Abstract

Wood modification is an excellent way to improve material properties, prolong service life, and pave the way for new applications for timber in the built environment. The aim of this study is to establish the influence of wood species in the modification process with phenol urea formaldehyde resin. Seven hardwoods and four softwoods were compared in an identical treatment. Since the wood species is the main variable, the study provides a clear insight as to its influence on modification—something not previously investigated. Small wood blocks of all eleven species were impregnated with low-molecular weight phenol urea formaldehyde resin and were subsequently heat-cured at 150 °C. Mass and dimensions of specimens were carefully monitored throughout three cycles of oven-drying and water-soaking to determine anti-swelling efficiency, bulking coefficient, and swelling coefficient. The results showed a clear relationship between density, bulking-, and swelling coefficients. Beyond this well-known relationship it was observed that species with similar density (e.g., lime and sycamore) had significantly different bulking coefficients and anti-swelling efficiencies. Reasons for these differences, which are independent of density, are discussed. The soaking solution was analysed to determine the nature of leached substances showing a correlation between the amount of leachate and the UV-absorbance (272 nm) of the solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Commercial wood modification with thermosetting resins relies on an impregnation step, during which the liquid resin is forced into the bulk structure of the wood. The sapwood of Radiata pine (Pinus radiata) is currently the preferred species of solid wood modified in commercial processes requiring impregnation, such as Accoya and Kebony (Jones et al. 2019). Despite its availability in clear (knot-free) lengths and fast growth, the main reason for use is the excellent treatability of its sapwood, which enables a high and uniform resin uptake. This overreliance on Radiata pine and the growing demand of the wood modifying sector for such a highly permeable material have contributed to a considerable price increase in recent years.

Liquid flow during impregnation is influenced significantly by wood anatomy. Limiting factors in both softwoods and hardwoods are the pit diameter and the degree of pit aspiration (Siau 1984). Sufficient permeability is prerequisite for any wood species used for resin modification. However, permeability of solid wood can be improved by various techniques (Tarmian et al. 2020; Nath et al. 2022). In other applications, like the impregnation of veneers, permeability ceases to be a limiting factor as the dimensions through which fluid is required to flow have been radically reduced. This led to the adoption of plywood-based systems by Millett et al. (1943) in Compreg and to more recent advances in this re-emerging field (Fleckenstein et al. 2018; Bliem et al. 2020; Wascher et al. 2020). Aspects other than the permeability and availability of timber are rarely considered in the choice of wood species, and the literature lacks a comparative study that investigates how wood species with different chemical compositions and cell structures behave in the same treatment. The current study addresses this topic by focussing on the wood species as the main variable.

How can the quality of resin modification be ensured? This question must be answered on multiple levels. In the following, a list with relevant criteria is provided and subsequently discussed in more detail. Quality criteria for the impregnation modification process with thermosetting resin include:

-

Gross uptake due to resin-treatment, evaluated by:

-

weight-percent gain (WPG) of laboratory samples (requires oven-dry weight of specimen)

-

resin weight uptake in commercial sized pieces (in kg/m3)

-

-

Uniformity of resin distribution throughout the sample

-

at macroscopic level, evaluated by:

-

visual inspection (of liquid front after impregnation or drying)

-

metric information (mass and volume change in different regions of a specimen) (Millett and Stamm 1954)

-

-

at microscopic level, evaluated by:

-

microscopy (light-, electron-, spectroscopy-) to detect distribution and morphology of resin in wood cells (Behr et al. 2018)

-

-

at submicroscopic level, evaluated by:

-

-

Effectiveness of the resin within the wood

-

degree of cell wall penetration, evaluated by:

-

reduction of water-induced swelling (Hill 2006), evaluated by:

-

anti-swelling efficiency (ASE)

-

moisture-exclusion efficiency (MEE)

-

-

-

Longevity and retention of resin during service life, evaluated by:

-

quantity of leaching products (mass loss and solid residue in leachate)

-

chemical analysis of leaching solution (Kurkowiak et al. 2022)

-

It is widely accepted that resin should be distributed uniformly throughout the sample, primarily as it has a swelling effect on the wood, so stresses would develop if areas remained unmodified, while adjacent tissue was modified. This distribution can be considered at different levels of scale. Macroscopic effects such as poor impregnation or migration of resin during drying stages can be detected visually to some extent, and in commercial processes, visual inspection of a cross-section is used to monitor the location of the liquid front after impregnation, or areas of poor uptake, such as heartwood (Pitman 2020). At laboratory scale, this is often not necessary because all regions of the specimens are impregnated equally. However, small-scale effects are frequently studied in laboratory specimens such as the distribution of the resin in cell lumen or detection of resin within cell walls (Rapp et al. 1999; Behr et al. 2018; Biziks et al. 2019). Metrics such as weight percent gain (WPG) describe the overall gravimetric uptake of resin but make almost no statement about the quality of modification in terms of location or its effectiveness within the wood. It is well known that resin in the cell walls is more effective than in the cell lumen (Furuno et al. 2004). The bulking coefficient (BU) is an indicator for the amount of resin located in the cell walls, quantified in terms of the swelling caused by resin access into pore spaces usually accessed by water on wetting (Tanaka et al. 2015). However, some agents that bulk the cell wall initially are not fixed and may leach upon water exposure (Meints et al. 2018). Similarly, some resins polymerise but certain fractions, which remain unreacted due to steric hindrances in the cell wall, do leach over multiple cycles (Laborie et al. 2006). For this reason, it is useful to include longer term cyclic testing.

