Abstract

This study proposes the SIMP-based topology optimization which can design a high-torque synchronous reluctance motor (SynRM) in an efficient way. Although it is crucial to simultaneously optimize a SynRM design and the corresponding current-phase angle for the maximum performance, most studies to date have conducted design optimization at a fixed current-phase angle for simplicity. It is also difficult to consider the magnetic nonlinearity and complicated design features in topology optimization. To solve the above issue, this study expresses the optimal current-phase angle (β(MTPA)) for the SynRM as a function of design variables (ρ). To efficiently determine β(MTPA)(ρ), the average torque curve is interpolated by using the modified Akima method. For interpolation, three-time electromagnetic finite element (FE) analyses are conducted at every iteration. The structural FE analysis is also performed at every iteration to obtain a structurally meaningful design. Through the above procedure, the SynRM design and the corresponding current excitation can be simultaneously optimized. Optimization results are discussed in terms of computational accuracy and efficiency, compared with other methods.

Similar content being viewed by others

Abbreviations

- SynRM:

-

Synchronous reluctance motor

- MTPA:

-

Maximum torque per ampere

- SIMP:

-

Solid isotropic material with penalization

- FE:

-

Finite element

- Β :

-

The continuous current-phase angle

- β k :

-

The k-th discrete current-phase angle

- β k(ρ):

-

The k-th discrete current phase angle (design-dependent)

- β (MTPA) :

-

A specific optimal current phase angle

- β (MTPA)(ρ):

-

A specific optimal current phase angle (design-dependent)

- : = :

-

A sign inserting the right term into the left term

References

Akima H (1970) A new method of interpolation and smooth curve fitting based on local procedures. J ACM (JACM) 17(4):589–602

Ali MA, Shimoda M (2022a) Toward multiphysics multiscale concurrent topology optimization for lightweight structures with high heat conductivity and high stiffness using MATLAB. Struct Multidisc Optim 65(7):207

Ali MA, Shimoda M (2022b) Investigation of concurrent multiscale topology optimization for designing lightweight macrostructure with high thermal conductivity. Int J Therm Sci 179:107653

Arora JS (2004) Introduction to optimum design. Elsevier, Amsterdam

Babetto C, Bacco G, Bianchi N (2018) Synchronous reluctance machine optimization for high-speed applications. IEEE Trans Energy Convers 33(3):1266–1273

Bendsøe MP (1989) Optimal shape design as a material distribution problem. Struct Optim 1(4):193–202

Bianchi N, Bolognani S, Carraro E, Castiello M, Fornasiero E (2016) Electric vehicle traction based on synchronous reluctance motors. IEEE Trans Ind Appl 52(6):4762–4769

Choi JS, Yoo J (2008) Structural optimization of ferromagnetic materials based on the magnetic reluctivity for magnetic field problems. Comput Methods Appl Mech Eng 197(49):4193–4206

Credo A, Fabri G, Villani M, Popescu M (2020a) A robust design methodology for synchronous reluctance motors. IEEE Trans Energy Convers 35(4):2095–2105

Credo A, Fabri G, Villani M, Popescu M (2020b) Adopting the topology optimization in the design of high-speed synchronous reluctance motors for electric vehicles. IEEE Trans Ind Appl 56(5):5429–5438

Cupertino F, Pellegrino G, Gerada C (2014) Design of synchronous reluctance motors with multiobjective optimization algorithms. IEEE Trans Ind Appl 50(6):3617–3627

Ding H, Zhu H, Hua Y (2018) Optimization design of bearingless synchronous reluctance motor. IEEE Trans Appl Supercond 28(3):1–5

Dzierżanowski G (2012) On the comparison of material interpolation schemes and optimal composite properties in plane shape optimization. Struct Multidisc Optim 46:693–710

Farhadian M, Moallem M, Fahimi B (2022) Multimodal optimization algorithm for torque ripple reduction in synchronous reluctance motors. IEEE Access 10:26628–26636

Ferrari M, Doria A, Fornasiero E (2015) Design of synchronous reluctance motor for hybrid electric vehicles. IEEE Trans Ind Appl 51(4):3030–3040

Fritsch FN, Carlson RE (1980) Monotone piecewise cubic interpolation. SIAM J Numer Anal 17(2):238–246

Garibaldi M, Gerada C, Ashcroft I, Hague R (2019) Free-form design of electrical machine rotor cores for production using additive manufacturing. J Mech Des. https://doi.org/10.1115/1.4042621

Guo F, Brown IP (2020) Simultaneous magnetic and structural topology optimization of synchronous reluctance machine rotors. IEEE Trans Magn 56(10):1–12

Jang IG, Kim IY (2008) Computational study of Wolff’s law with trabecular architecture in the human proximal femur using topology optimization. J Biomech 41(11):2353–2361

Jang IG, Kim IY, Kwak BM (2009) Analogy of strain energy density based bone-remodeling algorithm and structural topology optimization. J Biomech Eng 131(1):011012

Jang IG, Kim K, Kwak BM (2014) Conceptual and basic designs of the Mobile Harbor crane based on topology and shape optimization. Struct Multidisc Optim 50(3):505–515

Kahaner D, Moler C, Nash S (1989) Numerical methods and software. Prentice-Hall Inc, Hoboken

Kim YS, Park IH (2010) Topology optimization of rotor in synchronous reluctance motor using level set method and shape design sensitivity. IEEE Trans Appl Supercond 20(3):1093–1096

