Abstract

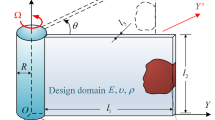

Apart from mechanical actions, structural components in the construction industry may be subjected to a thermal gradient, causing (internally) restrained thermal expansion. These thermal loads can alter the mechanical response of components in a structural topology optimization procedure. Therefore, the influence of thermal loading should be considered in the sensitivity analysis to efficiently update the structural layout of material. In this paper, a density-based topology optimization procedure is developed for compliance minimization of structural components subjected to thermo-mechanical loads considering steady-state heat conduction and weak thermo-mechanical coupling. The adjoint method is employed to obtain the analytical sensitivities, taking into account the influence of the design-dependent temperature field and thermal properties. The proposed topology optimization procedure is demonstrated on the MBB problem, extended with thermal loading, to investigate the influence of the proposed sensitivities on the optimized results. Furthermore, the thermo-mechanical load ratio is quantitatively defined and its effect on the resulting topologies is studied. The results show that the thermo-mechanical load ratio significantly changes the topology of the optimized results. Finally, the topology optimization procedure is presented in an efficient 138-line MATLAB code and provided as supplementary material, serving as a basis for further research.

Similar content being viewed by others

References

Allaire G (2015) A review of adjoint methods for sensitivity analysis, uncertainty quantification and optimization in numerical codes. Ingénieurs De L’automobile 836:33–36

Andreassen E, Clausen A, Schevenels M, Lazarov BS, Sigmund O (2011) Efficient topology optimization in MATLAB using 88 lines of code. Struct Multidisc Optim 43(1):1–16. https://doi.org/10.1007/s00158-010-0594-7

Andrew R (2018) Global CO2 emissions from cement production, 1928–2017. Earth Syst Sci Data 10:195–217. https://doi.org/10.5281/zenodo.831455

Bendsøe M, Sigmund O (2003) Topology optimization: theory, methods and applications. Springer, Berlin. https://doi.org/10.1007/978-3-662-05086-6

Bourdin B, Chambolle A (2003) Design-dependent loads in topology optimization. ESAIM 9:247–273. https://doi.org/10.1051/COCV:2002070/

Bruyneel M, Duysinx P (2005) Note on topology optimization of continuum structures including self-weight. Struct Multidisc Optim 29(4):245–246. https://doi.org/10.1007/s00158-004-0484-y

Chen BC, Kikuchi N (2001) Topology optimization with design-dependent loads. Finite Elem Anal Des 37(1):57–70. https://doi.org/10.1016/S0168-874X(00)00021-4

Chen Y, Ye L, Zhang YX, Yang C (2021) A multi-material topology optimization with temperature-dependent thermoelastic properties. Eng Optim 54(12):2140–2155. https://doi.org/10.1080/0305215X.2021.1977291

Chen J, Zhao Q, Zhang L (2022) Multi-material topology optimization of thermo-elastic structures with stress constraint. Mathematics 10(8):1216. https://doi.org/10.3390/MATH10081216

Cho S, Choi JY (2005) Efficient topology optimization of thermo-elasticity problems using coupled field adjoint sensitivity analysis method. Finite Elem Anal Des 41(15):1481–1495. https://doi.org/10.1016/j.finel.2005.05.003

Deaton JD, Grandhi RV (2013) Stiffening of restrained thermal structures via topology optimization. Struct Multidisc Optim 48(4):731–745. https://doi.org/10.1007/s00158-013-0934-5

Deaton JD, Grandhi RV (2014) A survey of structural and multidisciplinary continuum topology optimization: post 2000. Struct Multidisc Optim 49(1):1–38. https://doi.org/10.1007/s00158-013-0956-z

Diaz A, Benard A (2003) Topology optimization of heat-resistant structures. In: ASME 2003 international design engineering technical conferences and computers and information in engineering conference. https://doi.org/10.1115/DETC2003/DAC-48769

Ganobjak M, Carstensen J (2019) Topology-optimized insulating facebrick with aerogel filling. J Phys 1343:12195. https://doi.org/10.1088/1742-6596/1343/1/012195

Gao T, Zhang W (2010) Topology optimization involving thermo-elastic stress loads. Struct Multidisc Optim 42(5):725–738. https://doi.org/10.1007/S00158-010-0527-5

Gao T, Xu P, Zhang W (2016) Topology optimization of thermo-elastic structures with multiple materials under mass constraint. Comput Struct 173:150–160. https://doi.org/10.1016/j.compstruc.2016.06.002

Giraldo-Londoño O, Mirabella L, Dalloro L, Paulino GH (2020) Multi-material thermomechanical topology optimization with applications to additive manufacturing: design of main composite part and its support structure. Comput Methods Appl Mech Eng 363:112812. https://doi.org/10.1016/J.CMA.2019.112812

