Abstract

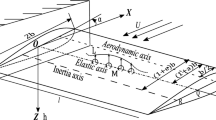

One of the current challenges in fluid topology optimization is to address these turbulent flows such that industrial or more realistic fluid flow devices can be designed. Therefore, there is a need for considering turbulence models in more efficient ways into the topology optimization framework. From the three possible approaches (DNS, LES, and RANS), the RANS approach is less computationally expensive. However, when considering the RANS models that have already been considered in fluid topology optimization (Spalart–Allmaras, k–ε, and k–ω models), they all include the additional complexity of having at least two more topology optimization coefficients (normally chosen in a “trial and error” approach). Thus, in this work, the topology optimization method is formulated based on the Wray–Agarwal model (“WA2018”), which combines modeling advantages of the k–ε model (“freestream” modeling) and the k–ω model (“near-wall” modeling), and relies on the solution of a single equation, also not requiring the computation of the wall distance. Therefore, this model requires the selection of less topology optimization parameters, while also being less computationally demanding in a topology optimization iterative framework than previously considered turbulence models. A discrete design variable configuration from the TOBS approach is adopted, which enforces a binary variables solution through a linearization, making it possible to achieve clearly defined topologies (solid–fluid) (i.e., with clearly defined boundaries during the topology optimization iterations), while also lessening the dependency of the material model penalization in the optimization process (Souza et al. 2021) and possibly reducing the number of topology optimization iterations until convergence. The traditional pseudo-density material model for topology optimization is adopted with a nodal (instead of element-wise) design variable, which enables the use of a PDE-based (Helmholtz) pseudo-density filter alongside the TOBS approach. The formulation is presented for axisymmetric flows with rotation around an axis (“2D swirl flow model”). Numerical examples are presented for some turbulent 2D swirl flow configurations in order to illustrate the approach.

Similar content being viewed by others

References

Alonso DH, de Sá LFN, Saenz JSR, Silva ECN (2018) Topology optimization applied to the design of 2d swirl flow devices. Struct Multidisc Optim 58(6):2341–2364. https://doi.org/10.1007/s00158-018-2078-0

Alonso DH, de Sá LFN, Saenz JSR, Silva ECN (2019) Topology optimization based on a two-dimensional swirl flow model of tesla-type pump devices. Comput Math Appl 77(9):2499–2533. https://doi.org/10.1016/j.camwa.2018.12.035

Alonso DH, Garcia Rodriguez LF, Silva ECN (2021) Flexible framework for fluid topology optimization with openfoam®and finite element-based high-level discrete adjoint method (fenics/dolfin-adjoint). Struct Multidisc Optim 1:32. https://doi.org/10.1007/s00158-021-03061-4

Andreasen CS, Gersborg AR, Sigmund O (2009) Topology optimization of microfluidic mixers. Int J Numer Meth Fluids 61:498–513. https://doi.org/10.1002/fld.1964

Arnold D, Brezzi F, Fortin M (1984) A stable finite element method for the stokes equations. Calcolo 21:337–344

Bardina JE, Huang PG, Coakley TJ (1997) Turbulence modeling validation, testing and development. Tech. rep, NASA Technical Memorandum, p 110446

Borrvall T, Petersson J (2003) Topology optimization of fluids in stokes flow. Int J Numer Meth Fluids 41(1):77–107. https://doi.org/10.1002/fld.426

Brezzi F, Fortin M (1991) Mixed and hybrid finite element methods. Springer, Berlin

Celik I (2003) RANS/LES/DES/DNS: the future prospects of turbulence modeling. J Fluids Eng 127(5):829–830. https://doi.org/10.1115/1.2033011

CFD group at Washington University in St Louis (2020) Wrayagarwalmodels. https://github.com/xuhanwustl/WrayAgarwalModels

Chen G, Xiong Q, Morris PJ, Paterson EG, Sergeev A, Wang Y (2014) Openfoam for computational fluid dynamics. Not AMS 61(4):354–363

COMSOL (2018) CFD Module User’s Guide, 5.4. COMSOL

De Chant LJ (2005) The venerable 1/7th power law turbulent velocity profile: a classical nonlinear boundary value problem solution and its relationship to stochastic processes. J Appl Math Comput Mech 161:463–474

