Abstract

The trend of increasing demand for wood raw material is becoming of great global concern. Fast-growing plantations, such as those of Paulownia, are being established in different parts of the world, as a viable alternative to quickly produce quality wood at competitive costs. The presence and proportion of juvenile wood directly influences the capacity and possibilities of industrial transformation for sawn timber, veneer or plywood for furniture, construction or packaging purposes. The objective of the research is to analyze the radial variation of physical and anatomical characteristics of Paulownia elongata x fortune hybrid Cotevisa 2 wood from fast-growing plantations. A sample of 14 trees from a seven-year-old plantation established in Valencia (Spain) with a planting frame of 4 m × 4 m was used. Although there is no data from subsequent rings to the 6th, the obtained results indicate that from the 5th year of growth, the wood of Paulownia elongata x fortunei Cotevisa 2 could stabilize in some key parameters such as the radial growth of the rings, the structure and proportion of the vessels, the structure of the cell wall, the density of the material and the behavior in terms of dimensional stability in the drying process. Thus, for practical purposes, we can indicate that the transition from juvenile wood to mature wood can begin from the 5th year of growth. Enlarging the rotation in few years reduces significantly the presence of juvenile wood and contributes to improve the roundwood quality for added-value solid wood products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Various forecasts have predicted a steady increase in the global demand for fibrous materials in the wood-based industry until at least 2050 (Sikkema et al. 2021; Kircher 2022). On the other hand, the natural forests have declined as wood supply over the years, while plantation forests have increased steadily and they will predominate in large parts of the world as future sustainable source of wood (FAO 2022). For this, there is a rapidly growing interest, worldwide, in plantations of fast-growing wood species that can be used for production of industrial wood (McEwan et al. 2020), for conservation of natural ecosystems (Pirard et al. 2016) as well as for carbon fixation (Bredemeier et al. 2015). As one of the fastest-growing tree species in the world, the genus Paulownia Siebold & Zuccarini, has attracted enormous interest in recent years (Jakubowski 2022).

The genus Paulownia, belonging to the family Paulowniaceae and indigenous to China and East Asia, consists of nine species (Hassler 2022); the most important used and studied species are Paulownia elongata S. Y. Hu, Paulownia fortunei (Seem.) Hemsl. and Paulownia tomentosa (Thunb.) Steud. (Zhao-Hua et al. 1986; Jakubowski 2022). Different hybrids have also been developed, such as Paulownia hybrid Cotevisa 2 produced in Spain, which is the result of the cross between Paulownia elongata x Paulownia fortunei (Esteves et al. 2022; Jakubowski 2022).

Paulownia species or hybrids have been introduced in North America, Australia, Japan, Iran, Kyrgyzstan and Kenya (Jakubowski 2022). In Europe, its presence is documented in Spain, Portugal, Hungary, Turkey, Croatia, Italy, Serbia, Romania, Northern Ireland, Czech Republic, and Ukraine (Jakubowski 2022). Paulownia is a deciduous tree capable of achieving very high growth rates under favorable conditions (Zhao-Hua et al. 1986; Flynn and Holder 2001).

The wood of Paulownia is defined as straight grained, with gloss after being planed, light, soft, inodorous, and with few knots (Zhao-Hua et al. 1986). Paulownia wood is traditionally used for a variety of applications, such as furniture, construction, musical instrument, ship building, aircraft, packing boxes, cabinet making, molding, kitchen items and paper (Zhao-Hua et al. 1986; Akyildiz and Kol 2010; Jakubowski 2022). Paulownia wood also performs well in the production of plywood, LVL or blockboards, which act as a core layer between veneers and as an ingredient for the production of lightweight particleboards (Bee et al. 2005; Jakubowski 2022). Nowadays, Paulownia plantations oriented towards chip production for biomass or wood-based panels are gaining in popularity (Fernández-Puratich et al. 2017; Esteves et al. 2022). There is currently a lot of research being conducted that is aimed at furthering the use of Paulownia wood in the production of wood plastics and composites and in the production of biopolymers (Jakubowski 2022).

The radial cross-section of a stem can be divided into three zones: juvenile wood (JW), transition wood and mature wood; but most of the time only juvenile wood and mature wood are considered (Alteyrac et al. 2006). The juvenile wood is the secondary xylem formed during the early life of a tree and all trees have juvenile wood, but it has little significance when the timber supply is primarily old-growth trees grown in old natural forest ecosystems (Kretschmann et al. 1993). In these old trees, the juvenile wood core is small because early growth is suppressed by competition from surrounding trees and thus, the juvenile wood proportion in the total volume is small (Tsoumis 2009; Ruano and Hermoso 2021). Otherwise, fast-growing trees that reach sawn timber size are harvested at an early age on short rotations in plantations and they contain a bigger core of juvenile wood in comparison with harvested timber from natural forests (Dowse and Wessels 2013; Nawrot et al. 2014; Wessels et al. 2014; Hermoso et al. 2016; Boruszewski et al. 2017).

It is well known that juvenile wood characteristics contribute to undesirable solid wood properties (sawn timber, veneer and wood-based panels) (Zobel 1984), due to its low bending strength and dimensional instability upon drying (Moore and Cown 2017). Juvenile wood often has different properties compared to mature wood (Barbour 2004). The age of transition between juvenile and mature wood has been difficult to determine because transition is gradual and not abrupt and the estimate of the transition to mature wood may vary depending on the property used (Alteyrac et al. 2006; Clark et al. 2006; Marbun et al. 2020). The duration of the period when juvenile wood is produced, the rate of transition from juvenile wood to mature wood, and the differences in properties between juvenile wood and mature wood differ among species (Bao et al. 2001) and are all important in determining the suitability of wood for specific end uses (Zobel and Sprague 1998).

