Abstract

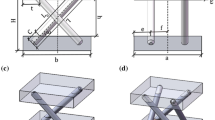

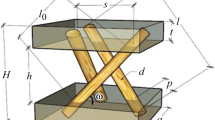

In this paper, a wood-based X-type lattice sandwich structure was manufactured via a type of insertion-glue method. Oriented strand board (OSB) was used as panel, birch was used as core and epoxy resin was used as adhesive. The compression behavior of the wood-based X-type lattice sandwich structure with different drilling depth (9 mm, 12 mm, and 15 mm), core spacing (12 mm, 30 mm and 48 mm) and core size (L50D8, L60D8) was investigated by a flatwise compressive test and a theoretical model was established to study the elastic constitutive relationship of the X-type lattice sandwich structure, including the equivalent compressive strength/modulus, and the specific strength. Results from the flatwise compressive test and the theoretical model showed that the failure modes of the wood-based X-type lattice sandwich structure were mainly shear failure of the core. The experimental values of compression modulus were less than the theoretical values. The deeper the depth of the drill hole, the shorter the core spacing, and the smaller the core size, the greater the compressive performance of the wood-based X-type lattice sandwich structure.

Similar content being viewed by others

References

Barotto AJ, Monteoliva S, Gyenge J, Martinez-Meier A, Fernandez ME (2018) Functional relationships between wood structure and vulnerability to xylem cavitation in races of Eucalyptus globulus differing in wood density. Tree Physiol 2:243–251

Bažant ZP, Beghini A (2004) Sandwich buckling formulas and applicability of standard computational algorithm for finite strain. Compos Part B 35:573–581

Deshpande VS, Fleck NA (2001) Collapse of truss core sandwich beams in 3-point bending. Int J Solids Struct 38:6275–6305

Evans AG, Hutchinson JW, Fleck NA, Ashby MF, Wadley HNG (2001) The topological design of multifunctional cellular metals. Prog Mater Sci 46:309–327

Fan HL, Meng FH, Yang W (2006) Mechanical behaviors and bending effects of carbon fiber reinforced lattice materials. Arch Appl Mech 10–12:635–647

Fan HL, Meng FH, Yang W (2007) Sandwich panels with Kagome lattice cores reinforced by carbon fibers. Compos Struct 4:533–539

Hao MR, Hu YC, Wang B, Liu S (2017) Mechanical behavior of natural fiber-based isogrid lattice cylinder. Compos Struct 176:117–123

Hu SY, Guan X, Guo MH, Wang JM (2018) Environmental load of solid wood floor production from larch grown at different planting densities based on a life cycle assessment. J For Res 5:1443–1448

Jin MM, Hu YC, Wang B (2015) Compressive and bending behaviours of wood-based two-dimensional lattice truss core sandwich structures. Compos Struct 124:337–344

Jinshi HZ, Umer R, Cantwell WJ (2016) The fabrication and mechanical properties of novel composite lattice structures. Mater Design 91:286–293

Kim T, Hodson HP, Lu TJ (2004) Fluid-flow and endwall heat-transfer characteristics of an ultralight lattice-frame material. Int J Heat Mass Transf 47:1129–1140

Lee BC, Lee KW, Byun JH, Kang KJ (2012) The compressive response of new composite truss cores. Compos Part B 2:317–324

Lee MG, Yoon JW, Han SM, Suh YS, Kang KJ (2014) Bending response of sandwich panels with discontinuous wire-woven metal cores. Mater Design 55:707–717

Li XW, Hu YC (2019) Luminescent films functionalized with cellulose nanofibrils/Cd Te quantum dots for anti-counterfeiting applications. Carbohydr Polym 203:167–175

Li S, Qin JK, Li CC, Feng YX, Zhao X, Hu YC (2018a) Optimization and compressive behavior of composite 2-D lattice structure. Mech Adv Mater Struct 27(14):1213–1222

Li XH, Liu YZ, Yu YY, Chen WS, Liu YH, Yu HP (2018b) Nanoformulations of quercetin and cellulose nanofibers as healthcare supplements with sustained antioxidant activity. Carbohydr Polym 207:160–168

Li Y, Fu Q, Yang X, Berglund L (2018c) Transparent wood for functional and structural applications. Philos Trans R Soc A 376(2112):20170182

Li S, Qin JK, Wang B, Zheng TT, Hu YC (2019) Design and compressive behavior of a photosensitive resin-based 2-D lattice structure with variable cross-section core. Polymers 11:186

Lim CH, Jeon I, Kang KJ (2009) A new type of sandwich panel with periodic cellular metal cores and its mechanical performances. Mater Design 30:3082–3093