Deardorff JW (1970) A numerical study of three-dimensional turbulent channel flow at large Reynolds numbers. J Fluid Mech 41(2):453–480

Dilgen CB, Dilgen SB, Fuhrman DR, Sigmund O, Lazarov BS (2018) Topology optimization of turbulent flows. Comput Methods Appl Mech Eng 331:363–393. https://doi.org/10.1016/j.cma.2017.11.029

Duan X, Li F, Qin X (2016) Topology optimization of incompressible Navier–Stokes problem by level set based adaptive mesh method. Comput Math Appl 72(4):1131–1141. https://doi.org/10.1016/j.camwa.2016.06.034

Engin T, Özdemir M (2009) Design, testing and two-dimensional flow modeling of a multiple-disk fan. Exp Thermal Fluid Sci 33(8):1180–1187. https://doi.org/10.1016/j.expthermflusci.2009.07.007

Evgrafov A (2004) Topology optimization of navier-stokes equations. In: Nordic MPS 2004. The Ninth Meeting of the Nordic Section of the Mathematical Programming Society, Linköping University Electronic Press, 014, pp 37–55

Farrell PE, Ham DA, Funke SW, Rognes ME (2013) Automated derivation of the adjoint of high-level transient finite element programs. SIAM J Sci Comput 35(4):C369–C393

Haftka RT, Gürdal Z (1991) Elements of structural optimization, vol 11. Springer, New York

Han X, Wray TJ, Fiola C, Agarwal RK (2015) Computation of flow in s ducts with Wray–Agarwal one-equation turbulence model. J Propul Power 31(5):1338–1349

Han X, Wray T, Agarwal RK (2017) Application of a new des model based on wray-agarwal turbulence model for simulation of wall-bounded flows with separation. In: 47th AIAA Fluid Dynamics Conference, p 3966

Han X, Rahman M, Agarwal RK (2018) Development and application of wall-distance-free Wray–Agarwal turbulence model (wa2018). In: 2018 AIAA Aerospace Sciences Meeting, p 0593

Hasund KES (2017) Topology optimization for unsteady flow with applications in biomedical flows. Master’s thesis, NTNU

Huang X, Xie Y (2007) Convergent and mesh-independent solutions for the bi-directional evolutionary structural optimization method. Finite Elements Anal Design 43(14):1039–1049. https://doi.org/10.1016/j.finel.2007.06.006

Hyun J, Wang S, Yang S (2014) Topology optimization of the shear thinning non-Newtonian fluidic systems for minimizing wall shear stress. Comput Math Appl 67(5):1154–1170. https://doi.org/10.1016/j.camwa.2013.12.013

Jensen KE, Szabo P, Okkels F (2012) Topology optimizatin of viscoelastic rectifiers. Appl Phys Lett 100(23):234102

Kontoleontos EA, Papoutsis-Kiachagias EM, Zymaris AS, Papadimitriou DI, Giannakoglou KC (2013) Adjoint-based constrained topology optimization for viscous flows, including heat transfer. Eng Optim 45(8):941–961. https://doi.org/10.1080/0305215X.2012.717074

Langtangen HP, Logg A (2016) Solving PDEs in Minutes - The FEniCS Tutorial Volume I. https://fenicsproject.org/book/

Lazarov BS, Sigmund O (2010) Filters in topology optimization based on Helmholtz-type differential equations. Int J Numer Meth Eng 86(6):765–781

Logg A, Mardal KA, Wells G (2012) Automated solution of differential equations by the finite element method: the FEniCS book, vol 84. Springer, New York

Mitusch S, Funke S, Dokken J (2019) Dolfin-adjoint 2018.1: automated adjoints for fenics and firedrake. J Open Source Softw 4(38):1292

Mortensen M, Langtangen HP, Wells GN (2011) A fenics-based programming framework for modeling turbulent flow by the Reynolds-averaged Navier–Stokes equations. Adv Water Res 34(9):1082–1101. https://doi.org/10.1016/j.advwatres.2011.02.013

Munson BR, Young DF, Okiishi TH (2009) Fundamentals of fluid mechanics, 6th edn. Wiley, Hoboken

Nørgaard S, Sigmund O, Lazarov B (2016) Topology optimization of unsteady flow problems using the lattice Boltzmann method. J Comput Phys 307:291–307. https://doi.org/10.1016/j.jcp.2015.12.023