Differences in chemical, physical, anatomical, and visual characteristics have all been reported for various species, and the importance of each depends on the wood product to be manufactured. So, pith-to-cambium variation in anatomical wood traits, such as ring width and latewood proportion, differences in cell wall thickness, microfibril angle and fiber length are frequently described in terms of juvenile and mature wood zones and are used to estimate transition age (Burdon et al. 2004; Lachenbruch et al. 2011; Darmawan et al. 2015; Moore and Cown 2017), but also different physical properties related to dimensional stability of sawn timber, such as density, longitudinal shrinkage, or anisotropic shrinkage coefficient, have been studied for different species (Harris 1977; Oliver-Villanueva and Becker 1993; Pliura et al. 2005; Zhang et al. 2021). One of the most serious problems in drying and utilization of young plantation timber is warp in the form of twist, crook and bow (Oliver-Villanueva and Becker 1993; Kliger 2001; Johansson and Kliger 2002; Moore and Cown 2017).

In summary, in fast rotation timbers, anatomical parameters like fiber length, microfibrillar angle, vessel diameter/percentage and ring width appear to be the best indicators of age demarcation between juvenile and mature wood, although maturation age often varies among the properties (Bhat et al. 2001). However, for solid wood uses like sawn timber for construction or furniture or rotary veneer for plywood or LVL, or other ultra-light wood-based panels, other physical properties are of key relevance for drying and mechanical transformation processes, like dimensional stability, especially longitudinal shrinkage and anisotropic coefficient, i.e. relation between radial and tangential shrinkage (Oliver-Villanueva and Becker 1993; Geimer et al. 1997; Ab Latib et al. 2020). Therefore, this research combines the analysis of morphological and anatomical characteristics and physical properties of Paulownia wood produced in very short rotations in intensive plantations with optimal growth conditions to obtain results that allow us to establish the limit between juvenile and mature wood in order to optimize their industrial transformation processes, their use as value-added solid wood products in furniture, construction and packaging, and the production of biomass and cellulose.

Bearing in mind that the new Paulownia plantations established in different world regions have as their main objective the production of high quality wood in very short rotations for use in added-value products, the objective of the research is to reveal radial variations in wood anatomical structure and physical properties, and to determine the beginning of the transition between juvenile and mature wood of Paulownia hybrid Cotevisa 2, as a clone widely used in the Mediterranean area in fast-growing plantations.

2 Materials and methods

2.1 Paulownia elongata x Paulownia fortunei hybrid Cotevisa 2 fast-growing plantation

For the election of a representative experimental plot of the recently established plantations of Paulownia in the Mediterranean area, a plantation of 10 hectares of almost 7 years old in Navarrés (Valencia, Spain, 39º 6′ 5″ N, 0º 41′ 36″ W) at an average altitude of 276 m.o.s.l. was selected. In this location, as an example of a Mediterranean climate, summers are short, hot and mostly clear. Winters are long, cold, windy and partly cloudy and it is dry throughout the year, with an average rainfall of less than 400 mm, with very dry summer months. During the course of the year, the temperature generally varies from 3 to 33 °C, with an average of 20 °C.

The plantation was established on land previously used for agriculture on predominantly calcareous soil, which allows localized drip irrigation and fertilization, favoring the fast growth regime of the young trees. Weed competition due to mechanized tillage has also been regularly eliminated. It is, therefore, an intensive crop for a forest plantation, just as this type of plantations have been established during the last years in Mediterranean areas as an alternative to traditional, less profitable agriculture. For the plantation, the Cotevisa 2 clone was used, which is a hybrid of Paulownia elongata x Paulownia fortunei widely used in different regions of the European Mediterranean area (Zuazo et al. 2013). The planting frame has been of 4 m × 4 m with a stocking density of 625 trees/ha. The silvicultural treatments were an initial pruning to form the crown the first year and quality prunings in the following years, avoiding removing more than 25% of the living crown on its lower branches.

An inventory of the breast height diameter (BHD) and the height (H) of the entire regular and even-aged plantation was carried out for the selection of the representative trees. Firstly, selecting the 40 most representative trees, straight with uniform crowns and without visible defects following the indications of Hapla and Saborowski (1987) and from these, 14 individuals were randomly chosen to be felled.

2.2 Wood sample preparation

Discs of approximately 15 cm thickness were cut from the trunk at BH of each felled tree (Fig. 1a and Fig. 2a, b). Maximum and minimum diameter (dmax and dmin) without the bark, maximum and minimum radius (rmax and rmin) without the bark, pith diameter and bark thickness were measured on each disc.

Paulownia hybrid Cotevisa 2 wood. a Sample of disc used for morphological characteristics. b Half disc after extraction of core board by the representative diameter. c Dimension of core board used for evaluation of the physical properties of wood. d Sample of physical properties core board before the extraction of individual samples from each ring. e Individual samples of each ring obtained from the physical properties core board and used for evaluation of the physical properties of wood

Schematic of sample preparation used for the analysis of Paulownia hybrid Cotevisa 2 wood. a Position of disc in the trunk. b Representative diameter for the extraction of the core board. c Extraction of the core board used for the wood analysis. d Dimension of the individual samples of wood used for determination of the physical properties. e Dimension of the complete core board of wood used for the macroscopic anatomical analysis

Ovality (Ov) and eccentricity (Ec) of each disc were also calculated as follows:

After seasoning to final moisture content of 12%, transverse sections of all discs were sanded and then the representative diameter of each disc at 22.5º clockwise from the maximum diameter was obtained according to Siostrzonek (1958) (Figs. 1b and 2b).

Two central cores of 20 mm wide were obtained on the representative diameter in each disk (Fig. 2b, c): one diametrical core of 80 mm thickness for physical properties analysis (Figs. 1c, d and 2c, d) and another diametrical core of 20 mm thickness anatomical analysis (Figs. 2c, e and 3a).

