Abstract

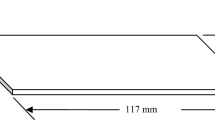

This paper develops a framework that tackles the Pareto optimum of injection process parameters for multi-objective optimization of the quality of plastic part. The processing parameters such as injection time, melt temperature, packing time, packing pressure, cooling temperature, and cooling time are studied as model variables. The quality of plastic part is measured by warp, volumetric shrinkage, and sink marks, which is to be minimized. The two-stage optimization system is proposed in this study. In the first stage, an improved efficient global optimization (IEGO) algorithm is adopted to approximate the nonlinear relationship between processing parameters and the measures of the part quality. In the second stage, non-dominated sorting-based genetic algorithm II (NSGA-II) is used to find a much better spread of design solutions and better convergence near the true Pareto optimal front. A cover of liquid crystal display part is optimized to show the method. The results show that the Pareto fronts obtained by NSGA-II are distributed uniformly, and this algorithm has good convergence and robustness. The pair-wise Pareto frontiers show that there is a significant trade-off between warpage and volumetric shrinkage, and there is no significant trade-off between sink marks and volumetric shrinkage and between sink marks and warpage.

Similar content being viewed by others

References

Dang XP (2014) General frameworks for optimization of plastic injection molding process parameters. Simul Model Pract Theory 41(2):15–27

Wang YQ, Kim JG, Song JI (2014) Optimization of plastic injection molding process parameters for manufacturing a brake booster valve body. Mater Des 56(4):313–317

Farshi B, Gheshmi S, Miandoabchi E (2011) Optimization of injection molding process parameters using sequential simplex algorithm. Mater Des 32(1):414–423

Wang R, Zeng J, Feng X, Xia Y (2013) Evaluation of effect of plastic injection molding process parameters on shrinkage based on neural network simulation. J Macromol Sci B 52(1):206–221

Yin F, Mao H, Hua L (2011) A hybrid of back propagation neural network and genetic algorithm for optimization of injection molding process parameters. Mater Des 32(6):3457–3464

Mehat NM, Kamaruddin S (2011) Multi-response optimization of injection moulding processing parameters using the Taguchi method. Polym Plast Technol Eng 50(15):1519–1526

Deng YM, Lam YC, Britton GA (2004) Optimization of injection moulding conditions with user-definable objective functions based on a genetic algorithm. Int J Prod Res 42(7):1365–1390

Huang CC, Tang TT (2005) Parameter optimization in melt spinning by neural networks and genetic algorithms. Int J Adv Manuf Technol 27(11–12):1113–1118

Hsu CM, Su CT, Liao D (2003) A novel approach for optimizing the optical performance of the broadband tap coupler. Int J Syst Sci 34(3):215–226

Wei Z, Feng YX, Tan JR, Wang J-l, Z-k L (2008) Multi-objective performance optimal design of large-scale injection molding machine. Int J Adv Manuf Technol 41(3–4):242–249

Wei Z, Yang D, Wang X, Wang J (2009) Multi-objectives optimal model of heavy equipment using improved Strength Pareto Evolutionary Algorithm. Int J Adv Manuf Technol 45(3–4):389–396

Ferreira I, Weck O, Saraiva P, Cabral J (2009) Multidisciplinary optimization of injection molding systems. Struct Multidiscip Optim 41(4):621–635

Ferreira I, Cabral JA, Saraiva P, Oliveira MC (2013) A multidisciplinary framework to support the design of injection mold tools. Struct Multidiscip Optim 49(3):501–521

Martin JD, Simpson TW (2005) Use of Kriging models to approximate deterministic computer models. AIAA J 43(4):853–863

Lophaven SN, Nielsen HB, Sondergaard J (2002) DACE: a MATLAB Kriging toolbox, version 2.0. Informatics and Mathematical Modeling, Technical University of Denmark

Jones DR, Schonlau M, Welch WJ (1998) Efficient global optimization of expensive black-box functions. J Global Optim 13(4):455–492

Shi HZ, Xie SM, Wang XC (2013) A warpage optimization method for injection molding using artificial neural network with parametric sampling evalution strategy. Int J Adv Manuf Technol 65(1–4):343–353

AlKaabneh FA, Barghash M, Mishael I (2012) A combined analytical hierarchical process (AHP) and Taguchi experimental design (TED) for plastic injection molding process settings. Int J Adv Manuf Technol 66(5–8):679–694

Mathivanan D, Parthasarathy NS (2009) Prediction of sink depths using nonlinear modeling of injection molding variables. Int J Adv Manuf Technol 43(7–8):654–663

Guo W, Hua L, Mao HJ (2014) Minimization of sink mark depth in injection-molded thermoplastic through design of experiments and genetic algorithm. Int J Adv Manuf Technol 72(1–4):365–375

Deb K, Pratap A, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: NSGA- II. IEEE Trans Evol Comput 6(2):182–197

Fallah N, Honarparast S (2013) NSGA-II based multi-objective optimization in design of Pall friction dampers. J Constr Steel Res 89(10):75–85

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, J., Cheng, G., Ruan, S. et al. Multi-objective optimization design of injection molding process parameters based on the improved efficient global optimization algorithm and non-dominated sorting-based genetic algorithm. Int J Adv Manuf Technol 78, 1813–1826 (2015). https://doi.org/10.1007/s00170-014-6770-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6770-y