Olesen LH, Okkels F, Bruus H (2006) A high-level programming-language implementation of topology optimization applied to steady-state Navier–Stokes flow. Int J Numer Meth Eng 65(7):975–1001

CFD Online (2020) Turbulence length scale. https://www.cfd-online.com/Wiki/Turbulence_length_scale

OpenFOAM Wiki (2014) Openfoam guide/the simple algorithm in openfoam. http://openfoamwiki.net/index.php/The_SIMPLE_algorithm_in_OpenFOAM

Orszag SA (1970) Analytical theories of turbulence. J Fluid Mech 41(2):363–386

Papoutsis-Kiachagias E, Kontoleontos E, Zymaris A, Papadimitriou D, Giannakoglou K (2011) Constrained topology optimization for laminar and turbulent flows, including heat transfer. CIRA, editor, EUROGEN, Evolutionary and Deterministic Methods for Design, Optimization and Control, Capua, Italy

Papoutsis-Kiachagias EM, Giannakoglou KC (2016) Continuous adjoint methods for turbulent flows, applied to shape and topology optimization: industrial applications. Arch Comput Methods Eng 23(2):255–299

Patankar SV (1980) Numerical heat transfer and fluid flow, 1st edn. McGraw-Hill, New York

Pingen G, Maute K (2010) Optimal design for non-Newtonian flows using a topology optimization approach. Comput Math Appl 59(7):2340–2350

Ramalingom D, Cocquet PH, Bastide A (2018) A new interpolation technique to deal with fluid–porous media interfaces for topology optimization of heat transfer. Comput Fluids 168:144–158. https://doi.org/10.1016/j.compfluid.2018.04.005

Reddy JN, Gartling DK (2010) The finite element method in heat transfer and fluid dynamics, 3rd edn. CRC Press, Boca Raton

Rey Ladino AF (2004) Numerical simulation of the flow field in a friction-type turbine (tesla turbine). Diploma thesis, Institute of Thermal Powerplants, Vienna University of Technology

Reynolds O (1895) IV on the dynamical theory of incompressible viscous fluids and the determination of the criterion. Philos Trans R Soc Lond (A) 86:123–164

Rice W (1991) Tesla turbomachinery

Romero J, Silva E (2014) A topology optimization approach applied to laminar flow machine rotor design. Comput Methods Appl Mech Eng 279(Supplement C):268–300. https://doi.org/10.1016/j.cma.2014.06.029

Romero JS, Silva ECN (2017) Non-Newtonian laminar flow machine rotor design by using topology optimization. Struct Multidisc Optim 55(5):1711–1732

Sá LF, Romero JS, Horikawa O, Silva ECN (2018) Topology optimization applied to the development of small scale pump. Struct Multidisc Optim 57(5):2045–2059. https://doi.org/10.1007/s00158-018-1966-7

Sá LFN, Amigo RCR, Novotny AA, Silva ECN (2016) Topological derivatives applied to fluid flow channel design optimization problems. Struct Multidisc Optim 54(2):249–264. https://doi.org/10.1007/s00158-016-1399-0

Saad T (2007) Turbulence modeling for beginners. https://www.cfd-online.com/W/images/3/31/Turbulence_Modeling_For_Beginners.pdf

Sato Y, Yaji K, Izui K, Yamada T, Nishiwaki S (2018) An optimum design method for a thermal-fluid device incorporating multiobjective topology optimization with an adaptive weighting scheme. J Mech Des 140(3):031402

Schwedes T, Ham DA, Funke SW, Piggott MD (2017) Mesh dependence in PDE-constrained optimisation—an application in tidal turbine array layouts, 1st edn. Springer, New York

Sivapuram R, Picelli R (2018) Topology optimization of binary structures using integer linear programming. Finite Elements Anal Design 139:49–61. https://doi.org/10.1016/j.finel.2017.10.006

Sivapuram R, Picelli R, Xie YM (2018) Topology optimization of binary microstructures involving various non-volume constraints. Comput Mater Sci 154:405–425. https://doi.org/10.1016/j.commatsci.2018.08.008

Smagorinsky J (1963) General circulation experiments with the primitive equations: I. The basic experiment. Monthly Weather Rev 91(3):99–164

Sokolowski J, Zochowski A (1999) On the topological derivative in shape optimization. SIAM J Control Optim 37(4):1251–1272

