Abstract

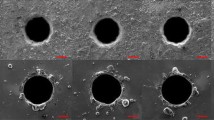

Laser machining on metals is based on heat effect on most occasions, so resolidified material can hardly be avoided. In laser drilling, the laser-induced burr deposition on the exit rim is one of the resolidified materials, and the amount of which directly affects the hole quality, but unfortunately it has not been especially studied in the past. The objective of this work is to study the experimental characterizations of burr deposition on different drilling conditions, to shed light upon the mechanism of burr formation in laser trepan drilling, and to minimize it under the available experimental conditions. The effects of seven processing parameters are respectively studied by single-factor experiments, and the optimum combination of parameters which yields the minimum burr is determined by the Taguchi method. The final drilling result shows that the burr deposition has largely been reduced.

Similar content being viewed by others

References

Phipps C (2003) Overview of laser applications: the state of the art and the future trend. Proc SPIE 4830:1–10

Zhang Y, Faghri A (1999) Vaporization, melting and heat conduction in laser drilling process. Int J Heat Mass Transfer 43:1775–1790

Wang XY, Ng GKL, Liu Z, Li L, Bradly L (2004) EPMA microanalysis of recast layers produced during laser drilling of type 305 stainless steel. Thin Solid Films 453–454:84–88

Low DKY, Li L, Corfe AG (2000) The influence of assist gas on the mechanism of material ejection and removal during laser percussion drilling. Proc Inst Mech Eng B 214:521–527

Low DKY, Li L, Corfe AG, Byrd PJ (2001) Spatter-free laser percussion drilling of closely spaced array holes. Int J Mach Tools Manuf 41:361–377

Chien WT, Hou SC (2007) Investigating the recast layer formed during the laser trepan drilling of Inconel 718 using the Taguchi method. Int J Adv Manuf Technol 33:308–316

Mishra S, Yadava V (2013) Modeling and optimization of laser beam percussion drilling of nickel-based superalloy sheet using Nd: YAG laser. Opt Lasers Eng 51:681–695

Yeo SH, Ngoi BKA, Chua LY (1997) Ultrasonic deburring. Int J Adv Manuf Technol 13:333–334

Fohl C, Breitlin D, Jasper K, Radtke J, Dausinger F (2002) Precise drilling of metal and ceramics with short and ultrashort pulse solid state lasers. Proc SPIE 4426:104–107

Nowakowski KA (2005) Laser beam interaction with materials for microscale applications. Worcester Polytechnic Institute, Massachusetts

Ng GKL, Crouse PL, Li L (2006) An analytical model for laser drilling incorporating effects of exothermic reaction, pulse width and hole geometry. Int J Heat Mass Transfer 49:1358–1374

Voisey KT, Cheng CF, Clyne TW (2000) Quantification of melt ejection phenomena during laser drilling. Met Res Soc Symp 617:J5.6.1–J5.6.7

Bandyopadhyay S, Sarin Sundar JK, Sundararajan G, Joshi SV (2002) Geometrical features and metallurgical characteristics of Nd:YAG laser drilled holes in thick IN718 and Ti-6Al-4V sheets. J Mater Proc Technol 127(1):83–95

Voisey KT, Kudesia SS, Rodden WSO, Hand DP, Jones JDC, Clyne TW (2003) Melt ejection during laser drilling of metals. Mater Sci Eng A256:414–424

Yilbas BS (1997) Parametric study to improve to improve laser hole drilling process. J Mater Process Technol 70:264–273

Mishra S, Yadava V (2013) Modeling and optimization of laser beam percussion drilling of thin aluminum sheet. Opt Lasers Eng 48:461–474

Reg Y, Leitz KH, Schmidt M (2011) Influence of processing gas on the ablation quality at ns-laser beam ablation. Phys Procedia 12:182–187

Allmen MV (1976) Laser drilling velocity in metals. J Appl Phys 47(12):5460–5463

Yilbas BS (1998) Particle ejection during laser drilling of engineering metals. Lasers Eng 7:57–67

Ross PJ (1989) Taguchi techniques for quality engineering. McGraw-Hill, New York

Bendell A, Disney J, Pridmore WA (1989) Taguchi methods: applications in world industry. IFS, UK

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duan, W., Wang, K., Dong, X. et al. Experimental characterizations of burr deposition in Nd:YAG laser drilling: a parametric study. Int J Adv Manuf Technol 76, 1529–1542 (2015). https://doi.org/10.1007/s00170-014-6377-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6377-3