Sample of Paulownia hybrid Cotevisa 2 wood used for the macroscopic anatomical analysis. a Complete core board with the area used for the macroscopic anatomical analysis. b Magnified image (6X) showing a complete annual growth ring. c Magnified image (30×) with detail of earlywood showing the typology of vessels. d Magnified image (30×) with detail of latewood showing the typology of vessels. Solitary vessels (S) and radial multiple vessels (R)

2.3 Macroscopic anatomical analysis

The complete anatomical core board of 20 mm thickness was used for evaluation of the macroscopic wood structure (Figs. 2c and 3a). Annual ring width was measured using an electronic caliper (0.01 mm of resolution) in each complete core in both opposite radii (Figs. 2e and 3a). The total number of vessels and vessel density (vessels/mm2) were measured in each ring in the central area of 10 mm thickness in both opposite radii of the core (Fig. 3a, b). The vessels were classified in two categories to determine their typology: solitary vessels (Fig. 3c-S and d-S) and radial multiple vessels (2, 3 or more vessels) (Fig. 3c-R and d-R). The vessel number and typology were determined using a Leica S9i stereomicroscope, which is equipped with a camera connected to the computer software Leica Application Suite.

2.4 Physical properties

Each physical properties core board of 80 mm thickness (Figs. 1c, d and 2c, d) was cut in annual ring boundaries of six rings in both representative opposite radii to obtain the individual samples used for the evaluation of the wood physical properties (Figs. 1e and 2d). The oven-dry density (Do), basic density (Db), tangential, radial, longitudinal (S(R, T, L)) and volumetric shrinkages (β(V)), anisotropic coefficient (ST/SR), fiber saturation point (FSP), percentage of the cell wall (VC), porosity (VH), and maximum moisture content (Mmax) of each individual sample were measured.

The oven–dry density (Do) was calculated as follows:

where Mo is the oven-dry mass (g) and Vo is the oven-dry volume (cm3) of the sample, respectively.

The basic density (Db) was determined by gravimetric methods (Bowyer et al 2005) as follows:

where MO is the oven-dry mass (g) and Vs is saturated volume (cm3) of the sample.

The volumetric shrinkage β(V) was determined as follows:

where Vs is saturated volume (cm3) and VO is the oven-dry volume (cm3) of the sample.

Radial (SR), tangential (ST) and longitudinal (SL) shrinkages were determined as follows:

where LS is the length in saturated conditions (mm) and Lo is the length in oven-dry conditions (mm) of the sample in radial, tangential or longitudinal directions, respectively. The length was measured using an electronic caliper with a resolution of 0.01 mm.

Fiber saturation point (FSP) was calculated by the following equation:

where β(V) is volumetric shrinkage (%) and (Db) is basic density (g/cm3).

The percentage of the cell wall (VC) and porosity (VH) were calculated by the following equations:

and

where VC is the percentage of the cell wall (%), Do is oven density 100 (g/cm3), DC is oven-dry density of the wall cell (1.5 g/cm3) and VH is the percentage of porosity (%).

The maximum moisture content (MMC) was calculated by the following equation:

2.5 Statistical analysis

For the data analysis, analysis of variance (ANOVA) was performed using Statgraphics plus software. For each parameter, a simple factorial ANOVA was carried out using the year ring as the main factor. Tukey multiple comparison test was used for each ANOVA to determine the significance of any differences between the different rings (p < 0.05).

3 Results and discussion

3.1 Morphological characteristics

The sample trees of Paulownia hybrid Cotevisa 2 at breast height have an average diameter of 29.6 cm, with a minimum of 22.4 cm and a maximum of 35.1 cm without the bark. The average annual diametric growth rate is of almost 40 mm/year (Table 1). These results are consistent with the growth data achieved by different Paulownia species in their natural distribution area for 10-year-old trees (Zhao-Hua et al. 1986). In the case of Paulownia elongata trees, the diameters reached are 18 cm for 5-year-old trees and 40 cm for 10-year-old trees (Zhao-Hua et al. 1986) and from 41 to 49 for 13-year-old trees (Bao et al. 2001). For the other parental species of this hybrid, Paulownia fortunei, the average diameters reached are 15 cm for 5-year-old trees from plantations in China (Zhao-Hua et al. 1986) and average diameters greater than 40 cm for 6-year-old trees from plantations in Iran (Kiaei 2013). The annual diametric growth rate of almost 40 mm/year is comparable with that of Paulownia elongata and slightly higher than the growth rate of Paulownia fortunei (Zhao-Hua et al. 1986).

Furthermore, the sample trees have an average bark thickness of 3 mm, which is extremely narrow with its positive consequences for easier debarking processes in the sawmill and peeling processes in the plywood-mill (Olson and Carpenter 1985). On the contrary, the pith is relatively large with an average width of 16 mm (Table 1). The special problem, however, is that it is hollow throughout its length, which is a major defect in sawn timber. Thus, in the sawmill, all the pieces that contain pith should be rejected, destined for chipping (boiler feed or sale to wood-based panels).

Regarding ovality, the largest diameter is on average approximately 20% higher than the values of the smallest diameter. Regarding eccentricity, the larger radius is on average approximately 60% higher than the values of the smallest radius (Table 1). These differences imply an acceptable mean ovality of 1.2 for sawing or peeling processes, but the mean eccentricity reaches a ratio of 1.6, which is a high value that influences directly the quality of the logs for sawn timber or veneer uses, at least at the analyzed stem height. This is an important weakness of the Paulownia hybrid Cotevisa 2. Paulownia tomentosa planted in Hungary showed a similar eccentricity estimated from the maximum and minimum radius (Koman et al. 2017). This may be an important reason to lengthen the rotation for a few more years, since some studies show that eccentricity is reduced and compensated in some species of hardwoods with age, for example in ash (Oliver-Villanueva and Becker 1993) and oak (Peters 1996).

