Abstract

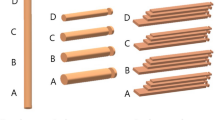

The effects of the radial force applied by a ring tip debarker and the rake angle on debarking quality of frozen and unfrozen black spruce logs were studied. A one-arm ring debarker prototype was built, which controlled the radial force, the rake angle, and the cutting and feed speeds. The experiment consisted of debarking logs using three radial forces for each temperature (− 20 °C and + 20 °C) with three rake angles (73°, 80°, and 87°). The cutting and feed speeds were kept constant with a tip overlap of 20% and average tip edge radius of 78 µm. Debarking quality was evaluated by two criteria: the proportion of bark remaining on log surfaces and the amount of wood in bark residues. Log characteristics, i.e. dimensions, eccentricity, bark thickness, knot features, bark/wood shear strength, as well as basic densities of sapwood and bark were measured. The radial force had a significant effect on debarking quality of frozen and unfrozen logs. The proportion of bark on log surfaces decreased but the amount of wood in bark residues increased as radial force increased. Thus, the radial forces of 18.9 N/mm and 18.2 N/mm were suggested for better removing frozen and unfrozen barks, respectively. In addition, the studied rake angles did not affect any of the debarking quality indicators for unfrozen logs. However, a tool with a rake angle of 87° was better for removing bark of frozen logs without negatively affecting fiber loss. Regression equations were established in order to predict the optimal radial force and rake angle taking into account the log characteristics.

Similar content being viewed by others

Data availability

The authors declare the availability of data and material.

References

ASTM D4442-16 (2016) Standard test methods for direct moisture content measurement of wood and wood-based materials. ASTM International, West Conshohocken

ASTM D2395-17 (2017) Standard test methods for density and specific gravity (relative density) of wood and wood-based materials. ASTM International, West Conshohocken

Baroth R (2005) Literature review of the latest development of wood debarking. Report A No. 27. Control Engineering Laboratory University of Oulu, Oulu

Bédard N, Laganière B (2009) Debarking enhancement of frozen logs. Part II. Infrared system for heating logs prior to debarking. Forest. Prod J 59(6):25–30

Belli ML (1996) Wet storage of hickory pulpwood in the southern United States and its impact on bark removal efficiency. Forest Prod J 46(3):75–79

Berlyn R (2000) Debarking. TECH 2000: chip and wood quality. Professional Development Committee, Pulp and Paper Technical Association of Canada, Brosard

Cáceres CB, Hernández RE, Koubaa A (2015) Effects of the cutting pattern and log provenance on size distribution of black spruce chips produced by a chipper-canter. Eur J Wood Prod 73(3):357–368

Cáceres CB, Hernández RE, Koubaa A (2016) Effects of log position in the stem and cutting width on size distribution of black spruce chips produced by a chipper-canter. Wood Fiber Sci 48(1):1–18

Calvert WW, Garlicki AM (1974) The use of ring debarkers at low temperatures. Publication No. 1334. Department of the Environment, Canadian Forest Service, Ottawa

Chahal C, Ciolkosz D (2019) A review of wood-bark adhesion: methods and mechanics of debarking for woody biomass. Wood Fiber Sci 15(3):1–12

Chow S, Obermajer A (2004) Wood-to-bark adhesion of subalpine fir (Abies lasiocarpa) in extreme temperatures. Wood Sci Technol 38:391–403. https://doi.org/10.1007/s00226-004-0247-3

Delisle JF (2018) Ressources et industries forestières du Québec, portrait statistique (2018). (Quebec’s forest resources and industries, statistical portrait) (in French). https://mffp.gouv.qc.ca/wp-content/uploads/Portrait-Statistique_2018.pdf. Accessed 19 Feb 2019

Ding FP, Ibrahim F, Gagné F (2012) MPC based ring debarking process optimization. In: 25th IEEE Canadian conference on electrical and computer engineering (CCECE). Montreal. https://doi.org/10.1109/CCECE.2012.6334987

Duchesne I, Nylinder M (1996) Measurement of the bark/wood shear strength: practical methods to evaluate debarking resistance of Norway spruce and Scots pine pulpwood. Forest Prod J 46(11/12):57–62

Harder ML, Einspahr DW, Hankey JD, Swanson JW (1975) Bark and wood properties of pulpwood species as related to separation and segregation of chip/bark mixtures. Institute of Paper Industry, Appleton

Harder ML, Van Eperen RH, Einspahr DW (1983) Method for obtaining wood/bark adhesion measurements on small samples. Wood Fiber Sci 15(3):219–222

Hatton JV (1987) Debarking of frozen wood. Tappi J 70(2):61–66

Hernández RE, Boulanger J (1997) Effect of the rotation speed on the size distribution of black spruce pulp chips produced by a chipper-canter. Forest Prod J 47(4):43–49

Hernández RE, Lessard J (1997) Effect of cutting width and cutting height on the size distribution of black spruce pulp chips produced by a chipper-canter. Forest Prod J 47(3):89–95

Hernández RE, Quirion B (1993) Effect of a chipper-canter knife clamp on the quality of chips produced from black spruce. Forest Prod J 43(9):8–14

Hernández RE, Quirion B (1995) Effect of knife clamp, log diameter, and species on the size distribution of pulp chips produced by a chipper-canter. Forest Prod J 45(7/8):83–90

