME I J: Bull JSME 30(263):868–874

Yang S, Yuan J, Ni J (1997) Real-time cutting force induced error compensation on a turning center. Int J Mach Tools Manuf 37(11):1597–1610

Wu H, Chen HJ, Meng P, Yang JG (2010) Modelling and real-time compensation of cutting-force-induced error on a numerical control twin-spindle lathe. Proc I MechE Part B: J Eng Manuf 224(4):567–577

Fan KC, Chen HM, Kuo TH (2012) Prediction of machining accuracy degradation of machine tools. Precis Eng 36(2):288–298

Xiang ST, Zhu XL, Yang JG (2014) Modeling for spindle thermal error in machine tools based on mechanism analysis and thermal basic characteristics tests. Proc I MechE Part C: J Mech Eng Sci 228(18):3381–3394

Lu YX, Islam MN (2012) A new approach to thermally induced volumetric error compensation. Int J Adv Manuf Technol 62(9–12):1071–1085

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools—a review part II: thermal errors. Int J Mach Tools Manuf 40(9):1257–1284

Cohen J, Cohen P, West SG, Aiken LS (2003) Applied multiple regression/correlation analysis for the behavioral sciences (3rd ed.). Mahwah, NJ: Erlbaum

Durand RM, Sharma S, Gur-Arie O (1981) Identification and analysis of moderator variables. J Mark Res 18(3):291–300

Uriarte L, Zatarain M, Axinte D, Yague-Fabra J, Ihlenfeldt S, Eguia J, Olarra A (2013) Machine tools for large parts. CIRP Ann Manuf Technol 62(2):731–750

Ekinci TO, Mayer JRR (2007) Relationships between straightness and angular kinematic errors in machines. Int J Mach Tools Manuf 47(12–13):1997–2004

Liao JS, Lai JM, Chieng WH (1997) Modeling and analysis of nonlinear guideway for double-ball bar (DBB) measurement and diagnosis. Int J Mach Tools Manuf 37(5):687–707

Lee JH, Yang SH (2005) Measurement of geometric errors in a miniaturized machine tool using capacitance sensors. J Mater Process Tech 164–165:1402–1409

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiang, S., Yang, J. Error map construction and compensation of a NC lathe under thermal and load effects. Int J Adv Manuf Technol 79, 645–655 (2015). https://doi.org/10.1007/s00170-015-6852-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6852-5