Gonçalves M, Dias-de-Oliveira JA, Valente R (2022) A new bidirectional algorithm for topology optimization of thermoelastic structural problems. Int J Mech Mater Des 18(2):309–325. https://doi.org/10.1007/s10999-022-09591-z

Hammer VB, Olhoff N (2000) Topology optimization of continuum structures subjected to pressure loading. Struct Multidisc Optim 19(2):85–92. https://doi.org/10.1007/S001580050088

Hou J, Zhu J-H, Li Q (2016) On the topology optimization of elastic supporting structures under thermomechanical loads. Int J Aerosp Eng. https://doi.org/10.1155/2016/7372603

Huang X, Xie YM (2011) Evolutionary topology optimization of continuum structures including design-dependent self-weight loads. Finite Elem Anal Des 47(8):942–948. https://doi.org/10.1016/J.FINEL.2011.03.008

Leader MK (2021) Stress-based topology optimization for steady-state and transient thermoelastic design [PhD thesis].

Lee E, Martins JRRA (2012) Structural topology optimization with design-dependent pressure loads. Comput Methods Appl Mech Eng 233–236:40–48. https://doi.org/10.1016/j.cma.2012.04.007

Lewis RW, Nithiarasu P, Seetharamu KN (2004) Fundamentals of the finite element method for heat and fluid flow. Wiley, New York. https://doi.org/10.1002/0470014164

Li Q, Steven GP, Xie YM (2001) Thermoelastic topology optimization for problems with varying temperature fields. J Therm Stresses 24(4):347–366. https://doi.org/10.1080/01495730151078153

Li D, Zhang X, Guan Y, Zhan J (2010) Topology optimization of thermo-mechanical continuum structure. In: IEEE/ASME international conference on advanced intelligent mechatronics, AIM, pp 403–408. https://doi.org/10.1109/AIM.2010.5695845

Logan DL (2016) A first course in the finite element method, 6th edn. Thomson, Toronto

Ooms T, Vantyghem G, Thienpont T, Van Coile R, De Corte W (2022) Different approaches for topology optimization of building structures subjected to thermo-mechanical loads due to fire. In ACSMO 2022, Asian Congress of structural and multidisciplinary optimization 2022, proceedings, 8. https://acsmo2022.org/

Pedersen P, Pedersen NL (2012) Interpolation/penalization applied for strength design of 3D thermoelastic structures. Struct Multidisc Optim 45(6):773–786. https://doi.org/10.1007/s00158-011-0755-3

Picelli R, Vicente W, Pavanello R (2015) Bi-directional evolutionary structural optimization for design-dependent fluid pressure loading problems. Eng Optim 47(10):1324–1342. https://doi.org/10.1080/0305215X.2014.963069

Picelli R, Neofytou A, Kim HA (2019) Topology optimization for design-dependent hydrostatic pressure loading via the level-set method. Struct Multidisc Optim 60(4):1313–1326. https://doi.org/10.1007/S00158-019-02339-Y

Reddy JN, Gartling DK (2010) The finite element method in heat transfer and fluid dynamics, 3rd edn. CRC Press, Boca Raton

Rodrigues H, Fernandes P (1995) A material based model for topology optimization of thermoelastic structures. Int J Numer Methods Eng 38(12):1951–1965. https://doi.org/10.1002/NME.1620381202

Sigmund O (2007) Morphology-based black and white filters for topology optimization. Struct Multidisc Optim 33(4):401–424. https://doi.org/10.1007/s00158-006-0087-x

Stoiber N, Kromoser B (2021) Topology optimization in concrete construction: a systematic review on numerical and experimental investigations. Struct Multidisc Optim 64(4):1725–1749. https://doi.org/10.1007/S00158-021-03019-6

Stolpe M, Svanberg K (2001) An alternative interpolation scheme for minimum compliance topology optimization. Struct Multidisc Optim 22:116–124. https://doi.org/10.1007/s001580100129

Svanberg K (1987) The method of moving asymptotes - a new method for structural optimization. Int J Numer Methods Eng 24(2):359–373. https://doi.org/10.1002/nme.1620240207

Svanberg K (2007) MMA and GCMMA-two methods for nonlinear optimization, pp 1–15. https://people.kth.se/~krille/gcmma07.pdf

Tang L, Gao T, Song L, Meng L, Zhang C, Zhang W (2019) Topology optimization of nonlinear heat conduction problems involving large temperature gradient. Comput Methods Appl Mech Eng 357:112600. https://doi.org/10.1016/j.cma.2019.112600

Tortorelli DA, Michaleris P (1994) Design sensitivity analysis: overview and review. Inverse Probl Eng 1(1):71–105. https://doi.org/10.1080/174159794088027573

Van Den Hende K, Van Paepegem W (2021) Multi-materiaal topologie optimalisatie van structurele onderdelen onder thermomechanische belastingen [MSc thesis, Ghent University]. http://lib.ugent.be/catalog/rug01:003015034