In terms of performance, improved dimensional stability is a defining characteristic of many modified woods (Ellis and Rowell 1982; Ormondroyd et al. 2015). A commonly adopted test for this is the anti-swelling efficiency (ASE) method during which small wood samples are subjected to cyclic water soaking and oven drying (Hill 2006). During an ASE test, the swelling of a modified group of samples is compared against unmodified controls over several wetting and drying cycles. The modified and unmodified sets should be matched where possible—i.e., from the same plank of timber or at least a plank of similar growth rate and the same species. The inability to use matched samples, for example where systems move out of the laboratory onto production scale, can cause substantial errors within the calculated results (Sargent 2022). Both the control and the modified set are soaked with deionized water for several days and then dried again. This procedure can be repeated multiple times and the swelling and water uptake of both groups are compared. Some authors reject the data of the first swelling cycle, because it may generate artificially high ASE values (Hill 2006). Information about the nature of leaching substances can also be obtained from an ASE test, by analysis of the soaking solution. Typically, the solid residue in the soaking solution is measured by simply evaporating the water from an aliquot (Grinins et al. 2019). However, chemical analytical techniques like ultraviolet spectroscopy (UV), and liquid chromatography mass spectroscopy (LC–MS) can provide more insight into the nature of leaching substances (Kurkowiak et al. 2022).

Using the ASE method, many authors have studied the dimensional stability of different wood species modified with thermosetting resins (Millett and Stamm 1954; Epmeier et al. 2004; Furuno et al. 2004; Grinins et al. 2019; Altgen et al. 2020). However, it is often difficult to compare results due to variations in resin type (melamine formaldehyde, phenol formaldehyde, urea formaldehyde etc.), resin properties (molecular weight, solids content, pH) or variations in the method (sample dimensions, soaking time, use of high relative humidity instead of soaking). Consequently, the effect that species differences have in the treatment cannot be derived from the existing literature. The present study examines the behaviour of seven hardwoods and four softwoods in this modification process. Species were chosen on the basis of different anatomy, chemistry, and density. A comparison of selected studies is provided in Table 1. Two studies in this table investigated multiple species (Shams et al. 2006; Millett and Stamm 1954). Shams et al. (2006) compared intermediate sized specimens of eight hardwoods and softwoods that were impregnated with PF-resin and subsequently densified. It was noted that the swelling capacity of the cell wall, resulting from PF-modification, differed between species. Since this study focussed on densification the authors did not conduct ASE tests. Millett and Stamm (1954) compared plank sized sapwood specimens of nine, mainly North American, wood species. Due to the specimen dimensions, the study investigated the treatability of different wood species rather than the influence of their anatomy and chemistry on the treatment. Accordingly, the quality of modification was assessed through the uniformity of the treatment comparing the swelling coefficient, density, and surface hardness in different locations along the plank. Yellow birch (Betula alleghaniensis), sweetgum (Liquidambar styraciflua), and tulipwood (Liriodendron tulipifera) showed uniform swelling coefficients across the whole length of the plank. Tulipwood also displayed a uniform density after treatment and consistent ball indentation hardness across the whole length.

2 Material and methods

2.1 Wood samples and PUF-resin

Seven hardwoods and four softwoods were selected for this study. The hardwoods were European beech (Fagus sylvatica), silver birch (Betula pendula), sycamore (Acer pseudoplatanus), willow (Salix alba), common poplar (Populus tremula), European lime (Tilia x europaea) and tulipwood (Liriodendron tulipifera). The softwoods included Southern yellow pine or SYP (this is a commercial mix of four pine species: Pinus palustris, P. elliottii, P. taeda and P. echinata), Scots pine (Pinus sylvestris), Radiata pine (Pinus radiata) and Pinus taeda. The Pinus taeda timber was procured from a single species plantation in Brazil for comparison with the mixed species SYP from North America. All timbers were sourced commercially, with requirement for low heartwood content. Visual examination on receipt and use of heartwood indicator solutions where relevant confirmed that sapwood was used in this study. Sapwood specimens from each species were cut with good alignment of the grain and growth rings to the edges of the specimen, the dimensions were 20 (r) × 20 (t) × 5 (l) mm. These were stored at ambient conditions until further processing. Every unmodified and modified test group in this study consisted of 10 specimens from the same board.

Commercial PUF-resin (Prefere 5K600M) was provided by Prefere GmbH, Germany. Prior to impregnation, the resin was diluted with deionized water to a solids content of 30% and pH 9.2. The molecular weight information as reported by Prefere is Mn = 406 (g/mol) and Mw 484 (g/mol). Potassium hydroxide (KOH) is present as an alkaline catalyst.

