Abstract

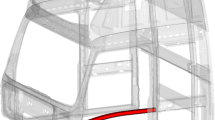

The optimization of the crashworthiness and lightweight design of S-rail extracted from the frontal body in white was studied in this paper. A physical test was conducted to verify the validity of S-rail model and then an implicit parameterization model was built based on the S-rail model using the software SFE-CONCEPT. Based on the implicit parameterization modeling, a steel-aluminum S-rail was designed to reduce the peak collision force (PCF) and increase the specific energy absorption (SEA) under the condition that the total weight (M) of S-rail does not increase. L16 (45) Taguchi array was used to collect sample points which will be prepared for the optimization design. The experimental results were analyzed through grey relational analysis (GRA) coupled with grey entropy measurement method. The multi-objective optimization was then converted into a single objective optimization problem based on the grey relational grade. The optimal combination of design parameters for S-rail was obtained using the proposed method. Meanwhile, a comparison was presented between the proposed method and other extensively used methods (i.e. NSGA-II, MOPSO, and ASA), and the proposed method reduces the PCF and M to 26.81% and 46.01% respectively, and increases the corresponding SEA by 176.06%. Moreover the computational cost can be reduced by 143.5% at least when compared with other extensively used methods. Therefore, the hybrid method can efficiently improve the crashworthiness and reduce the computational cost during the design process of S-rail.

Similar content being viewed by others

References

Amit S, Vinod Y (2011) Optimization of cut quality characteristics during Nd: YAG laser straight cutting of Ni-based superalloy thin sheet using grey relational analysis with entropy measurement. Mater Manuf Process 26(12):1522–1529

Beik V, Fard M, Jazar R (2016) Crashworthiness of tapered thin-walled s-shaped structures. Thin-Walled Struct 102:139–147

Chen S, Wang D (2011) Optimization of vehicle ride comfort and controllability using Grey relational analysis. J Grey Syst 23(4):369–380

Datta S, Nandi G, Bandyopadhyay A (2009) Application of entropy measurement technique in grey based Taguchi method for solution of correlated multiple response optimization problems: a case study in welding. J Manuf Syst 28(2):55–63

Deng JL (1982) Control problems of grey systems. Syst Control Lett 1(5):288–294

Deng JL (1989) Introduction to grey system theory. J Grey Syst 1(1):1–24

Duan L, Sun G, Cui J et al (2016) Crashworthiness design of vehicle structure with tailor rolled blank. Struct Multidiscip Optim 53(2):321–338

Duan L, Xiao N C, Hu Z et al. (2017) An efficient lightweight design strategy for body-in-white based on implicit parameterization technique. Struct Multidiscip Optim 55(5):1927–1943

Duddeck F, Zimmer H (2012) New achievements on implicit parameterisation techniques for combined shape and topology optimization for crashworthiness based on SFE concept

Elmarakbi A, Long YX, Macintyre J (2013) Crash analysis and energy absorption characteristics of s-shaped longitudinal members. Thin-Walled Struct 68(10):65–74

Fang J, Gao Y, Sun G, Xu C, Li Q (2015) Multiobjective robust design optimization of fatigue life for a truck cab. Reliab Eng Syst Saf 135(135):1–8

Fang J, Sun G, Qiu N, Kim NH, Li Q (2017) On design optimization for structural crashworthiness and its state of the art. Struct Multidiscip Optim 55(3):1091–1119

Gedikli H (2013) Numerical investigation of axial crushing behavior of a tailor welded tube. Mater Des 44:587–595

Georgios K, Dimitrios S (2009) Multi-disciplinary design optimization exploiting the efficiency of ANSA-LSOPT-META coupling. In: Proceedings 7th European LS-DYNA conference, Salzburg

Hilmann J, Paas M, Haenschke A et al (2007) Automatic concept model generation for optimization and robust design of passenger cars. Adv Eng Softw 38(11–12):795–801

Hosseini-Tehrani P, Nikahd M (2006) Two materials s-frame representation for improving crashworthiness and lightening. Thin-Walled Struct 44(4):407–414

Huh H, Kim SB, Song JH, Lim JH (2008) Dynamic tensile characteristics of TRIP-type and DP-type steel sheets for an auto-body. Int J Mech Sci 50(5):918–931

Hunkeler S, Duddeck F, Rayamajhi M et al (2013) Shape optimisation for crashworthiness followed by a robustness analysis with respect to shape variables. Struct Multidiscip Optim 48(2):367–378

Kashani MH, Alavijeh HS, Akbarshahi H, et al (2013) Bitubular square tubes with different arrangements under quasi-static axial compression loading. Materials & Design, 51(Complete), 1095–1103.