3.2 Structural and anatomical parameters

The wood of Paulownia hybrid Cotevisa 2 is clearly very light (Fig. 4a, b) and soft, like the wood of the different species and hybrids of the Paulownia genus. At the age of seven years, the very fast-growing stems of Paulownia hybrid Cotevisa 2 have a light yellow to light grey heartwood (Figs. 1e and 3a, b). The boundary between the sapwood and heartwood cannot be clearly defined. On the other side, annual growth rings are clearly visible in all cross-sections (Fig. 3a, b). The wood has a semi-ring-porous structure (Fig. 3b–d). The vessels are visible in the early wood (Fig. 3a), and the rays are visible only under optical magnification (Fig. 3b–d).

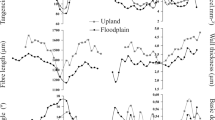

3.2.1 Ring width

The 1st year presents the wider ring with an average of 42 mm. Figure 5a shows a significant and continuous decrease in the ring width the homogeneous group formed by the 5th and 6th rings (12 and 8 mm, respectively). Therefore, after a very rapid radial growth during the first years of intensive plantation, this growth gradually declines until it stabilizes after the 5th year, with values around 10 mm per year, as other studies have also found for other Paulownia species and hybrids (Zhao-Hua et al. 1986; Jakubowski 2022).

3.2.2 Vessels

The vessels were counted and grouped into two typologies: solitary (1 vessel, Fig. 3c-S, d-S) and in radial multiples vessels (2–3 vessels, Fig. 3c-R, d-R). Solitary vessels are clearly the majority in the Paulownia hybrid Cotevisa 2 wood. In the 1st ring, solitary vessels represent 80% of the total. The percentage of solitary vessels is slightly, but significantly higher (between 85 and 88%) in the following rings (Fig. 5b).

The results obtained for the vessel density also indicate a tendency to increase the number of vessels from the 1st to the 6th ring. Thus, the 1st ring has 7 vessels/mm2, increasing slightly and gradually until the 6th ring (10 vessels/mm2). This observed vessel density variation, however, cannot be evaluated as significant, since after the ANOVA and the multiple rank test, no significant differences were found among the first five rings, only significant differences can be detected between the 6th and all previous rings (Fig. 5c). A higher vessel density was also found in mature wood compared to juvenile wood for Paulownia elongata (Bao et al. 2001).

3.3 Physical properties

3.3.1 Density

The oven-dry density is increasing progressively from the 1st ring (0.216 g/cm3) to the 5th and 6th ring (0.281 and 0.288 g/cm3, respectively) (Fig. 4a). The ANOVA analysis indicates significant differences in the oven-dry density among the growth rings, although the multiple range test does not detect significant differences between the 5th and 6th rings (Fig. 4a). The obtained results demonstrate the ultra-light density of this species. The results are very comparable with the results obtained in other studies with Paulownia elongata in China (0.209 g/cm3; Zhao-Hua et al. 1986) and Hungary (0.294 g/cm3; Koman et al. 2017), as well as Paulownia fortune planted in China (0.258 g/cm3; Zhao-Hua et al. 1986) and in Iran (0.261 g/cm3; Kiaei 2013).

The basic density shows a similar behavior to the oven-dry density. So, it is increasing progressively from the 1st ring (0.202 g/cm3) to the 5th and 6th ring (0.264 and 0.268 g/cm3) (Fig. 4b). As expected, significant differences between the basic density values in the different rings were also detected, but the multiple rank test includes the 5th and 6th rings in the same group (Fig. 4b). As expected, the basic density values are between 5 and 7% lower than the values of oven-dry density of the wood in the same rings (Fig. 4a, b). These differences are similar to those observed for the parental species of the hybrid, other species and hybrids of Paulownia in ranges from 4 to 9% (Akyildiz and Kol 2010; Kiaei 2013; Koman et al. 2017; Ab Latib et al. 2020; Koman and Feher 2020; Sedlar et al. 2020).

Usually, juvenile wood is characterized by lower density when compared with mature wood. The current results also demonstrate that oven-dry density and the basic wood density of the different growth rings of the Paulownia hybrid Cotevisa 2 increased significantly (Fig. 4a, b). These significant differences suggest that the wood from the 1st to the 4th rings could be considered as juvenile wood and from the 5th ring as mature wood. So, considering the mean values for rings 1–4 (0.225 g/cm3) and for rings 5 and 6 (0.266 g/cm3), the difference in basic density between juvenile wood and mature wood in the Paulownia hybrid Cotevisa 2 is of 19%. Lower (7%) and non-significant differences in basic density between juvenile and adult wood were measured for the species Paulownia elongata (Bao et al. 2001). The values of oven-dry and basic density for the juvenile wood of the Paulownia hybrid Cotevisa 2 are similar to those described for the juvenile wood of 4-year-old trees of the hybrids of Paulownia, 501 and Shan Tong planted in Croatia (Sedlar et al. 2020).

3.3.2 Fiber saturation (FSP) point and maximum moisture content (MMC)

The FSP is decreasing progressively from the 1st ring (45.0%) to the 5th and 6th ring (28.5%) (Fig. 4c). The statistical analysis indicates significant differences in FSP among the growth rings and it separates the 5th and 6th rings from the previous ones (Fig. 4c). So, the FPS of the wood of the Paulownia hybrid Cotevisa 2 shows the same trend as that observed for density: it decreases significantly and progressively in the wood of the different growth rings and stabilizes at a value of 28.5% in the 5th and 6th rings (Fig. 4c). The current results are similar to the measured FSP for other species of the Paulownia genus: 28.8% for Paulownia tomentosa (Akyildiz and Kol 2010) and 31.2% for Paulownia fortunei (Kiae 2013).