2.2 Resin treatment

The sample mass was measured with a 4 d.p. balance (Ohaus Explorer Analytical) and the surface area was measured with a digital calliper (2 d.p.) at the radial, tangential, and longitudinal edge of the specimen. The oven dry mass and dimensions of unmodified test blocks were determined after drying at 105 °C for 24 h (OD 0). Subsequently, samples were conditioned at ambient moisture and room temperature for 24 h prior to use. For the resin impregnation, samples were placed in a 250 ml beaker in a desiccator attached to a vacuum line. A vacuum was drawn for 20 min prior to impregnation. Then, the resin was injected through a dropping funnel until all samples were fully submerged. Ballast was used above the samples to ensure they remained below the level of the fluid throughout the procedure. A volume of 100 ml resin was used for each impregnation. Still under vacuum, the samples were immersed for 20 min, before the vacuum was released. Subsequently, the treatment solution was drained off and samples were removed from the beaker, excess resin was blotted with tissue and the mass and dimensions were noted (Imp). The samples were now carefully dried at 50 °C for 16 h to reduce the moisture content before cure. Heat curing took place at 150 °C for a duration of 8 h. The mass and dimensions after cure were noted (OD 1).

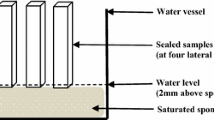

2.3 Cyclic swelling and drying

Sets of 10 modified and 10 unmodified control specimens were subjected to cyclic water soaking and oven drying. Oven dry mass and dimensions of control (OD 0) and modified groups (OD 1) were determined, as described previously. The water soaking was carried out by vacuum impregnating each test group with 100 ml deionized water, using a similar procedure to that described for resin treatment, within a beaker in a desiccator. The soaked samples remained submerged in water for 5 days at room temperature. Subsequently, excess water was removed with a tissue before mass and dimensions were noted (WS 1). Water-soaked samples were then dried at 50 °C for 16 h to eliminate moisture without initiating stresses in the samples, and then at 105 °C for 24 h. The mass and dimensions were noted (OD 2) and the procedure was repeated until three wetting and drying cycles were completed.

2.4 ASE soaking solution analysis

After each soaking cycle, the amount of leached substances was estimated by measuring the solid residue in solution by evaporation. The nature of leached substances was investigated by measuring the pH and UV absorbance at 272 nm of the leachate.

The soaking solution was transferred to a volumetric flask and diluted to a volume of 1 l, to ensure the concentration and UV data could be used for quantitative comparison. The high level of dilution was necessary to obtain meaningful results in the UV measurements within the range of the UV spectrometer used. Approximately 20 ml of the diluted solution was poured in a glass vial of known dry mass for evaporation at 105 °C. The solid residue \(SR \left[\%\right]\) was determined by dividing the dry mass with the liquid mass. The solid residue in percent was then converted to a volumetric concentration \(SR \left[\frac{g}{l}\right]\):

A small aliquot of the diluted soaking solution was transferred to a quartz cuvette for UV absorption measurement at 272 nm. This wavelength is characteristic for aromatic compounds and displays the maximum absorption peak for phenolics (Pretsch et al. 2000). Approximately 50 ml diluted soaking solution was transferred to a small beaker for pH measurement. The pH meter was calibrated with standard buffer solution at pH 4 and 7 prior to use. The procedure was performed for every test and control group of every investigated species.

2.5 Calculations of resin treatment and cyclic swelling results

The liquid resin uptake describes the mass change between the oven dry and the freshly impregnated state. The WPG describes the dry weight gain achieved after cure. The BU describes the dry volume gain after cure. They are calculated as follows:

The water-induced swelling coefficient of unmodified control groups \({S}_{control}\) relates to the swelling of oven dry unmodified data (OD 0) and the swelling coefficient of the modified groups \({S}_{mod}\) uses the oven dry treated data (OD 1). Within this study, the swelling coefficient was calculated on an area basis, to minimise error arising from longitudinal dimension data. They are calculated as follows (Ohmae et al. 2002; Hill 2006):

The resin-induced swelling coefficient \({S}_{resin}\) of modified groups described the volume gain during impregnation and relates to OD 0. It is calculated as follows:

The total water-induced swelling coefficient \(TS\) describes the volume change from the state OD 0 to WS 1 for both modified and unmodified groups. In modified groups, this coefficient includes the permanent volume change by bulking. In unmodified control groups \(TS\) is identical with \({S}_{control}\).

The relative volume \({V}_{rel}\) in the cyclic swelling experiments refers to OD 0 in the control groups and to OD 1 in the modified groups. As mentioned previously, the changes in longitudinal direction are negligible in the displayed calculation of \({V}_{rel}\). Therefore, the relative area calculation is assumed to yield values equivalent to the relative volume, while excluding the longitudinal direction as a source of error. It is calculated as follows:

The water uptake \({WU}_{i}\) describes the mass gain from each oven dry state OD i to the following water-soaked state WS i as a percentage. It is calculated as follows:

The mass loss during ASE tests \({ML}_{total}\) compares the oven dry mass of the last cycle with first one. In modified groups, the first cycle starts at OD 0 and in modified groups it starts at OD 1. It is calculated as follows:

2.6 Statistical analysis

The experimental set-up consists of two variables. Variable one describes whether a test group is modified or unmodified. Variable two is the wood species. Every wood species was tested in a modified and unmodified state giving a total of 22 test groups each containing 10 specimens.

All analyses were performed using R Statistical Software (v4.1.2; R Core Team 2021). Boxplots used in several figures show the median value, standard deviation, as well as maximum and minimum values in each test group. Linear regression models have been calculated using the R functions stat_regline_equation() and stat_cor(). Two-way analysis of variance (ANOVA) was carried out to discern significant differences at a 95% level of confidence between swelling, total swelling, and total mass loss of modified and unmodified wood. Extreme outliers have been removed from the data sets prior to ANOVA analysis using the R function identify_outliers(). ANOVA was performed using the R functions aov(). A Tukey Honest Significance Difference (HSD) test was performed on the same data to identify significant differences within each wood species. The R function TukeyHSD() was used.

