Abstract

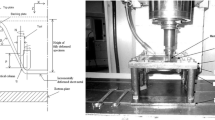

Single-point incremental forming (SPIF) is an emerging sheet forming process. The force-parameter correlation is yet not well clear in this process, specifically for geometries with corners. In the present study, a new level of understanding on the parameter-force relationship is presented. A simple shape with corners (i.e., frustum of pyramid containing corners and oblique wall) is opted as the test geometry. Following the response surface method, a design of experiments (DoE) comprising of 47 runs obtained by varying five forming parameters namely sheet thickness, tool diameter, wall angle, step size, and flow stress is performed. The analysis of the results reveals that the parameter-force relation in SPIF is complex and interactive, explaining that the effect of variation in a parameter on the force magnitude is closely associated with the value and the type of the other parameters employed for forming. From the analysis of the forces involved in forming the pyramid, it is found that the corner requires more force than does the wall. Further, the normal force (i.e., force along normal to sheet plane) is greater than the in-plane force. The use of very small tools, especially low d/t o where d is the tool diameter and t o is the sheet thickness, is observed to cause fabrication defects leading to substantial rise in the magnitude of forming force thus endangering the machine tool. Finally, a set of force models is proposed using which one can predict a set of forming parameters simultaneously minimizing the force and preventing the fabrication problems.

Similar content being viewed by others

References

Lim WS, Choi HS, Ahn SY, Kim BM (2014) Cooling channel design of hot stamping tools for uniform high-strength components in hot stamping process. Int J Adv Manuf Tech 70:1189–1203

Hsu TJ (1974) Present scope and future trend of sheet metal forming research. Int J Prod Res 12(1):99–115

Hagan E, Jeswiet J (2003) A review of conventional and modern single-point sheet metal forming methods. P I Mech Eng B-J Eng 217:213–225

Echrif SBM, Hrairi M (2011) Research and progress in incremental sheet forming processes. Mater Manuf Process 26:1404–1414

Li M, Li Z, Mo JH, Lu Y (2012) Tool-path generation for sheet metal incremental forming based on STL model with defects. Int J Adv Manuf Tech 63:535–547

Silva MB, Nielsen PS, Bay N, Martins PAF (2011) Failure mechanisms in single point incremental forming of metals. Int J Adv Manuf Tech 56:893–903

Hussain G, Gao L, Zhang ZY (2008) Formability evaluation of the pure titanium sheet in the cold incremental forming process. Int J Adv Manuf Tech 37:920–926

Ziran X, Gao L, Hussain G, Cui Z (2010) The performance of flat end and hemispherical end tools in single-point incremental forming. Int J Adv Manuf Tech 46:1113–1118

Hussain G, Gao L, Hayat N, Dar NU (2010) The formability of annealed and pre-aged AA-2024 sheets in single-point incremental forming. Int J Adv Manuf Tech 46:543–549

Amino H, Lu Y, Ozawa S, Fakuda K, Maki T (2002) Dieless NC forming of automotive service panels. In: Proceeding of the conference on advanced technology of plasticity, JSTP Japan, p 1015–1020

Ambrogio G, Napoli LD, Filice L, Gagliardi F, Muzzupappa M (2005) Application of incremental forming process for highly customized medical product manufacturing. J Mater Process Tech 162–163:156–162

Ambrogio G, Filice L, Gagliardi F (2012) Improving industrial suitability of incremental sheet forming process. Int J Adv Manuf Tech 58:941–947

Fan G, Sun F, Meng X, Gao L, Tong G (2010) Electric hot incremental forming of Ti-6Al-4V titanium sheet. Int J Adv Manuf Tech 49:941–947

Li J, Bai T, Zhou Z (2014) Numerical simulation and experimental investigation of incremental sheet forming with an elastic support. Int J Adv Manuf Tech. doi:10.1007/s00170-014-6117-8

Iseki H (2001) An approximate deformation analysis and FEM analysis for the incremental bulging of sheet metal using a spherical roller. J Mater Process Tech 11:150–154

Silva MB, Skjoedt M, Martins PAF, Bay N (2008) Revisiting the fundamentals of single point incremental forming by means of membrane analysis. Int J Mach Tool Manu 48:73–83

Bagudanch I, Centeno G, Vallellano C, Garcia ML (2013) Forming forces in single point incremental forming under different bending conditions. In: Proceedings of 5th Manufacturing Engineering Society International Conference, Zaragoza. Pages not available

Ambrogio G, Filice L, Micari F (2006) A force measuring based strategy for failure prevention in incremental forming. J Mater Process Tech 117:413–416

Arfa H, Bahloul R, Bel HSH (2012) Finite element modelling and experimental investigation of single point incremental forming process of aluminum sheets: influence of process parameters on punch force monitoring and on mechanical and geometrical quality of parts. Int J Mater Form. doi:10.1007/s12289-012-1101-z

Henrard C, Bouffioux C, Eyckens P, Sol H, Duflou JR, Van HP, Van-Bael A, Duchêne L, Habraken AM (2011) Forming forces in single point incremental forming: prediction by finite element simulations, validation and sensitivity. Comput Mech 47:573–590

Duflou JR, Tunçkol Y, Szekeres A, Vanherck P (2007) Experimental study on force measurements for single point incremental forming. J Mater Process Tech 189:65–72

Aerens R, Eyckens P, Van-Bael A, Duflou JR (2009) Force prediction for single point incremental forming deduced from experimental and FEM observations. Int J Adv Manuf Tech. doi:10.1007/s00170-009-2160-2

Hussain G, Gao L, Hayat N (2007) A new parameter and its effect on the formability in single point incremental forming: a fundamental investigation. J Mech Sci Technol 24:1–7

Centeno G, Bagudanch I, Martinez DAJ, Garcia RML, Vallellano C (2014) Critical analysis of necking and fracture limit strains and forming forces in single-point incremental forming. Mater Des 63:20–29

Hussain G, Khan HR, Hayat N (2013) Guidelines for tool size selection for SPIF of an aerospace alloy. Mater Manuf Process 28:324–329

Montgomery DC (1997) Design and analysis of experiments, 4th edn. Wiley, New York

Al-Ghamdi KA, Hussain G (2014) Threshold tool-radius condition maximizing the formability in SPIF considering a variety of materials: experimental and FE investigations. Int J Mach Tool Manuf (Submitted)

Hussain G, Al-Ghamdi KA, Khalatbari H, Iqbal A, Hashemipoure M (2013) Forming parameters and forming defects in incremental forming: Part B. Mater Manuf Process (Accepted)

Anderson MJ, Whitcomb PJ (2004) RSM simplified: optimizing processes using response surface methods for design of experiments. Taylor & Francis, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Ghamdi, K.A., Hussain, G. Forming forces in incremental forming of a geometry with corner feature: investigation into the effect of forming parameters using response surface approach. Int J Adv Manuf Technol 76, 2185–2197 (2015). https://doi.org/10.1007/s00170-014-6409-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6409-z