The MMC shows very high values of over 400%, especially in the 1st ring (Fig. 4d), which are comparable with the results reported for juvenile wood of Paulownia elongata (403%) by Bao et al. (2001). The MMC gradually and significantly decreases to values between 317 and 308% in the 5th and 6th rings, respectively (Fig. 4d). These are lower values than that of the mature wood of Paulownia elongata (372%) reported by Bao et al. (2001) and Paulownia tomentosa (350%) reported by Kiaei (2013), but clearly higher than MMC hybrid Shan Tong (around 200%) reported by Sedlar et al. (2020). The ANOVA and multiple rank test also demonstrate a significant difference between the first four rings and the 5th and 6th ring (Fig. 4d).

3.3.3 Cell wall

The percentage of the cell wall of the wood of Paulownia hybrid Cotevisa 2 was increasing gradually from the 1st ring (14%) to the 5th and 6th ring (18% and 19%, respectively) and in parallel, the porosity of the wood in the different growth rings decreases from 86% in the 1st ring to 81% in the 5th and 6th rings (Fig. 4e). The statistical tests denote significant differences between the 5th and 6th rings and the first four rings (Fig. 4e).

Xylem density is theoretically a product of porosity and proportion of cell wall in an analyzed volume or surface, i.e., the dimensions of the cell walls divided by the dimensions of the wood sample (Elliott and Brook 1967; Polge 1978; Jagels and Telewski 1990). However, xylem density is modulated by the chemical composition of the solid cell walls, which in turn controls the density of the cell walls (Vaganov et al. 2006). Xylem density is thus an aggregate of both the cell wall dimensions and cell wall composition (Tsoumis 1964). Cell wall dimensions are clearly the most important driver of intrannual and interannual wood densities (Björklund et al. 2021). The decline in the cell wall proportion from juvenile to mature wood has also been observed in other fast-growing hardwoods (Bhat et al. 2001) and softwoods (Björklund et al. 2017).

The very high MMC observed is directly related to the low percentage of the cell wall and therefore, the high porosity that the Paulownia hybrid Cotevisa 2 wood presents (Fig. 4e), which in turn determines the ultra-low density (Fig. 4a, b). The results are consistent with previous studies on Paulownia fortunei (17.4% cell wall, Kiaei 2013) and Paulownia tomentosa (19.6% cell wall, Kiaei 2013). The progressive increase in the cell wall percentage (Fig. 4e) and the decrease in porosity confirm the trends observed for density, FSP and maximum moisture content (Fig. 4a–d).

3.3.4 Dimensional stability

The longitudinal shrinkage (SL) shows very low values and in the same order of magnitude, and although no marked differences are observed, a tendency to reduction along the rings could be reflected (Fig. 6a). The multiple range test denotes significant differences in SL between the 1st and 2nd (0.25% and 0.24%, respectively) rings in comparison to the 5th and 6th rings (0.11% and 0.11%, respectively) (Fig. 6a).

The tangential shrinkage (ST) also presents the highest values in the wood of the 1st ring (5.9%), while decreasing progressively and significantly in the rest of the rings, until the 5th and 6th rings (4.5% and to 4.4%, respectively). This represents a decrease of 25% in comparison to the 1st ring (Fig. 6b).

The radial shrinkage (SR) presents similar average values in all rings. Nevertheless, the values in the first four rings are not significantly different (2.1–2.4%), in comparison with the slightly higher, but significantly different increased values of the 5th and 6th rings (2.7% and 2.9%, respectively) In any case, the minimal differences observed for SR in this statistical sample do not show a clear trend (Fig. 6c).

The mean values of all linear shrinkages (SL, ST and SR) are consistent with previously published data for different Paulownia species and hybrids (Zhao-Hua et al. 1986; Bao et al. 2001; Kiaei 2013; Koman et al. 2017; Koman and Feher 2020; Sedlar et al. 2020). The joint analysis of the results of the contractions in the three linear axes, indicates a different dimensional behavior between the wood of the 5th and 6th rings of the previous ones. This differentiation between the different rings coincides with that established for the previously measured parameters and reinforces the idea of considering the 1st to 4th growth rings as juvenile wood and the wood formed after the 5th year as adult wood.

Moreover, the resulting volumetric shrinkage (β(V)) also presents the average highest value in the first ring (8.4%). However, β(V) decreases significantly from the 1st to the 2nd ring (7.4%) and remains more or less constant until the 6th ring (7.2%) (Fig. 6d). So, the multiple range test does not denote significant differences in longitudinal shrinkage among the last five rings (Fig. 6a). The obtained values can be considered as low for the Paulownia hybrid Cotevisa 2 wood, which allows little reduction in volume between green and dry wood, and, therefore, little loss of yield after the industrial drying process. These results coincide with other studies for different species and hybrids of Paulownia, which are 7.45% for Paulownia fortunei (Kiaei 2013), 8.12% for Paulownia elongata (Zhao-Hua et al. 1986) and between 7 and 8% for other Paulownia hybrids (Koman et al. 2017; Koman and Feher 2020; Sedlar et al. 2020).

Finally, the anisotropic coefficient (ST/SR), as a key parameter for the dimensional stability of solid wood and for the drying quality, decreases continuously and progressively from the 1st ring (2.7) to the 6th ring (1.6). The ANOVA and multiple rank test demonstrate that the last two rings form a homogeneous group significantly lower than the previous four younger rings (Fig. 6e). According to the classification for drying behavior (Fernández-Golfín and Conde 2007; based on Kollmann and Côté 1968) the wood of Paulownia hybrid Cotevisa 2 would be cataloged as very nervous wood in the first rings and as calm wood in the 5th and 6th rings, contributing to reduce warping risk, mainly twist, cup and bow. This is a result of a combined almost opposite behavior in both linear shrinkages: while tangential shrinkage decreases significantly and progressively from the 1st to the 6th ring, the radial shrinkage does not present high variations and even increases slightly in the 5th and 6th rings.