3 Results and discussion

3.1 Resin treatment

Figure 1 shows the percentage liquid resin uptake in every species. There is an inverse linear relationship between the oven dry density of the unmodified wood and its liquid uptake during impregnation. This relationship is governed by the available void volume, which decreases with increasing density (Siau 1984). Figure 1 suggests that hardwoods are more variable in this relation. Certain wood species like tulipwood and beech lie above the apparent trendline that is connecting the majority of hardwood samples. These species take up more resin than their density alone suggests. The higher uptake could be linked to a higher affinity of their cell wall ultrastructure to the resin, or to a more rapid swelling behaviour during the brief immersion period. Hardwood species lying below the trendline (poplar, birch) take up less than expected for their density. Softwoods consist of only two major cell types (tracheids and parenchyma), whereas hardwoods contain additional cell types (e.g., vessels, libriform fibres etc.) which may take up dissimilar amounts of resin during the impregnation. Therefore, within the softwoods, the gradient is more clearly defined for the whole group of species studied and the liquid uptake is almost exclusively dependent on the density. Moreover, the gradient of trendline in the softwoods is steeper than in the hardwoods.

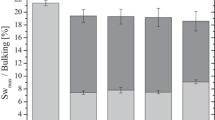

Table 2 displays the average results of modification related properties for each test group. The WPG is inversely correlated to bulking and swelling coefficients. The bulking coefficient can be influenced by resin properties, such as molecular weight and solids content, and initial liquid uptake of resin (Furuno et al. 2004; Grinins et al. 2019). It is known from these studies that higher bulking causes better dimensional stability. For the current study, we distinguish the bulking within a single species and between species. Within a single species, the bulking coefficient is an indicator for effective modification because it relates to effective cell wall penetration of resin (Fig. S1 in Supplemental Material). Across multiple species, the bulking coefficient is influenced by density, and to a smaller extent by wood anatomy. The swelling coefficient post-modification is a common indicator for the performance of modified wood. It varies between 4.5 and 9.4% (regardless of all other parameters) indicating the limit of achievable swelling reduction with this treatment. The efficiency of a treatment is expressed by the ASE, which ranges between 44.2 and 68.8% in the first cycle but decreases to 34.6 and 59.5% in the second cycle.

As indicated by anomalies in the liquid uptake in Fig. 1, there are certain trends in Table 2 that cannot be explained by density effects alone. One case study is the comparison of sycamore and lime. Sycamore has a higher density but a significantly lower bulking coefficient and ASE than lime. Therefore, the treatment was more efficient (higher ASE) in lime although modified sycamore had a better performance (lower swelling coefficient post-modification). The different behaviour of lime and sycamore may relate to differences in anatomy or chemical composition, and further study is intended. An anomaly in the softwoods is SYP and Scots pine. The SYP is denser than Scots pine but has a lower BU and ASE than the latter. This may be related to the different annual ring width in the samples used (Fig. S2 in Supplemental Material). A third case study is the comparison of birch and SYP, which have similar densities but different characteristics. Birch is a diffuse porous hardwood and SYP a softwood with pronounced differences between early and late wood. The treatment is more efficient in birch (ASE 59.3%) than in SYP (ASE 50.9%), but the swelling coefficients after modification are similar. The same trend was observed for lime (more efficient) and Scots pine (less efficient). Apparently, the swelling of hardwoods can initially be decreased more efficiently than in softwoods with similar density. However, Table 2 shows a trend that the ASE is more stable over repeated soaking cycles in the softwoods than in the hardwoods. The decrease from ASE1 to ASE2 in the softwoods ranges between 4.2% for Scots pine and 9.5% for Pinus taeda. The decrease in the hardwoods is higher ranging from 6.3% for beech to 14.1% for birch. This indicates that the resin may be better fixed in the softwood cell walls.

3.2 Cyclic swelling and drying

The swelling of modified and unmodified test groups is illustrated in Fig. 2. Note that the wood species on the y-axis are arranged by density. In unmodified wood, the water-induced swelling depends strongly on the wood density (Siau 1984). After modification, this relationship is still present, but the difference between species becomes smaller. The horizontal distance between boxplots in Fig. 2 illustrates the efficiency of the same treatment in different timbers. Low-density species like willow are relatively dimensionally stable in the unmodified state, the modification only adds little to that, and the resulting ASE is low, but performance excellent. The dashed lines represent the mean values of the whole modified and control population providing another reference point in the data set. Unmodified lime wood swells far above this average. Modified lime, however, is situated directly on the average line of the modified population. Hence, the modification was especially efficient in lime. Vice versa, unmodified poplar swells less than the average of the whole unmodified population; once modified the boxplot is located clearly above the average line and records the lowest ASE on first cycle (Table 2). This relationship is merely another illustration for the ASE, shown in Table 2. It highlights the effects of variable wood species attributes such as density and anatomy on the modification quality with PUF-resin.