Khalkhali A (2015) Best compromising crashworthiness design of automotive S-rail using TOPSIS and modified NSGA-II. J Cent South Univ 22(1):121–133

Khalkhali A, Mostafapour M, Tabatabaie SM et al (2016) Multi-objective crashworthiness optimization of perforated square tubes using modified NSGA-II and MOPSO. Struct Multidiscip Optim 54(1):45–61

Kim HS (2002) New extruded multi-cell aluminum profile for maximum crash energy absorption and weight efficiency. Thin-Walled Struct 40(4):311–327

Kim HS, Wierzbicki T (2001) Effect of the cross-sectional shape of hat-type cross-section on crash resistance of an “S”-frame. Thin-Walled Struct 39(7):535–554

Kohar CP, Zhumagulov A, Brahme A et al (2016) Development of high crush efficient, extrudable aluminum front rails for vehicle lightweighting. Int J Impact Eng 95:17–34

Langseth M, Hopperstad OS (1996) Static and dynamic axial crushing of square thin-walled aluminum extrusions. Int J Impact Eng 18(7):949–968

Liu S, Li Y, Liao Y, Guo Z (2014) Structural optimization of the cross-beam of a gantry machine tool based on grey relational analysis. Struct Multidiscip Optim 50(2):297–311

Madasamy C,Faruque O,Tyan T (2002) Experimental Study on the Crash Performance of Aluminum and Steel Rails. ASME International Mechanical Engineering Congress & Exposition November 17–22, 2002, New Orleans

Nalbant M, Gökkaya H, Sur G (2007) Application of Taguchi method in the optimization of cutting parameters for surface roughness in turning. Mater Des 28(4):1379–1385

Parisa HT, Mossa N (2006) Two materials S-frame representation for improving crash worthiness and lightening. Thin-Walled Struct 44(4):407–414

Prasanna J, Karunamoorthy L, Raman MV, Prashanth S, Chordia DR (2014) Optimization of process parameters of small hole dry drilling in ti–6al–4v using Taguchi and grey relational analysis. Measurement 48(1):346–354

Reddy S, Abbasi M, Fard M (2015) Multi-cornered thin-walled sheet metal members for enhanced crashworthiness and occupant protection. Thin-Walled Struct 94:56–66

Redhe M, Giger M, Nilsson L (2004) An investigation of structural optimization in crashworthiness design using a stochastic approach. Struct Multidiscip Optim 27(6):446–459

Sathiya P, Jaleel MYA, Katherasan D, Shanmugarajan B (2011) Optimization of laser butt welding parameters based on the orthogonal array with fuzzy logic and desirability approach. Struct Multidiscip Optim 44(4):499–515

Schubert E, Klassen M, Zerner I et al (2001) Lightweight structures produced by laser beam joining for future applications in automobile and aerospace industry. J Mater Process Technol 115(1):2–8

Shi Y, Zhu P, Shen L, Lin Z (2007) Lightweight design of automotive front side rails with TWB concept. Thin-Walled Struct 45(1):8–14

Siddiquee AN, Khan ZA, Mallick Z (2010) Grey relational analysis coupled with principal component analysis for optimization design of the process parameters in in-feed centreless cylindrical grinding. Int J Adv Manuf Technol 46(9–12):983–992

Smerd R, Winkler S, Salisbury C et al (2005) High strain rate tensile testing of automotive aluminum alloy sheet. Int J Impact Eng 32(1):541–560

Standard SAE (1995) J211: Instrumentation for Impact Test. Technical Report, Safety Test Instrumentation Stds Comm

Tai YS, Huang MY, Hu HT (2010) Axial compression and energy absorption characteristics of high-strength thin-walled cylinders under impact load. Theor Appl Fract Mech 53(1):1–8

Varun A, Venkaiah N (2015) Simultaneous optimization of WEDM responses using grey relational analysis coupled with genetic algorithm while machining EN 353. Int J Adv Manuf Technol 76(1–4):675–690

Vinayagar K, Kumar AS (2017) Multi-response optimization of crashworthiness parameters of bi-tubular structures. Steel And Composite Structures 23:31–40

Wang P, Meng P, Zhai JY et al (2013) A hybrid method using experiment design and grey relational analysis for multiple criteria decision making problems. Knowl-Based Syst 53(9):100–107

Wen KL, Chang TC, You ML (1998) The grey entropy and its application in weighting analysis. IEEE International Conference on Systems, Man, and Cybernetics 2:1842–1844

Xie S, Liang X, Zhou H, Li J (2015) Crashworthiness optimisation of the front-end structure of the lead car of a high-speed train. Struct Multidiscip Optim 53(2):1–9

Xu F, Sun G, Li G et al (2013) Crashworthiness design of multi-component tailor-welded blank (TWB) structures. Struct Multidiscip Optim 48(3):653–667

Zhou Y, Lan F, Chen J (2011) Crashworthiness research on S-shaped front rails made of steel-aluminum hybrid materials. Thin-Walled Struct 49(2):291–297

Zimmer H (2010) SFE-CONCEPT reference manual v4.2. SFE-GmbH, Berlin, Germany

Acknowledgements

This research work was support by the national key research and development project (2016YFB0101601). The author would like to express their appreciations for the above fund supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, K., Wang, D. Optimizing the design of automotive S-rail using grey relational analysis coupled with grey entropy measurement to improve crashworthiness. Struct Multidisc Optim 56, 1539–1553 (2017). https://doi.org/10.1007/s00158-017-1728-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-017-1728-y