Hernández RE, Llavé AM, Koubaa A (2014) Effects of cutting parameters on cutting forces and surface quality of black spruce cants. Eur J Wood Prod 72(1):107–116

Isenberg IH, Harder ML, Louden L (1980) Pulpwoods of the United States and Canada, vol 1: Conifers; vol 2: Hardwoods. Institute of Paper Chemistry, Appleton

Kharrat W, Hernández RE, Cáceres CB, Blais C (2020a) Ring debarking efficiency of frozen balsam fir logs is affected by the radial force but not by the log position on the stem. Can J For Res. https://doi.org/10.1139/cjfr-2020-0116

Kharrat W, Hernández RE, Cáceres CB, Blais C (2020b) Effects of radial force and log position on the stem on ring debarker efficiency in frozen black spruce logs. Wood Mater Sci Eng. https://doi.org/10.1080/17480272.2020.1801837

Kuljich S, Hernández RE, Blais C (2017) Effects of cutterhead diameter and log infeed position on size distribution of pulp chips produced by a chipper-canter. Eur J Wood Prod 75:747–760

Laasasenaho J, Melkas T, Aldén S (2005) Modelling bark thickness of Picea abies with taper curves. Forest Ecol Manag 206:35–47

Laganière B (2003) Manual-ring debarking. Special publication SP-525E. Forintek Canada Corp, Québec

Laganière B, Bédard N (2009) Debarking enhancement of frozen logs. Part I. Effect of temperature on bark/wood bond strength of balsam fir and black spruce logs. Forest Prod J 59(6):19–24

Laganière B, Hernández RE (2005) Effects of radial force and tip path overlap on the ring debarking efficiency of frozen balsam fir logs. Forest Prod J 55(3):44–49

Lamb FM, Marden RM (1968) Bark specific gravities of selected Minnesota tree species. Forest Prod J 18(9):76–82

Lapointe JA (1976) Optimizing the operation of ring debarkers. Project No 76–0207-01. Centre de Recherche Domtar, Research Memorandum, Senneville

Lutz JF (1978) Wood veneer: log selection, cutting, and drying. Technical Bulletin no 1577. U.S.D.A. Forest Service, Washington, DC

Marshall H, Murphy G, Lachenbruch B (2006) Effects of bark thickness estimates on optimal log merchandising. Forest Prod J 56(11):87–92

Martin RE, Crist JB (1970) Elements of bark structure and terminology. Wood Fiber 2:269–279

Meyer RW, Kellogg RM, Warren WG (1981) Relative density, equilibrium moisture content and dimensional stability of western hemlock bark. Wood Fiber 13:86–96

Miles PD, Smith WB (2009) Specific gravity and other properties of wood and bark for 156 tree species found in North America. Research Note NRS-38. Forest Service, USDA, Philadelphia

Moore GA (1987) The variation of bark/wood bond strength with moisture content of Pinus-radiata and three eucalypt species during storage. Aust For Res 17:73–78

Nurmi J, Lehtimäki J (2011) Debarking and drying of downy birch (Betula pubescens) and Scots pine (Pinus sylvestris) fuelwood in conjunction with multi-tree harvesting. Biomass Bioenerg 35(8):3376–3382. https://doi.org/10.1016/j.biombioe.2010.08.065

Prislan P, Schmitt U, Koch G, Gričar J, Čufar K (2011) Seasonal ultrastructural changes in the cambial zone of beech (Fagus sylvatica) grown at two different altitudes. IAWA J 32(4):443–459

Rowell R (1984) The chemistry of solid wood. B.S. American Chemical Society, ACS publications, Washington, DC

SAS Institute (2014) SAS/Stat user’s guide, release 9.4 ed. SAS Institute Inc., Cary

Smith JHG, Kozak A (1971) Thickness, moisture content, and specific gravity of inner and outer bark of some Pacific Northwest trees. Forest Prod J 21(2):38–40

Ugulino B, Cáceres CB, Hernández RE, Blais C (2020) Influence of temperature and moisture content on bark/wood shear strength of black spruce and balsam fir logs. Wood Sci Technol 54:963–979

Wilcox H, Czabator F, Girolami B (1954) Seasonal variations in bark-peeling characteristics of some Adironack pulpwood species. J Forest 52(5):338–342

Wilhelmsson L, Arlinger J, Spangberg K, Lundqvist S, Grahn T, Hedenberg O, Olsson L (2002) Models for predicting wood properties in stems of Picea abies and Pinus sylvestris in Sweden. Scand J Forest Res 17(4):330–350. https://doi.org/10.1080/02827580260138080

Zhang SY, Koubaa A (2009) Les résineux de l'Est du Canada: écologie forestière, caractéristiques, transformation et usages (Softwoods in eastern Canada: forest ecology, characteristics, processing and uses). Forintek Canada Corporation, Quebec (in French)

Funding

Funding for this project was provided by the Natural Sciences and Engineering Research Council of Canada (NSERC) and DKSPEC Inc. The authors thank DKSPEC Quebec, Canada for providing the knife arms and tips. The authors also thank Félix Pedneault, Jean Ouellet, David Lagueux, Daniel Bourgault, Réjean Demers, and Maxime St-Michel for their valuable assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kharrat, W., Hernández, R.E., Cáceres, C.B. et al. Influence of radial force and rake angle on ring debarking efficiency of frozen and unfrozen black spruce logs. Eur. J. Wood Prod. 79, 629–643 (2021). https://doi.org/10.1007/s00107-020-01640-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01640-8