Figure 3 compares the swelling of wood blocks in different fluids. The water-induced swelling was measured in the control groups after the first soak cycle. The resin-induced swelling was recorded directly after the impregnation step, but before heat curing. Two-way ANOVA was used to show that there is no significant correlation (p > 0.05) between fluid in which the wood is soaked and the swelling coefficient overall (Table S1 in Supplemental Material). The Tukey test showed that there is a significant difference in certain groups such as sycamore, tulipwood, and Radiata pine (Table S2 in Supplemental Material). In the eight remaining species, the difference is not statically significant, as indicated by the overlapping boxplots in Fig. 3. This observation was not necessarily expected, because the resin-induced swelling was measured after 20 min impregnation time, whereas the water-induced swelling was measured after 5 days. Furthermore, resin and water possess very different chemical properties in terms of polarity, average molecular weight, and pH value. These properties were expected to affect the swelling of wood blocks, which is not the case in most wood species.

Figure 4 shows the total water-induced swelling from the state OD 0 to WS 1 in modified and control groups. The total swelling is of minor importance for commercial applications of modified wood because it includes the permanent volume gain introduced by bulking, however, it also reveals information about the modification mechanism. Boxplots in Fig. 4, as well as ANOVA and Tukey tests (Table S3 and S4 in Supplemental Material) show without exception, that the total swelling of modified wood is significantly higher than in unmodified wood, although most species showed similar swelling coefficients during impregnation with water and resin (Fig. 3). Once the modified wood is cured, it swells beyond the point that is reached in the control groups just by soaking in water. This suggests certain alterations of the cell wall structure during the heat curing step. The resin is known to occupy free volumes in the cell wall that are usually filled by water (Hill et al. 2005; Hosseinpourpia et al. 2016). Generally, this is a beneficial effect because it decreases the total amount of water that can be accommodated in the cell wall. Figure 4, however, suggests that cured resin plus water swells the cell wall more than water alone. This strongly suggests that the resin curing creates new free volumes that were not previously accessible. These volumes may be found within the cured resin network, or they are created by the removal of hemicelluloses.

Figure 5 shows the relative volume in selected wood species for the modified and control groups. The relative volume changes of the remaining wood species are shown in the supplementary information (Figure S3). Note that the y-axis in Fig. 5 is customised for every species to illustrate relative trends rather than absolute numbers. The oven dry volume decreases in all modified test groups but remains largely constant in the control groups. Only unmodified willow shows a clearly decreasing oven dry volume. The water-soaked volume of modified wood is either increasing slightly (beech, lime, willow) or remains relatively constant. Unmodified wood largely retains the same water-soaked volume (except willow). As outlined by Hill (2006), a decreasing dry volume in combination with an increasing water-soaked volume indicates the loss of bulking agent. The only cases in which such a behaviour was observed are modified beech, lime, and willow. This can be due to the presence of non-bound resin molecules that bulk the cell walls initially, but are later washed out. Supposedly, these non-bound polymers have failed to crosslink in the cell wall and are hence not fixed (Laborie et al. 2006). If both the water-soaked and the dry volume decrease over cycles, this indicates the loss of thermally unstable componds (e.g., hemicelluloses) which have been degraded during the heating stage required for curing. Figure 4 suggests that following a depletion of hemicelluloses, new free volumes have been created during heat cure (Yelle and Ralph 2016; Nishida et al. 2017). The decreasing dry volume in Fig. 5 is therefore caused by the sucessive leaching of degradation products. In some cases this may be combined with a loss of bulking agent; however, the total mass loss and ASE soaking solution analysis suggest that leaching of resin is kept at a minimum.

Evolution of the relative volume over the course of the ASE experiment. Top row shows the modified test groups and bottom row the unmodified control groups. Boxplots at top of each sub-plot represent the water-soaked volume and boxplots at the bottom represent the oven dry volume. Note that the y-axes are customised for every sub-plot. The observed trends are therefore relative and not absolute

3.3 Water uptake and mass loss during cyclic swelling and drying

Figure 6 (left) shows the water uptake in modified and control groups during the second soak cycle. The water uptake in all wood species is lowered significantly by modification. This observation is exclusively due to the effect of resin weight within the calculated value for the treated wood. When resin weight is excluded, the water uptake in modified groups is higher (Figure S4 in Supplemental Material). Moreover, in both the control and the modified groups, it can be observed that the water uptake decreases with higher oven dry density of the wood species. In modified groups right of Pinus taeda, the water uptake has reached a plateau despite different densities. This may be explained by the fact that denser species take up relatively less resin, so that there is a similar volume of pore spaces available to water as in lower density species that took up more resin. Figure 6 (right) shows that in modified wood the water uptake increases with every soak cycle. This suggests that over the course of the ASE experiment water molecules find and access new pores in the modified wood which they can infiltrate (corresponding to results presented in Figs. 4, 5). In control groups, the water uptake over multiple cycles is relatively constant.