Lu T, Liu S, Jiang M, Xu X, Wang Y, Wang Z, Zhou Z (2014) Effects of modifications of bamboo cellulose fibers on the improved mechanical properties of cellulose reinforced poly (lactic acid) composites. Compos Part B 62:191–197

Min X, Zhi C (2004) Effects of different modifiers on the properties of wood-polymer composites. J Forestry Res 15(1):77–79

Munir MT, Belloncle C, Irle M, Federighi M (2019) Wood-based litter in poultry production: a review. World Poult Sci J 75:5–16

Nguyen VD, Nguyen TT, Zhang AH, Hao JX, Wang WH (2019) Effect of three tree species on UV weathering of wood flour-HDPE composites. J For Res 31(3):1071–1079

Perrin M, Yahyaoui I, Gong X (2019) Acoustic monitoring of timber structures: Influence of wood species under bending loading. Constr Build Mater 208:125–134

Qin JK, Li XW, Shao YL, Shi KH, Zhao X, Feng TS, Hu YC (2018) Optimization of delignification process for efficient preparation of transparent wood with high strength and high transmittance. Vacuum 158:158–165

Qin JK, Zheng TT, Li S, Cheng YP, Xu QY, Ye GY, Hu YC (2019) Core configuration and panel reinforcement affect compression properties of wood-based 2-D straight column lattice truss sandwich structure. Eur J Wood Prod 77(4):539–546

Shan HY, Xiao J, Shang W, Li N (2012) Compression modulus test and analysis of x-cor sandwich structure. Aviat Dyn Rep China 4:782–788

Umer R, Barsoum Z, Jishi HZ, Ushijima K, Cantwell WJ (2018) Analysis of the compression behaviour of different composite lattice designs. J Compos Mater 6:715–729

Wang B, Wu LZ, Jin XJ, Du SY, Sun YG, Ma L (2010) Experimental investigation of 3D sandwich structure with core reinforced by composite columns. Mater Design 31(1):158–165

Wang B, Wu LZ, Ma L, Feng JC (2011) Low-velocity impact characteristics and residual tensile strength of carbon fiber composite lattice core sandwich structures. Compos Part B 42(4):891–897

Wang B, Xiong J, Wang XJ, Ma L, Zhang GQ, Wu LZ, Feng JC (2013) Energy absorption efficiency of carbon fiber reinforced polymer laminates under high velocity impact. Mater Design 50:140–148

Wang B, Zhang GQ, He QL, Ma L, Wu LZ, Feng JC (2014a) Mechanical behavior of carbon fiber reinforced polymer composite sandwich panels with 2-D lattice truss cores. Mater Design 55:591–596

Wang B, Zhang GQ, Wang SX, Ma L, Wu LZ (2014b) High velocity impact response of composite lattice core sandwich structures. Appl Compos Mater 21(2):377–389

Wang B, Hu JQ, Li YQ, Yao YT, Wang SX, Li Ma (2018) Mechanical properties and failure behavior of the sandwich structures with carbon fiber-reinforced X-type lattice truss core. Compos Struct 185:619–633

Wang HG, Zhang JF, Fu HT, Wang WH, Wang QW (2019) Effect of an antioxidant on the life cycle of wood flour/polypropylene composites. J For Res 31(4):1435–1443

Weaver TJ, Jensen DW (2000) Mechanical characterization of a graphite∕epoxy iso truss. J Aerosp Eng 13:23–35

Yuan FP, Ou RX, Xie YJ, Wang QW (2013) Reinforcing effects of modified Kevlar® fiber on the mechanical properties of wood-flour/polypropylene composites. J For Res 24(1):149–153

Zhang JF, Wang HG, Ou RX, Wang QW (2018) The properties of flax fiber reinforced wood flour/high density polyethylene composites. J For Res 29(2):533–540

Zheng TT, Cheng YP, Li S, Zhang Y, Hu YC (2020a) Mechanical properties of the wood-based X-type lattice sandwich structure. BioResources 15:1927–1944

Zheng TT, Yan HZ, Li S, Cheng YP, Zou LX, Hu YC (2020b) Compressive behavior and failure modes of the wood-based double X-type lattice sandwich structure. J Build Eng 30:101176

Zheng TT, Zou LX, Hu YC (2020c) Short beam shear properties and failure modes of the wood-based X-type lattice sandwich structure. J For Res. https://doi.org/10.1007/s11676-020-01137-3

Acknowledgements

Supports of National Natural Science Foundation of China (31470581), Fundamental Research Funds for the Central Universities (2572016EBJ1) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zou, L., Zheng, T., Li, S. et al. Compression behaviour of the wood-based X-type lattice sandwich structure. Eur. J. Wood Prod. 79, 139–150 (2021). https://doi.org/10.1007/s00107-020-01597-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01597-8