Song XG, Wang L, Baek SH, Park YC (2009) Multidisciplinary optimization of a butterfly valve. ISA Trans 48(3):370–377

Sonntag RE, Borgnakke C (2013) Fundamentals of thermodynamics, 8th edn. Wiley, Hoboken

Souza BC, Yamabe PVM, Sá LFN, Ranjbarzadeh S, Picelli R, Silva ECN (2021) Topology optimization of fluid flow by using integer linear programming. Struct Multidisc Optim 64:1221–1240

Spalart PRA, Allmaras S (1994) A one-equation turbulence model for aerodynamic flows. Cla Recherche Aérospatiale 1:5–21

Svanberg K (1987) The method of moving asymptotes-a new method for structural optimization. Int J Numer Methods Eng 24(2):359–373

Sá LF, Yamabe PV, Souza BC, Silva EC (2021) Topology optimization of turbulent rotating flows using Spalart–Allmaras model. Comput Methods Appl Mech Eng 373:113551. https://doi.org/10.1016/j.cma.2020.113551

Tesla N (1913a) Fluid propulsion. US Patent 1,061,142

Tesla N (1913b) Turbine. US 1(061):206

Tesla N (1921) Improved process of and apparatus for production of high vacua. GB Patent 179:043

Wächter A, Biegler LT (2006) On the implementation of an interior-point filter line-search algorithm for large-scale nonlinear programming. Math Progr 106(1):25–57

Weller HG, Tabor G, Jasak H, Fureby C (1998) A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput Phys 12(6):620–631

White FM (2011) Fluid mechanics, 7th edn. McGraw-Hill, New York

Wray T, Agarwal RK (2016) Application of the Wray–Agarwal model to compressible flows. In: 46th AIAA Fluid Dynamics Conference, p 3641

Wray TJ, Agarwal RK (2015) Low-Reynolds-number one-equation turbulence model based on k-\(\omega\) closure. AIAA J 53(8):2216–2227

Yoon GH (2016) Topology optimization for turbulent flow with Spalart–Allmaras model. Comput Methods Appl Mech Eng 303:288–311. https://doi.org/10.1016/j.cma.2016.01.014

Yoon GH (2020) Topology optimization method with finite elements based on the k-\(\varvec \varepsilon\) turbulence model. Comput Methods Appl Mech Eng 361:112784

Yu H (2015) Flow design optimization of blood pumps considering hemolysis. PhD thesis, Magdeburg, Universität, Diss., 2015

Zauderer E (1989) Partial differential equations of applied mathematics, 2nd edn. Wiley, Hoboken

Zhang X, Wray T, Agarwal RK (2016) Application of a new simple rotation and curvature correction to the wray-agarwal turbulence model. In: 46th AIAA Fluid Dynamics Conference, p 3475

Zhou S, Li Q (2008) A variationals level set method for the topology optimization of steady-state Navier–Stokes flow. J Comput Phys 227(24):10178–10195

Acknowledgements

This research was partly supported by CNPq (Brazilian Research Council), FAPERJ (Research Foundation of the State of Rio de Janeiro), and FAPESP (São Paulo Research Foundation). The authors thank the supporting institutions. The first author thanks the financial support of FAPESP under Grant 2017/27049-0. The third author thanks FAPESP under the Young Investigators Awards program under Grants 2018/05797-8 and 2019/01685-3, and FUSP (University of São Paulo Foundation) under Project Numbers 314139 and 314137. The fourth author thanks the financial support of CNPq (National Council for Research and Development) under Grant 302658/2018-1 and of FAPESP under Grant 2013/24434-0. The authors also acknowledge the support of the RCGI (Research Centre for Gas Innovation), hosted by the University of São Paulo (USP) and sponsored by FAPESP (2014/50279-4) and Shell Brazil.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest

Replication of results

The descriptions of the formulation, the numerical implementation, and the numerical results contain all necessary information for reproducing the results of this article.