Table 3 shows the total mass loss from the first to the last oven dry state for every test group. The mass loss in control groups ranges from − 0.61% in Pinus taeda to 2.51% in sycamore relating to the percentage of water-soluble extractives. The average mass loss of modified groups is slightly higher in some cases (e.g., tulipwood, Radiata pine) and slightly lower in others (e.g., lime, sycamore). Two-way ANOVA tests have shown that there is a significant difference (p < 0.05) between the mass loss of modified and unmodified specimens (Table S5 in Supplemental Material). A pairwise comparison using the Tukey test showed the significance of this difference in most wood species (Table S6). This relatively small difference between modified and unmodified groups may arise from incomplete resin cure due to steric hindrances in the cell wall or from alkaline hemicellulose degradation (Laborie et al. 2006; Nishida et al. 2017). Table 3 suggests that these mechanisms are even more pronounced in the modified softwoods as the differenece between modified groups and controls is often higher. This might indicate the effect of different hemicellulose composition in softwoods and hardwoods (Wang et al. 2015). In certain hardwoods (willow, poplar, lime, sycamore), however, the total mass loss of modified groups and controls is not significantly different. Within these timbers, the resin seems to be especially well-fixed so that leaching is kept at a minimum.

3.4 ASE soaking solution analysis

Both the dimensional change on successive wetting cycles and the mass loss indicate that certain substances in the wood are degraded and dissolved in the soaking solution. Analysis of this solution can help to understand which processes cause the mass loss, through considering the leached products. Data tables showing the pH, the UV absorbance at 272 nm, and the solid residue of the soaking solution after dilution to constant volume (1 l) are provided in the supplementary information (Table S7).

Many species in the control group show an initially acidic pH, which increased over successive cycles (e.g., beech, SYP, lime, willow). This is related to the removal of acidic water-soluble extractives from the wood (Niazi and Johns 1980; Wang et al. 2010). The modified groups start with a pH in the neutral or mildly alkaline range and become more acidic with every cycle. This can be explained by the alkalinity of the PUF-resin (pH 9.2). The decreasing pH suggests that KOH is initially present in the wood and it is successively washed out with every cycle. Its presence may contribute to scission of labile groups within the wood cell wall as commented earlier; these could include acetate moieties of hemicellulose or monomer sugars through peeling reactions (Wang et al. 2015).

The solid residue within the soaking solution gradually decreases with every cycle in both control and the modified groups. Modified groups often show a higher solid residue than the corresponding control groups, similar to the total mass loss (Table 3). Most of the softwoods (Radiata pine, Scots pine, Pinus taeda) show a greater disparity between modified and control groups than most of the hardwoods (beech, birch, willow, sycamore) confirming another trend seen in the total mass loss. The total mass of one group should correspond to the solid residue in the soaking solution. This was the case in some groups, e.g., beech. After the second cycle, the soaking solution of the beech control group had a concentration of 0.029 g/l. In the modified groups, it was 0.1 g/l. These numbers correspond well with a mass loss of 0.034 g and 0.086 g, respectively (Table S7). This shows that substances degraded in the sample are dissolved in the soaking solution. However, a linear correlation between mass loss and solid residue could not be detected, due to deviation in the data.

Aromatic compounds in solution absorb UV light at a wavelength of 272 nm. The analysis of UV absorbance therefore helps to interpret the nature of substances leaching from the modified and unmodified samples. In most cases, the UV absorbance values decrease with each soak cycle. The UV absorbance in the modified groups is usually slightly higher than in the control groups, but as with previous data, this was not a consistent trend throughout all species. Figure 7 shows the relationship between the solid residue and the UV absorbance of the soaking solution in each soaking cycle. In the cycles 1 and 2, a moderate degree of correlation can be detected with R squared values of 0.46 and 0.38, respectively. This shows that leaching substances are UV active at wavelength 272 nm. No notable correlation can be observed in the third soak cycle.

The UV absorbance in the unmodified control groups may be explained by the leaching of aromatic wood extractives such as stilbenes, lignans and flavonoids (Sjöström 1994), but also by carbohydrate extractives that may absorb UV light in a similar region (Kaar and Brink 1991). In modified wood, an additional source of aromatics may leach into the soaking solution since the UV-absorbance is often higher. As mentioned earlier, these additional aromatic substances may involve a small fraction of PUF molecules that have failed to crosslink, due to steric hindrance. It is also possible in modified groups that aromatic compounds from Lignin-Carbohydrate-Complexes (LCCs) were degraded in the presence of the alkali and dissolved into solution during the ASE tests. The authors suggest that only trace amounts of non-cured resin are washed out.

4 Conclusion

This study provides a detailed comparison of a selection of timber species chosen on the basis of promising wood anatomical features or density, including both hardwoods and softwoods. Within this study, it was found that:

-

All timbers showed a reduction in swelling coefficient after modification. The ASE values obtained after the first soak cycle ranged from 44.2% in poplar to 68.7% in lime.

-

The liquid resin uptake is governed by the available void volume in wood (hence density), but certain species take up more (beech) or less (poplar) than their density suggests.

-

The weight percentage gain, bulking-, and swelling coefficients of different species correlate to the density of these species.

-

However, several case studies have been described in which the density cannot be made accountable for the observed differences. In these cases, we suggest that wood chemistry and ultrastructure of the cell wall played a significant role, and these effects will be investigated further.

-

Upon initial impregnation, water and PUF resin swell the cell wall to a similar extent.

-

After heat curing, the permanent swelling by bulking plus the water-induced swelling on soaking (total swelling) in modified groups is significantly greater than the water-induced swelling in unmodified controls alone. This effect was related to the creation of free volumes in the heat-curing step.

-

PUF resin is well-fixed in the wood structure as shown by comparing the total mass loss of modified and control groups and by analysis of the soaking solution.

-

However, effects that cause leaching, such as incomplete resin cure or alkaline degradation of hemicelluloses, seem to be more pronounced in softwoods than in hardwoods.