Vantyghem G, Boel V, Steeman M, de Corte W (2019a) Multi-material topology optimization involving simultaneous structural and thermal analyses. Struct Multidisc Optim 59(3):731–743. https://doi.org/10.1007/s00158-018-2095-z

Vantyghem G, de Corte W, Steeman M, Boel V (2019b) Density-based topology optimization for 3D-printable building structures. Struct Multidisc Optim 60(6):2391–2403. https://doi.org/10.1007/s00158-019-02330-7

Welty J, Rorrer GL, Foster DG (2014) Fundamentals of momentum, heat, and mass transfer. Wiley, New York

Xia Q, Wang MY (2008) Topology optimization of thermoelastic structures using level set method. Comput Mech 42(6):837–857. https://doi.org/10.1007/s00466-008-0287-x

Zheng B, Chang C, Gea H (2009) Topology optimization with design-dependent pressure loading. Struct Multidisc Optim 38(6):535–543. https://doi.org/10.1007/s00158-008-0317-5

Zhu X, Zhao C, Wang X, Zhou Y, Hu P, Ma Z-D (2019) Temperature-constrained topology optimization of thermo-mechanical coupled problems. Eng Optim 51(10):1687–1709. https://doi.org/10.1080/0305215X.2018.1554065

Zienkiewicz OC, Taylor RL, Zhu JZ (2013) The finite element method: its basis and fundamentals. Butterworth-Heinemann, Oxford

Acknowledgements

The authors thank Professor Krister Svanberg of the Royal Institute of Technology (KTH), Stockholm, for providing the MATLAB files for the MMA algorithm used in this study.

Funding

This research was supported by Ghent University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Replication of results

The included results can be replicated with the developed MATLAB code in the supplementary material and executed by a command of the following form:

top_tml_shc(L,h,t,z,Vf,rmin,pE,pk,pb)

where the variables refer to the corresponding parameters discussed in the paper.

For example, the optimization with the default parameters can be solved by entering the following command:

top_tml_shc(1200,400,10,10,0.4,3,3,3,3).

The MATLAB files mmasub.m and subsolv.m for using the MMA algorithm are freely available on http://www.smoptit.se/ under the GNU General Public License (GPLv3). One should reference them correctly in line 3 of the MATLAB code to carry out the optimization procedure. The latest version of the developed code is also available on https://github.com/tcooms/TopOpt-ThermoElastic.

Additional information

Responsible Editor: Jianbin Du

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Appendixes

Appendixes

1.1 Appendix 1: Verification sensitivity analysis

The verification of the analytical sensitivities obtained with the adjoint sensitivity analysis (Sect. 2.2.3) is performed based on the example of the MBB beam in Sect. 4. The analytical sensitivities of several arbitrary elements are compared with their corresponding numerical equivalent values, which are calculated with a central finite difference scheme (Cho and Choi 2005), as expressed in Eq. (53).

with \(c\) the structural compliance, \(\Delta {x}_{i}\) a small perturbation of the element density of \(\mathcal{O}\left({10}^{-8}\right)\) , and \({x}_{i}\) the relative density of element \(i\).

The relative (mean) difference between the analytical \({\text{d}}c/{\text{d}}{x}_{i}\) and numerical sensitivities \(\Delta c/2\Delta {x}_{i}\), denoted \(\overline{\delta c }\) here, is determined with Eq. (54), adapted from Tang et al. (2019).

with \(\left|{\overline{\text{d}c/{\text{d}}{\varvec{x}}}}\right|\) the mean value of the analytical sensitivities of all elements.

A comparison of the sensitivities is made on a coarser mesh of \(10\times 30\) elements for the sake of clarity. The sensitivities and corresponding differences of an arbitrary selection of 6 elements (indicated in Fig. 20) is provided in Table 5. The average iteration time considering the numerical sensitivities is 1.465 s, which is more than 200 times slower compared to 0.0064 s in case of the analytical sensitivities and clearly shows the advantage of the adjoint method for a high element count.

The results in Table 5 show insignificant differences between the analytical and numerical sensitivities, which confirms the accuracy of the sensitivities and justifies the use of the adjoint method in the proposed TO procedure. In addition, the verification results are visually presented in Fig. 21.

Note that using the mean value \(\left|\overline{{\text{d}c/{\text{d}}{\varvec{x}}}}\right|\) ensures a valid comparison for the large range of values, as in other formulations (Tang et al. 2019), the relative errors would become much larger in case of very small (but relatively very different) sensitivity values, e.g., elements 8, 168, 240 in Table 5.

1.2 Appendix 2: A 138-line MATLAB code for topology optimization with steady thermo-mechanical loads

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ooms, T., Vantyghem, G., Thienpont, T. et al. Compliance-based topology optimization of structural components subjected to thermo-mechanical loading. Struct Multidisc Optim 66, 126 (2023). https://doi.org/10.1007/s00158-023-03563-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-023-03563-3