Abstract

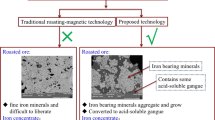

A new method of solid-phase reduction magnetic separation with pyrite as a reducing agent was proposed in order to realize resource utilization of high iron bauxite residue while reducing environmental harm. FeS2 powder and high iron bauxite residue powder were uniformly blended and roasted in a closed environment. A magnetic separator was utilized to separate the magnetic iron concentrate at 2400 GS, and the recovery rates were calculated. Experimental results show that the best iron recovery was 91.5% at 1:6 roasted bauxite: residue at 800℃ for 2 h. The recovery of Fe can be improved by reducing high iron bauxite residue with pyrite, and iron in both pyrite and high iron bauxite residue can be recovered simultaneously, alleviating the pressure of iron ore resources and improving its utilization value.

Similar content being viewed by others

References

Agrawal S, Dhawan N (2020) Investigation of carbothermic microwave reduction followed by acid leaching for recovery of iron and aluminum values from Indian red mud. Miner Eng 159:106653

Ambikadevi VR, Lalithambika M (2000) Effect of organic acids on ferric iron removal from iron-stained kaolinite. Appl Clay Ence 16:133–145

Bi SW, Yu HY. Alumina production process (2006) Beijing: Chemical Industry Press, pp 9–11.

Chen RW (2013) Composition analysis and characterization of red mud, an industrial solid waste from alumina smelting. Ceram Sci Art 4:17–19

Chen LY, Jiang W, Li FS et al (2005) Preparation of magnetic nano Fe3O4/SiO2 composite particles by liquid deposition. Mech Eng Mater 29(4):4

Deng BN, Li GH, Luo J et al (2017) Enrichment of Sc2O3 and TiO2 from bauxite ore residues. J Hazard Mater 331:71–80

He AP, Hu ZL, Cao DG et al (2014) Comprehensive utilization of red mud remaining in alumina production. Adv Mater Res 881–883:663–666

Hu W, Xiong DH (2010) Study on iron recovery from tailings and tailings by high-intensity magnetic separation gravity separation combined process. Nonferrous Met Sci Eng 1(3):52–54

Ke WS, Zhang XC, Zhu F et al (2021) Appropriate human intervention stimulates the development of microbial communities and soil formation at a long-term weathered bauxite residue disposal area. J Hazard Mater 405:124689

Kumar V, Ahlawat DS, Islam SA et al (2021) Ce doping induced modifications in structural, electrical and magnetic behaviour of hematite nanoparticles. Mater Sci Eng B 272(10):115327

Li YR, Wang J, Wang XJ et al (2011) Feasibility study of iron mineral separation from red mud by high gradient superconducting magnetic separation. Physica C 471(3–4):91–96

Lin M, Yang B, Lin H et al (2021) Catalytic effects of red mud and acidithiobacillus ferrooxidans on biodissolution of pyrite. IOP Conf Ser 768(1):012019

Liu PK, Jiang LY, Yang XH (2017) Experimental study on iron enrichment performance of red mud by total gravity separation. Light Metals 6:22–27

Liu X, Han YX, He FY et al (2021) Characteristic, hazard and iron recovery technology of red mud—a critical review. J Hazard Mater 420:126542

Pepper RA, Couperthwaite SJ, Millar GJ (2018) Value adding red mud waste: impact of bauxite residue composition upon fluoride removal performance of synthesised akaganeite sorbents. J Environ Chem Eng 6(2).

Samal S (2021) Utilization of red mud as a source for metal ions—a review. Materials 14(9):2211

Samouhos M, Taxiarchou M, Pilatos G et al (2017) Controlled reduction of red mud by H2 followed by magnetic separation. Miner Eng 105:36–43

Vaish G, Kripal R, Kumar L (2021) Comprehensive study of magnetic and optoelectronic properties of MgFe2O4–TiO2 nanocomposites. Mater Chem Phys 271:124911

Wang H, Wang JS, Liu J et al (2013) Experimental study on comprehensive utilization of high iron red mud based on Direct Reduction melting. Light Metals 1:19–22

Wang L, Sun N, Tang HH et al (2019) A review on comprehensive utilization of red mud and prospect analysis. Minerals 9(6):9060362

Xue SG, Liu Z, Fan JR et al (2022) Insights into variations on dissolved organic matter of bauxite residue during soil-formation processes following 2-year column simulation. Environ Pollut 292:118326

Xu SA, Shao YH, Xiong SQ (2015) Test on recovery of fine iron ore from red mud by hydrophobic agglomeration magnetic separation. Comprehen Util Miner 6:62–66

Yan YT, Li SR, Jia BJ et al (2012) Characteristics and statistical analysis of pyrite composition typomorphic characteristics of different genetic types of gold deposits in China. Earth Sci Front 19(4):214–226

Yang Y, Wang XW, Wang MY (2015) Recovery of iron from red mud by selective leach with oxalic acid. Hydrometallurgy 157:239–245

Yu ZL, Shi ZX, Chen YM et al (2012) Red-mud treatment using oxalic acid by UV irradiation assistance. Trans Nonferrous Met Soc China 22(2):456–460

Zhang LX, Gao YQ, Huang JH et al (2020) Research progress on comprehensive utilization of red mud resources. Silicate Bulletin 39(01):6

Funding

Funding was provided by the National Natural Science Foundation of China (Nos. U1710257, 51874078, U1202274), the State Key Laboratory of Pressure Hydrometallurgical Technology of Associated Nonferrous Metal Resources (YY2016006), the Fundamental Research Funds for the Central Universities of China (N2025038), and the Shenyang Science and Technology Project (17-500-8-01, Z18-5-022).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fu, H., Lv, G., Zhang, Ta. et al. Study on Iron Extraction from High Iron Bauxite Residue by Pyrite Reduction. Bull Environ Contam Toxicol 109, 149–154 (2022). https://doi.org/10.1007/s00128-022-03520-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00128-022-03520-8