4 Conclusion

The present work aimed to analyse radial variations in wood anatomical structure and physical properties of Paulownia hybrid Cotevisa 2 from fast-growing plantations. Based on the results of this study, the following conclusions can be drawn:

-

a)

Paulownia hybrid Cotevisa 2 trees can grow very quickly in intensive plantations with localized irrigation on land previously used for agriculture in the Mediterranean area, reaching DBH dimensions of approx. 30 cm in less than 7 years, thus allowing the production of minimum dimensions of logs for use in sawmills and for veneer and plywood.

-

b)

While the stems grow straight, with a very small percentage of bark and free of knots thanks to quality pruning, the main quality problem lies in the presence of a large hollow pith, which runs eccentrically in the trunk length, especially in the first years of growth of the young trees. Undoubtedly, lengthening the rotation time by a few years would significantly reduce this defect, increasing the quality wood of the logs for the best performance in the sawing and rotary veneer processes.

-

c)

Annual growth of the xylem is very accelerated during the first years, even reaching more than 40 mm of radial growth per year. However, after the 5th year, the ring width stabilizes significantly around 10 mm of annual radial growth.

-

d)

Although the paulownia wood is extremely light in weight, significant differences are observed between the first rings and the stabilization of the values from the 5th growth ring onwards, both for oven-dry density (approx. 0.285 g/cm3) and for basic density (approx. 0.265 g/cm3).

-

e)

Fiber saturation, maximum moisture content and cell wall thickness and proportion also show a similar behavior, with significant differences between the first four growth rings and after the 5th ring.

-

f)

Regarding the dimensional stability, the differences are very clear and consistent in all directions and at the volumetric level. However, the most important result is the significant variation in the anisotropic coefficient of shrinkage, which is of key importance for the industrial process of drying sawn timber. Due to the sharp drop in tangential shrinkage and the practically constant behavior of radial shrinkage from pith-to-bark, the wood goes from being very nervous wood during the first four years of growth to being calm wood from the 5th year onwards.

As the final conclusion, although we do not have data after the 6th ring, all results indicate that from the 5th year of growth, the wood of Paulownia hybrid Cotevisa 2 stabilizes in some key parameters such as the radial growth of the rings, the structure and proportion of the vessels, the structure of the cell wall, the density of the material and the behavior in terms of dimensional stability in the drying process. That is why, for practical purposes, we can indicate that the transition from juvenile to mature wood can begin from the 5th year. Taking into account the growing conditions in the experimental plantation and the production rotation established originally for 7 years, (DBH of 30 cm in the lower part of the trunks), the total proportion of juvenile wood reaches more than 60% of the total volume of the trunk in the first sections for sawn or veneer wood. Following the observed growth regime, if the rotation was extended to 10 years, the DBH would increase to 35–40 cm and the proportion of juvenile wood would decrease to approximately 40%. Finally, if it was extended to 12 years, the DBH would reach 40–45 cm and the proportion of juvenile wood would barely be 25–30%, which would considerably increase the yield, in terms of quality of the roundwood produced, in this type of plantation, with eminently productive purposes for supplying sawmills, veneer and plywood mills, as well as other wood-based panels for furniture, construction and packaging, and even if it is destined to the production of biomass and cellulose.

Data availability

The dataset is available upon request.

References

Ab Latib H, Choon Liat L, Ratnasingam J, Law EL, Abdul Azim AA, Mariapan M, Natkuncaran J (2020) Suitability of paulownia wood from Malaysia for furniture application. BioRes 15(3):4727–4737

Akyildiz MH, Kol HS (2010) Some technological properties and uses of paulownia (Paulownia tomentosa Steud.) wood. J Environ Biol 31(3):351–355

Alteyrac J, Cloutier A, Zhang SY (2006) Characterization of juvenile wood to mature wood transition age in black spruce (Picea mariana (Mill.) B.S.P.) at different stand densities and sampling heights. Wood Sci Technol 40(2):124–138

Bao F, Jiang Z, Jiang X, Lu XX, Luo XQ, Zhang SY (2001) Differences in wood properties between juvenile wood and mature wood in 10 species grown in China. Wood Sci Technol 35:363–375. https://doi.org/10.1007/s002260100099

Barbour J (2004) Wood formation and properties—wood quality. In: Burley J (ed) Encyclopedia of forest sciences. Elsevier, pp 1840–1846. https://doi.org/10.1016/B0-12-145160-7/00039-9

Bee M, Davis S, Murphy J, Piper P (2005) Product potential of paulownia timber. Austral for. https://doi.org/10.1080/00049158.2005.10676219

Bhat KM, Priya PB, Rugmini P (2001) Characterisation of juvenile wood in teak. Wood Sci Technol 34(6):517–532. https://doi.org/10.1007/s002260000067

Björklund J, Seftigen K, Schweingruber FH, Frank DC (2017) Cell size and wall dimensions drive distinct variability of earlywood and latewood density in Northern Hemisphere conifers. New Phytol 216(3):728–740. https://doi.org/10.1111/nph.14639

Björklund J, Fonti MV, Fonti P, van den Bulcke J, von Arx G (2021) Cell wall dimensions reign supreme: cell wall composition is irrelevant for the temperature signal of latewood density/blue intensity in Scots pine. Dendrochronologia 65:125785. https://doi.org/10.1016/j.dendro.2020.125785

Boruszewski P, Jankowska A, Kurowska A (2017) Comparison of the structure of juvenile and mature wood of Larix decidua Mill. from fast-growing plantations in Poland. BioRes 12(1):1813–1825