Additional information

Responsible Editor: Ole Sigmund

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Comparison of sensitivities with finite differences

A comparison of the computed sensitivities (using dolfin-adjoint) with finite differences is presented in this appendix. The comparison is performed for the optimized topology for the rotating nozzle for turbulent flow under 10 L/min and 2500 rpm (Sect. 6.1), by considering the simulations for laminar (0.06 L/min and 25 rpm) and turbulent (10 L/min and 2500 rpm) flows. The set of points selected for comparison with finite differences in the computational domain is shown in Fig. 25. The comparison is performed for the same configurations considered for laminar and turbulent flows in Sect. 6.1. For \(\alpha = 1\) (fluid), the finite difference approximation is considered through the backward difference approximation: \(\frac{\text{{d}}J}{\text{{d}}\alpha } = \frac{J(\alpha ) - J(\alpha - {\Delta }\alpha )}{{\Delta }\alpha }\), where \(J = {\Phi }_{\text {rel}}\). For \(\alpha = 0\) (solid), the finite difference approximation is considered through forward difference approximation: \(\frac{\text{{d}}J}{\text{{d}}\alpha } = \frac{J(\alpha + {\Delta }\alpha ) - J(\alpha )}{{\Delta }\alpha }\). The computed sensitivities are shown in Fig. 26, for a step size of \(10^{-3}\). As can be seen, the computed sensitivities for this work (by using dolfin-adjoint) and finite differences are close to each other. For a better insight about the differences between the two sensitivities, Fig. 27 depicts the relative differences as defined below, which resulted small. The computed relative difference values may be viewed in sight of the fact that smaller objective function values may hinder the computation of finite differences due to computational errors, as observed in Yoon (2020); Haftka and Gürdal (1991). Furthermore, since a discrete algorithm (not continuous) is being considered in this work, this amount of difference does not seem to pose a problem.

where the subscript “p” indicates the “present work” approach (by using dolfin-adjoint) and “FD” indicates “Finite Differences.” The relative differences values are higher in the turbulent case due to the higher non-linearity of the fluid flow problem.

Relative differences for the cases shown in Fig. 26

Appendix B: 2D double pipe

The design of a 2D double pipe is performed in this Appendix, in order to show the Wray–Agarwal model (2018) being considered for topology optimization in a 2D case for a different initial guess configuration for the design variable. The topology optimization for this type of problem has been previously evaluated by Borrvall and Petersson (2003), for laminar Stokes flow. In this work, the inlets are set to be larger, which is reflected in setting the specified fluid volume fraction (f) as 50%, in order to make possible the formation of straight channels connecting the inlets to the outlets. Also, the outlet flow boundary condition is set as “stress free,” which is more generic (Hasund 2017) with respect to imposing fixed outlet velocity profiles as Borrvall and Petersson (2003). The design domain is shown in Fig. 28.

The mesh consists of 16,181 nodes and 32,000 elements (i.e., 100 horizontal and 80 vertical rectangular partitions of crossed triangular elements, see Fig. 29). The input parameters, geometric dimensions, and material model parameters that are considered for the design are shown in Table 5. The maximum inlet Reynolds number is 0.375 (laminar flow case) and \(2.8{\times }10^4\) (turbulent flow case). In order to consider a different configuration for the initial guess with respect to the other examples, the initial guess is chosen as shown in Fig. 30, where \(d = 37.5\) mm and \(r_c = 3.75\) mm. The TOBS approach is considered for \(\varepsilon _\text {relax} = 0.1\) and \(\beta _\text {flip\ limit} = 0.1\) (laminar flow case), and for \(\varepsilon _\text {relax} = 0.05\) and \(\beta _\text {flip\ limit} = 0.05\) (turbulent flow case).

The optimized topologies are shown in Fig. 31, where the maximum local Reynolds number is given as 0.46 (laminar flow case) and \(2.9{\times }10^4\) (turbulent flow case). As can be noticed, both optimized topologies are essentially different, where both channels join in the middle of the design domain for the laminar flow (similarly to the optimized results obtained by Borrvall and Petersson (2003)), but are kept separated for the turbulent flow. This difference in the optimized topologies shown in Fig. 31 can be viewed from the fact that the high inlet fluid flow velocity from the turbulent flow case does not allow creating a bend in the channel without dissipating significantly more energy, while the energy expended for that in the laminar flow case is minimal. This is also shown in the energy dissipation values from Table 6, where it can be seen that the optimized topologies perform better for their respective fluid flow regimes (43% better in the laminar flow case, and 46% better in the turbulent flow case).