The thorough investigation of different wood species and their dimensional stability resulting from resin modification provides data to support companies and researchers in seeking alternative species for wood modification processes.

References

Altgen M, Awais M, Altgen D, Klueppel A, Maekelae M, Rautkari L (2020) Distribution and curing reactions of melamine formaldehyde resin in cells of impregnation-modified wood. Sci Rep 10(1):3366. https://doi.org/10.1038/s41598-020-60418-3

Behr G, Bollmus S, Gellerich A, Millitz H (2018) The influence of curing conditions on the properties of European beech (Fagus sylvatica) modified with melamine resin assessed by light microscopy and SEM-EDX. Int Wood Prod J 9(1):22–27. https://doi.org/10.1080/20426445.2017.1416738

Biziks V, Bicke S, Militz H (2019) Penetration depth of phenol-formaldehyde (PF) resin into beech wood studied by light microscopy. Wood Sci Technol 53:165–176. https://doi.org/10.1007/s00226-018-1058-2

Bliem P, Konnerth J, Froemel-Frybort S, Gartner C, Mauritz R, Herwijnen HWG (2020) Influence of drying and curing parameters on phenol-formaldehyde impregnated wood veneers. J Adhes 96(1–4):253–271. https://doi.org/10.1080/00218464.2019.1657015

Deka M, Saikia CN (2000) Chemical modification of wood with thermosetting resin: effect on dimensional stability and strength property. Biores Technol 73(2):179–181. https://doi.org/10.1016/S0960-8524(99)00167-4

Ellis WD, Rowell RM (1982) Reaction of isocyanates with southern pine wood to improve dimensional stability and decay resistance. Wood Fiber Sci 16(3):349–356

Epmeier H, Westin M, Rapp A (2004) Differently modified wood: comparison of some selected properties. Scand J for Res 19:31–37. https://doi.org/10.1080/02827580410017825

Fleckenstein M, Bizikis V, Mai C, Millitz H (2018) Modification of beech veneers with lignin phenol formaldehyde resins in the production of laminated veneer lumber (LVL). Eur J Wood Prod 76(3):843–851. https://doi.org/10.1007/s00107-017-1275-7

Furuno T, Imamura Y, Kajita H (2004) The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: a properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci Technol 37(5):349–361. https://doi.org/10.1007/s00226-003-0176-6

Grinins J, Bizikis V, Irbe I, Rizikovs J (2019) Water related properties of birch wood modified with phenol-formaldehyde (PF) resins. Key Eng Mater. https://doi.org/10.4028/www.scientific.net/KEM.800.246

He G, Riedl B (2004) Curing kinetics of phenol formaldehyde resin and wood-resin interactions in the presence of wood substrates. Wood Sci Technol 38(1):69–81. https://doi.org/10.1007/s00226-003-0221-5

Hill CAS, Forster SC, Farahini MRM, Hale MCD, Ormondroyd GA, Williams GR (2005) An investigation of cell wall micropore blocking as a possible mechanism for the decay resistance of anhydride modified wood. Int Biodeterior Biodegrad 55(1):69–76. https://doi.org/10.1016/j.ibiod.2004.07.003

Hill CAS (2006) Wood Modification: Chemical, Thermal and Other Processes. Wiley, West Sussex https://doi.org/10.1002/0470021748.

Hosseinpourpia R, Adamopoulos S, Mai C (2016) Dynamic vapour sorption of wood and holocellulose modified with thermosetting resins. Wood Sci Technol 50(1):165–178. https://doi.org/10.1007/s00226-015-0765-1

Huang Y, Fei B, Zhao R (2014) Investigation of low-molecular weight phenol formaldehyde distribution in tracheid cell walls of Chinese fir wood. BioResources 9(3):4150–4158. https://doi.org/10.15376/biores.9.3.4150-4158

Jones D, Sandberg D, Goli G, Todaro L (2019) Wood modification in Europe a state-of-the-art about processes, products and applications. Firenze University Press. https://fupress.com/isbn/9788864539706

Kaar WE, Brink DL (1991) Simplified analysis of acid soluble lignin. J Wood Chem Technol 11(4):465–477. https://doi.org/10.1080/02773819108051087

Klüppel A, Mai C (2013) The influence of curing conditions on the chemical distribution in wood modified with thermosetting resins. Wood Sci Technol 47(3):643–658. https://doi.org/10.1007/s00226-013-0530-2

Kurkowiak K, Hentges D, Durmarcay S, Millitz H (2022) Understanding the Mode of Action of Sorbitol and Citric Acid (SorCA) in Wood. In: Proceedings of the Tenth European conference on wood modification. Nancy, pp 209–216

Laborie MPG, Salmén L, Frazier CE (2006) A morphological study of the wood/phenol-formaldehyde adhesive interphase. J Adhes Sci Technol 20(8):729–741. https://doi.org/10.1163/156856106777638743

Meints T, Hansmann C, Gindl-Altmutter W (2018) Suitability of different variants of polyethylene glycol impregnation for the dimensional stabilization of oak wood. Polymers. https://doi.org/10.3390/polym10010081

Millett MA, Stamm AJ (1954) Wood treatment with resin-forming systems—part 3: a study of size and species limitations. A reoprt from United States Department of Agriculture and Forests Services (No.1703), Madison, Wisconsin