Bowyer JL, Shmulsky R, Haygreen JG (2005) Forest products and wood science: an introduction, 5th edn. Blackwell Publishing, Ames

Bredemeier M, Busch G, Hartmann L, Jansen M, Richter F, Lamersdorf NP (2015) Fast growing plantations for wood production—integration of ecological effects and economic perspectives. Front Bioeng Biotechnol 09–06:2015. https://doi.org/10.3389/fbioe.2015.00072

Burdon RD, Kibblewhite RP, Walker JCF, Megraw RA, Evans R, Cown DJ (2004) Juvenile versus mature wood: a new concept, orthogonal to corewood versus outerwood, with special reference to Pinus radiata and P. taeda. For Sci 50(4):399–415

Clark A, Daniels RF, Jordan L (2006) Juvenile/mature wood transition in loblolly pine as defined by annual ring specific gravity, proportion of latewood, and microfibril angle. Wood Fiber Sci 38(2):292–299

Darmawan W, Nandika D, Sari RK, Sitompul A, Rahayu I, Gardner D (2015) Juvenile and mature wood characteristics of short and long rotation teak in Java. IAWA J 36(4):428–442. https://doi.org/10.1163/22941932-20150112

Dowse GP, Wessels CB (2013) The structural grading of young South African grown Pinus patula sawn timber. South for J for Sci 75(1):7–17. https://doi.org/10.2989/20702620.2012.743768

Elliott GK, Brook SEG (1967) Microphotometric technique for growth-ring analysis. J Inst Wood Sci 18:24–43

Esteves B, Cruz-Lopes L, Viana H, Ferreira J, Domingos I, Nunes LJR (2022) The influence of age on the wood properties of Paulownia tomentosa (Thunb) Steud. Forests 13:700. https://doi.org/10.3390/f13050700

FAO (2022) The State of the World’s Forests 2022. Forest pathways for green recovery and building inclusive, resilient and sustainable economies. FAO, Rome. https://doi.org/10.4060/cb9360

Fernández-Golfín JI, Conde-García M (2007) Manual técnico de secado de maderas (Technical guide for timber drying). AITIM, Madrid

Fernández-Puratich H, Oliver-Villanueva JV, Lerma-Arce V, García MD, Raigón MD (2017) Estudio de Paulownia spp. como cultivo forestal de rotación corta para fines energéticos en condiciones mediterráneas. (A study of Paulownia spp. as a short-rotation forestry crop for energy uses in Mediterranean conditions). Madera y Bosques 3(23):15–27. https://doi.org/10.21829/myb.2017.2331416

Flynn H, Holder C (2001) Useful wood of the world. Forest Products Society, Madison

Geimer RL, Herian VL, Xu D (1997) Influence of juvenile wood on dimensional stability and tensile properties of flakeboard. Wood Fiber Sci 29(2):103–120

Hapla F, Saborowski J (1987) Stichprobenplanung für holzanatomische Untersuchungen (Planning of sample size for wood anatomical investigations). Holz Roh-Werkst 45:141–144

Harris JM (1977) Shrinkage and density of radiata pine compression wood in relation to its anatomy and mode of formation. N Z J for Sci 7(1):91–106

Hassler M (2022) Synonymic checklists of the vascular plants of the world. In: Bánki O, Roskov Y, Döring M, Ower G, Vandepitte L, Hobern D, Remsen D, et al. Catalogue of life checklist (12.10, Feb 2022). https://doi.org/10.48580/dfpk-3dd

Hermoso E, Mateo R, Íñiguez-González G, Montón J, Arriaga F (2016) Visual grading and structural properties assessment of large cross-section Pinus radiata D. Don Timber Biores 11(2):5312–5321. https://doi.org/10.15376/biores.11.2.5312-5321

Jagels R, Telewski FW (1990) Computer-aided image analysis of tree rings. In: Cook ER, Kairiukstis LA (eds) Methods of dendrochronology: applications in the environmental sciences. Kluwer Academic Publishers, Boston, pp 76–93

Jakubowski M (2022) Cultivation potential and uses of Paulownia wood: a review. Forests 13:668. https://doi.org/10.3390/f13050668

Johansson M, Kliger R (2002) Influence of material characteristics on warp in Norway spruce studs. Wood Fiber Sci 34(2):325–336

Kiaei M (2013) Tecnological properties of Iranian cultivated paulownia wood Paulownia fortunei. Cellulose Chem Technol 47:735–743

Kircher M (2022) Economic trends in the transition into a circular bioeconomy. J Risk Financ Manag 15:44. https://doi.org/10.3390/jrfm15020044

Kliger R (2001) Spiral grain on logs under bark reveals twist prone raw material. For Prod J 51(6):67–73

Kollmann FFP, Côté WA (1968) Solid wood vol 1 of principles of wood science and technology. Springer-Verlag, Berlin Heidelberg, New York

Koman S, Feher S (2020) Physical and mechanical properties of Paulownia clone in vitro 112. Eur J Wood Prod 78:421–423

Koman S, Feher S, Vityi A (2017) Physical and mechanical properties of Paulownia tomentosa wood planted in Hungaria. Wood Res 62(2):335–340

Kretschmann DE, Moody RC, Pellerin RF, Bendtsen BA, Cahill JM, McAlister RH, Sharp DW (1993) Effect of various proportions of juvenile wood on laminated veneer lumber. Res. Pap. FPL–RP–521. US Department of Agriculture, Forest Service, Forest Products Laboratory, Madison

Lachenbruch B, Moore JR, Evans R (2011) Radial variation in wood structure and function in woody plants, and hypotheses for its occurrence. In: Meinzer FC, Lachenbruch B, Dawson TE (eds) Size- and age-related changes in tree structure and function. Springer-Verlag, Berlin, pp 121–164