Appendix C: 2D U-bend channel

The design of a 2D U-bend channel is performed in this Appendix, in order to show the Wray–Agarwal model (2018) being considered for topology optimization in a 2D case. This topology optimization problem has been previously evaluated by Dilgen et al. (2018), for the Spalart–Allmaras and k-\(\omega\) models considering the MMA (Method of Moving Asymptotes) algorithm. The 2D U-bend channel consists of an inlet and an outlet next to each other, with a “rod”-like structure in the middle of the channel that forces the optimized channel to go around it (see Fig. 32). The inlet and outlet zones, as well as the “rod”-like structure are kept as “non-optimizable.”

Since there is a “non-optimizable” zone inside the computational domain (see Fig. 32), when considering the Helmholtz pseudo-density filter, the filter is applied over the whole computational domain (\({\Omega }\)); however, the design variable value outside the design domain (\({\Omega }\setminus {\Omega }_\alpha\)) is enforced as the previous value (\(\alpha\)). Therefore, the variable \({\alpha }_{f,\text {new}}\) is used in the equations in function of the position (\({\varvec{s}}\)):

The local Reynolds number from Eq. (25) is redefined for this case, where the characteristic length is set as the width of the inlet (L, from Fig. 32) in the place of the external diameter (“\(2 r_{{ext}}\)”). As in the other numerical examples, the fluid is being considered as water.

The mesh consists of 92,431 nodes and 184,000 elements (i.e., 230 horizontal and 200 vertical rectangular partitions of crossed triangular elements, see Fig. 33). The input parameters, geometric dimensions, and material model parameters that are considered for the design are shown in Table 7. The maximum inlet Reynolds number is \(5.4{\times }10^4\). In this work, in order to facilitate convergence, the initial guess is given from the reference topology from Fig. 34. The specified fluid volume fraction (f) is set as 30%. The TOBS approach is considered for \(\varepsilon _\text {relax} = 0.2\) and \(\beta _\text {flip\ limit} = 0.001\).

The optimized topology is shown in Fig. 35, with the corresponding sensitivities’ distribution shown in Fig. 36, where the maximum local Reynolds number is given as \(2.7{\times }10^6\). As can be noticed, the optimized channel is expanded outwards with respect to the “rod”-like structure. Also, the optimized topology features a wider curve than the reference topology (Fig. 34). As a comparison, the optimized topology resulted in 35% less energy dissipation (\(1.10{\times }10^2\) W/m vs. \(1.70{\times }10^2\) W/m), and 11% (\(2.72{\times }10^{-2}\) m vs. \(3.04{\times }10^{-2}\) m) less head loss than the reference topology.

The simulation of the optimized design is shown in Fig. 37. From it, it can be noticed that the small “bumps” of the optimized topology near the inlet and outlet of the design domain do not significantly change the velocity field of the fluid flow simulation, meaning that their contribution to the energy dissipation should be small. Also, the curve in the optimized channel reduces the bending necessary for the fluid to head towards the outlet, reducing energy dissipation and head loss.

Figure 38 shows a comparison of streamlines between the simulations for the modeled solid material, for the Helmholtz filter (\(r_H =\) 1.0 mm) and for the post-processed topology. As can be noticed, some differences arise between the simulations. First, the streamlines for the modeled solid simulation show an acceleration of the fluid flow after the curve, which is not present in the simulation of the post-processed topology. This effect can also be observed in Dilgen et al. (2018) (Figs. 10c and 14b of Dilgen et al. (2018)). This seems to be a drawback of the modeled material used in fluid topology optimization (inverse permeability), since this modeled material intrinsically implies that there will be fluid flow inside the solid material, even at extremely small values, which may possibly lead to small changes in the characteristics of the solid boundaries and may affect the turbulent flow modeling. When considering the Helmholtz filter, the boundaries are blurred, which has the effect of leading the topology optimization to focus on the main flow, giving less emphasis to local effects that may possibly destabilize the fluid flow (such as some specific inclusions in the middle of the channel) or lead the topology optimization to a relatively worse local minimum.

Rights and permissions

About this article

Cite this article

Alonso, D.H., Romero Saenz, J.S., Picelli, R. et al. Topology optimization method based on the Wray–Agarwal turbulence model. Struct Multidisc Optim 65, 82 (2022). https://doi.org/10.1007/s00158-021-03106-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-021-03106-8