Millett MA, Stamm AJ, Seeborg RM (1943) Influence of manufacturing variables on the impact resistance of resin-treated wood. A reoprt from United States Department of Agriculture and Forests Services (No.1386), Madison, Wisconsin

Nath S, Waugh D, Ormondroyd GA, Spear M, Curling S, Pitman A, Mason P (2022) Percussion Nd:YAG laser-incision of radiata pine: effects of laser processing parameters and wood anatomy. Lasers Manuf Mater Process. https://doi.org/10.1007/s40516-022-00169-3

Niazi KA, Johns WE (1980) Effect of pH and buffering capacity of wood on the relation time of urea formaldehyde resin. Wood Fiber Sci 12(4):255–263

Nishida M, Tanaka T, Miki T, Hayakawa Y, Kanayama K (2017) Integrated analysis of solid-state NMR spectra and nuclear magnetic relaxation times for the phenol formaldehyde (PF) resin impregnation process into soft wood. RSC Adv 7(86):54532–54541. https://doi.org/10.1039/c7ra11295e

Nishida M, Tanaka T, Miki T, Hayakawa Y, Kanayama K (2019) Integrated analysis of modified Japanese cypress using solid-state NMR spectra and nuclear magnetic relaxation times. Cellulose 26(6):3625–3642. https://doi.org/10.1007/s10570-019-02330-2

Ohmae K, Minato K, Norimoto M (2002) The analysis of dimensional changes due to chemical treatments and water soaking for hinoki (Chamaecyparis obtusa) wood. Holzforschung 56(1):98–102. https://doi.org/10.1515/HF.2002.016

Ormondroyd GA, Spear MJ, Curling S (2015) Modified wood: review of efficacy and service life testing. Proc Inst Civ Eng Constr Mater 168(4):187–203. https://doi.org/10.1680/coma.14.00072

Pitman AJ (2020) personal communication in his role as the head of research and development of the wood modifiying company. Lignia Wood Company Ltd, Barry

Pretsch E, Buehlmann P, Affolter C (2000) Structure determination of organic compounds. Springer, Berlin

Rapp AO, Bestgen H, Adam W, Peek RD (1999) Electron energy loss spectroscopy (EELS) for quantification of cell-wall penetration of a melamine resin. Holzforschung 53(2):111–117. https://doi.org/10.1515/HF.1999.018

Sargent R (2022) Evaluating dimensional stability in modified wood: an experimental comparison of test methods. Forests. https://doi.org/10.3390/f13040613

Shams MI, Kagemori N, Yano H (2006) Compressive deformation of wood impregnated with low molecular weight phenol formaldehyde (PF) resin IV: species dependency. J Wood Sci 52(2):179–183. https://doi.org/10.1007/s10086-005-0746-3

Siau JF (1984) Transport processes in wood. Springer, Berlin

Sjöström E (1994) Wood chemistry fundamentals and applications. Carbohydr Res. https://doi.org/10.1016/0008-6215(94)90030-2

Tanaka S, Seki M, Miki T, Shigematsu I, Kanayama K (2015) Solute diffusion into cell walls in solution-impregnated wood under conditioning process I: effect of relative humidity on solute diffusivity. J Wood Sci 61(6):543–551. https://doi.org/10.1007/s10086-015-1503-x

Tarmian A, Tajrishi IZ, Oladi R, Efhamisisi D (2020) Treatability of wood for pressure treatment processes: a literature review. Eur J Wood Prod 78(4):635–660. https://doi.org/10.1007/s00107-020-01541-w

Wang X, Huang Z, Cooper P, Zhang Y, Casilla R (2010) The ability of wood to buffer highly acidic and alkaline adhesives. Wood Fiber Sci 42(3):398–405

Wang Y, Azhar S, Lindström ME, Henriksson G (2015) Stabilization of polysaccharides during alkaline pre-treatment of wood combined with enzyme-supported extractions in a biorefinery. J Wood Chem Technol 35(2):91–101. https://doi.org/10.1080/02773813.2013.875041

Wang X, Chen X, Xie X, Cai S, Yuan Z, Li Y (2019) Multi-scale evaluation of the effect of phenol formaldehyde resin impregnation on the dimensional stability and mechanical properties of Pinus massoniana Lamb. Forests 10(8):646. https://doi.org/10.3390/f10080646

Wascher R, Bittner F, Avramidis G, Bellmann M, Endres HJ, Militz H, Viöl W (2020) Use of computed tomography to determine penetration paths and the distribution of melamine resin in thermally-modified beech veneers after plasma treatment. Compos A Appl Sci Manuf. https://doi.org/10.1016/j.compositesa.2020.105821

Yelle DJ, Ralph J (2016) Characterizing phenol-formaldehyde adhesive cure chemistry within the wood cell wall. Int J Adhes Adhes 70(May):26–36. https://doi.org/10.1016/j.ijadhadh.2016.05.002

Acknowledgements

This research was financially supported by Knowledge Economy Skills Scholarships (KESS 2) through funding of the European social fund (ESF).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kupfernagel, C., Spear, M.J., Pitman, A.J. et al. Wood modification with phenol urea formaldehyde (PUF) resin: the influence of wood species selection on the dimensional stability. Eur. J. Wood Prod. 81, 5–19 (2023). https://doi.org/10.1007/s00107-022-01893-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-022-01893-5