Marbun SD, Wahyudi I, Suryana J, Nawawi DS (2020) Fiber quality and juvenile-mature transition evaluation of jabon (Anthocephalus cadamba) and binuang (Octomeles sumatrana). IOP Conf Ser Earth Environ Sci 591(1):012009

McEwan A, Marchi E, Spinelli R, Brink M (2020) Past, present and future of industrial plantation forestry and implication on future timber harvesting technology. J for Res 31(2):339–351. https://doi.org/10.1007/s11676-019-01019-3

Moore JR, Cown DJ (2017) Corewood (juvenile wood) and its impact on wood utilisation. Curr for Rep 3:107–118. https://doi.org/10.1007/s40725-017-0055-2

Nawrot M, Pazdrowski W, Walkowiak R, Szymański M, Kazimierczak K (2014) Analysis of coniferous species to identify and distinguish juvenile and mature wood. J for Sci 60(4):143–153

Oliver-Villanueva JV, Becker G (1993) Wood properties of ash (Fraxinus excelsior L.) relevant to its utilization and their variability in regard to age and space (Verwendungsrelevante Holzeigenschaften der Esche (Fraxinus excelsior L.) und ihre Variabilitaet im Hinblick auf Alter und Standraum). Forst-Und-Holz 48(14):387–391

Olson JR, Carpenter SB (1985) Specific gravity, fiber length, and extractive content of young Paulownia. Wood Fiber Sci 17(4):428–438

Peters S (1996) Untersuchungen über die Holzeigenschaften der Stieleiche (Quercus robur L.) und ihre Beeinflussung durch die Bestandesdichte. (Investigations on the wood properties of English oak (Quercus robur L.) and their influence by stand density). Dissertation, University of Göttingen

Pirard R, Dal Secco L, Warman R (2016) Do timber plantations contribute to forest conservation? Environ Sci Policy 57:122–130. https://doi.org/10.1016/j.envsci.2015.12.010

Pliura A, Yu Q, Zhang SY, MacKay J, Périnet P, Bousquet J (2005) Variation in wood density and shrinkage and their relationship to growth of selected young poplar hybrid crosses. For Sci 51(5):472–482. https://doi.org/10.1093/forestscience/51.5.472

Polge H (1978) Fifteen years of wood radiation densitometry. Wood Sci Technol 12(3):187–196

Ruano A, Hermoso E (2021) Juvenile-mature wood evaluation along the bole considering the influence of silvicultural treatments. Maderas-Cienc Tecnol. https://doi.org/10.4067/s0718-221x2021000100421

Sedlar T, Sefc B, Drvodelic D, Jambrekovic B, Kucinic M, Istoc I (2020) Physical properties of juvenile wood of two Paulownia hybrids. Drvna Ind 71(2):179–184

Sikkema R, Proskurina S, Banja M, Vakkilainen E (2021) How can solid biomass contribute to the EU’s renewable energy targets in 2020, 2030 and what are the GHG drivers and safeguards in energy- and forestry sectors? Renew Energy 165:758–772

Siostrzonek E (1958) Radialzuwachs und Flächenzuwachs (Radial growth and area growth). Forstwissenschaftliches Centralblatt 77:237–254. https://doi.org/10.1007/BF01821397

Tsoumis G (1964) Microscopic measurement of the amount of cell wall substance in wood and its relationship to specific gravity. Tappi J 47:675–677

Tsoumis G (2009) Science and technology of wood: structure, properties, utilization. Van Nostrand Reinhold, New York

Vaganov EA, Hughes MK, Shashkin AV (2006) Growth dynamics of conifer tree rings: images of past and future environments, vol 183. Springer, Berlin

Wessels C, Malan FS, Nel DG, Rypstra T (2014) Variation in strength, stiffness and related wood properties in young South African-grown Pinus patula. South for J for Sci 76(1):37–46. https://doi.org/10.2989/20702620.2013.870406

Zhang SY, Ren H, Jiang Z (2021) Wood density and wood shrinkage in relation to initial spacing and tree growth in black spruce (Picea mariana). J Wood Sci 67:30. https://doi.org/10.1186/s10086-021-01965-9

Zhao-Hua Z, Ching-Ju C, Xin-Yu L, Yao-Gao X (1986) Paulownia in China: cultivation and utilization. Asian Network for Biological Sciences and International Development Research Centre, Beijing

Zobel B (1984) The changing quality of the world wood supply. Wood Sci Technol 18:1–17. https://doi.org/10.1007/bf00632127

Zobel B, Sprague JR (1998) Juvenile wood in forest trees. Springer-Verlag, Berlin

Zuazo VHD, Bocanegra JAJ, Torres FP, Pleguezuelo CRR, Martínez JRF (2013) Biomass yield potential of Paulownia trees in a semi-arid Mediterranean environment (S Spain). Int J Renew Energy Res 3(4):789–793

Acknowledgements

We thank the company CERMOTEC in Toledo (Spain) for providing the study material and the company iFOREST in Albacete (Spain) for the information on the plantation and experimental plot. We would also like to thank the anonymous reviewers and editorial office for their comments and suggestions that have contributed to improving the manuscript.

Funding

Open Access funding provided thanks to Universitat Politècnica de València by CRUE-CSIC agreement with Springer Nature.

Author information

Authors and Affiliations

Contributions

Conceptualization: MF and JVOV; Investigation: MV, MF and JVOV; Supervision: MF and JVOV; Writing – original draft: MF; Writing – reviews and editing: MF, JVOV and MV

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fos, M., Oliver-Villanueva, JV. & Vazquez, M. Radial variation in anatomical wood characteristics and physical properties of Paulownia elongata x Paulownia fortunei hybrid Cotevisa 2 from fast-growing plantations. Eur. J. Wood Prod. 81, 819–831 (2023). https://doi.org/10.1007/s00107-023-01941-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-023-01941-8