Kim KC, Ahn JS, Won SH, Hong JP (2007) A study on the optimal design of SynRM for the high torque and power factor. IEEE Trans Magn 43(6):2543–2545

Lee C, Jang IG (2021) Topology optimization of multiple-barrier synchronous reluctance motors with initial random hollow circles. Struct Multidisc Optim 64(4):2213–2224

Lee C, Jang IG (2022) Topology optimization framework for simultaneously determining the optimal structural design and current phase angle of the IPMSMs for the MTPA control. IEEE Trans Ind Electron. https://doi.org/10.1109/TIE.2022.3174240

Lee C, Lee J, Jang IG (2022) Topology optimization for the manufacturable and structurally safe synchronous reluctance motors with multiple iron webs and bridges. IEEE Trans Ind Electron 70(1):678–687

Lim S, Yamada T, Min S, Nishiwaki S (2011) Topology optimization of a magnetic actuator based on a level set and phase-field approach. IEEE Trans Magn 47(5):1318–1321

Lim S, Min S, Hong JP (2012) Low torque ripple rotor design of the interior permanent magnet motor using the multi-phase level-set and phase-field concept. IEEE Trans Magn 48(2):907–910

Nardo MD, Calzo GL, Galea M, Gerada C (2017) Design optimization of a high-speed synchronous reluctance machine. IEEE Trans Ind Appl 54(1):233–243

Okamoto Y, Hoshino R, Wakao S, Tsuburaya T (2017) Improvement of torque characteristics for a synchronous reluctance motor using MMA-based topology optimization method. IEEE Trans Magn 54(3):1–4

Park RH (1929) Two-reaction theory of synchronous machines generalized method of analysis-part I. Trans Am Inst Electr Eng 48(3):716–727

Park SI, Min S (2009) Magnetic actuator design for maximizing force using level set based topology optimization. IEEE Trans Magn 45(5):2336–2339

Park IH, Lee B, Hahn S (1992) Design sensitivity analysis for nonlinear analysis for magnetostatic problems using finite element method. IEEE Trans Magn 28(2):1533–1536

Park S, Lee J, Lee J (2021) Multi-material topology optimization of permanent magnet synchronous motors. Int J Appl Electromagn Mech 67(4):461–472

Rozvany GIN (2001) Aims, scope, methods, history and unified terminology of computer-aided topology optimization in structural mechanics. Struct Multidisc Optim 21:90–108

Sanada M, Hiramoto K, Morimoto S, Takeda Y (2004) Torque ripple improvement for synchronous reluctance motor using an asymmetric flux barrier arrangement. IEEE Trans Ind Appl 40(4):1076–1082

Sigmund O, Maute K (2013) Topology optimization approaches: a comparative review. Struct Multidisc Optim 48(6):1031–1055

Svanberg K (1987) The method of moving asymptotes-a new method for structural optimization. Int J Numer Method Eng 24(2):359–373

Vagati A, Pastorelli M, Scapino F, Franceshini G (2000) Impact of cross saturation in synchronous reluctance motors of the transverse-laminated type. IEEE Trans Ind Appl 36(4):1039–1046

Xu L, Xu X, Lipo TA, Novotny DW (1991) Vector control of a synchronous reluctance motor including saturation and iron loss. IEEE Trans Ind Appl 27(5):977–985

Yamashita Y, Okamoto Y (2020) Design optimization of synchronous reluctance motor for reducing iron loss and improving torque characteristics using topology optimization based on the level-set method. IEEE Trans Magn 56(3):1–4

Acknowledgements

This work was partly supported by the National Research Foundation of Korea (NRF) grant funded by the Korean Government (MSIT) (2021R1A2C2009860).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Replication of results

All the presented results can be replicated, and all the necessary data sets and a flowchart for the problems are presented in the manuscript. The software used in this study is protected by the National Research Foundation of Korea (NRF). We are confident that sufficient details on methodology and implementation are contained in this paper, and readers who have difficulties and questions about replicating the results are welcome to contact the authors.

Additional information

Responsible Editor: Shikui Chen.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Analytical sensitivity analysis

Appendix A: Analytical sensitivity analysis

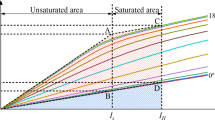

1.1 Modified Akima method-based sensitivity

In Fig. 4, the analytical sensitivities of the average torque at β4, β5, and β6 can be calculated using the adjoint variable method (Choi and Yoo 2008). Note that the sensitivities of the average torque at β3 = 0° and β7 = 90° become zero. In addition, the sensitivities of the average torque at β1, β2, β8, and β9 can be obtained by using the modified Akima method (Akima 1970), as follows:

1.2 Sensitivity of the interpolated average torque (corresponding to Step 1 in Sect. 3.3 )

Within each interval of [βk, βi+1), the analytical sensitivity of the interpolated curve (Tavg(ρ, β)) with respect to a design variable (ρe) can be expressed, as follows:

where

Here, the sensitivity of tk(ρ) can be evaluated, as follows:

1.3 Sensitivity of the average torque at the optimal current phase angle (corresponding to Step 2 in Sect. 3.3 )

If βc is selected as β(MTPA)(ρ), the final term in Eq. (A.2) can be expressed, as follows:

where

In the above equations, ∂βc/∂a, ∂βc/∂b, and ∂βc/∂c can be easily obtained by using Eqs. (17)–(20).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, C., Jang, I.G. Computationally efficient topology optimization for the SynRMs based on the torque curve interpolation. Struct Multidisc Optim 66, 172 (2023). https://doi.org/10.1007/s00158-023-03623-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-023-03623-8