Abstract

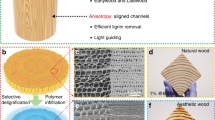

To efficiently harvest sunlight for consistent and uniform indoor lighting, an alternative solution is proposed by introducing 2–5 cm thick translucent wood composites as the wall material for a house model; these composites are prepared by H2O2 steam delignification and infiltration with epoxy resin. Although the transmittance of these materials is only 40%, the light intensity inside the house model with 2 cm thick translucent wood walls is more uniform and higher than that inside the house model with a 0.5 cm transparent wood rooftop in both the morning and afternoon of a sunny day as well as throughout overcast days, because the east, south, and west walls capture more light in the morning, at noon, and in the afternoon, respectively. Moreover, unlike transparent wood rooftops, the light intensity inside the house model with translucent wood walls increases from rooftop to ground, and this increasing light intensity is beneficial to daily life. Finally, a light intensity of 600 lux can be attained at a spot 10 cm from the 5 cm thick translucent wall, although the transmitted light intensity of the wall is only 20% of the environmental light. The demonstrated 2–5 cm thick translucent wood composites exhibit great potential for application as a building wall material to capture outside environmental light, especially when combined with a pioneering 0.5 cm thick transparent wood rooftop.

Similar content being viewed by others

References

BDOE (2016) Buildings Department of Energy http://energy.gov/eere/efficiency/buildings. Accessed Apr 2016

BEDB (2016) Buildings Energy Data Book http://buildingsdatabook.eren.doe.gov/. Accessed Apr 2016

Bellia L, Cesarano AG, Iuliano F, Spada G (2008) Daylight glare: a review of discomfort indexes. http://www.Fedoa.unina.it/13121/bellia_paper.pdf. Accessed 31 March 2008

Borisuit A, Linhart F, Scartezzini JL, Münch M (2015) Effects of realistic office day lighting and electric lighting conditions on visual comfort, alertness and mood. Light Res Technol 47:192–209

Chauvel P, Collins JB, Dogniaux R, Longmore J (1982) Glare from windows: current views of the problem. Light Res Technol 14:31–46

Fink S (1992) Transparent wood—a new approach in the functional study of wood structure. Holzforschung 46:403–408

Gan WT, Xiao SL, Gao LK, Gao RN, Li J, Zhan XX (2017a) Luminescent and transparent wood composites fabricated by PMMA and γ-Fe2O3@YVO4:Eu3+ nanoparticles impregnation. ACS Sustain Chem Eng 5:3855–3862

Gan WT, Gao LK, Xiao SL, Zhang WB, Zhan XX, Li J (2017b) Transparent magnetic wood composites based on immobilizing Fe3O4 nanoparticles into a delignified wood template. J Mater Sci 52:3321–3329

He Z, Wu H, Cao Y (2014) Recent advances in polymer solar cells: realization of high device performance by incorporating water/alcohol-soluble conjugated polymers as electrode buffer layer. Adv Mater 26:1006–1024

Lewis NS (2007) Toward cost-effective solar energy use. Science 315:798–801

Li T, Zhu MW, Yang Z, Song JW, Dai JQ, Yao YG, Luo W, Pastel G, Yang B, Hu LB (2016a) Wood composite as an energy efficient building material: guided sunlight transmittance and effective thermal insulation. Adv Energy Mater 6:1601122

Li YY, Fu QL, Yu S, Yan M, Berglund L (2016b) Optically transparent wood from a nanoporous cellulosic template: combining functional and structural performance. Biomacromolecules 17:1358–1364

Li YY, Vasileva E, Sychugov I, Popov S, Berglund L (2018a) Optically transparent wood: recent progress, opportunities and challenges. Adv Opt Mater. https://doi.org/10.1002/adom.201800059

Li YY, Yang X, Fu QL, Rojas R, Yan M, Berglund L (2018b) Towards centimeter thick transparent wood through interface manipulation. J Mater Chem A 6:1094–1101

Li HY, Guo XL, He YM, Zheng RB (2019) A green steam-modified delignification method to prepare low-lignin delignified wood for thick, large highly transparent wood composites. J Mater Res 34:932–940

Nejat P, Jomehzadeh F, Taheri MM, Gohari M, Majid MZA (2015) A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew Sustain Energy Rev 43:843–862

Pokhrel D, Viraraghavan T (2004) Treatment of pulp and paper mill wastewater—a review. Sci Total Environ 333:37–58

Rotzetter CCA, Schumacher CM, Bubenhofer SB, Grass RN, Gerber LC, Zeltner M, Stark WJ (2012) Thermo responsive polymer induced sweating surfaces as an efficient way to passively cool buildings. Adv Mater 24:5352–5356

Segmehl JS, Studer V, Keplinger T, Burgert I (2018) Characterization of wood derived hierarchical cellulose scaffolds for multifunctional applications. Materials 11:517. https://doi.org/10.3390/ma11040517

Song JW, Chen CJ, Wang CW, Kuang YD, Li YF, Jiang F, Li YJ, Hitz E, Zhang Y, Liu BY, Gong A, Bian HY, Zhu JY, Zhang JH, Li J, Hu LB (2017) Superflexible wood. ACS Appl Mater Interfaces 28:23520–23527

Yaddanapudi HS, Hickerson N, Saini S, Tiwari A (2017) Fabrication and characterization of transparent wood for next generation smart building applications. Vacuum 146:649–654

Yi ST, Kim JK, Oh TK (2003) Effect of strength and age on the stress–strain curves of concrete specimens. Cem Concr Res 33:1235–1244

Yu ZY, Yao YJ, Yao JN, Zhang LM, Chen Z, Gao YF, Luo HJ (2017) Transparent wood containing CsxWO3 nanoparticles for heat-shielding-window applications. J Mater Chem A 5:6019–6024

Zhu HL, Luo W, Ciesielski PN, Fang ZQ, Zhu J, Henriksson Y, Himmel GME, Hu LB (2016a) Wood-derived materials for green electronics, biological devices, and energy applications. Chem Rev 116:9305–9374

Zhu MW, Song JW, Li T, Gong A, Wang YB, Dai JQ, Yao YG, Luo W, Henderson D, Hu LB (2016b) Highly anisotropic, highly transparent wood composites. Adv Mater 28:5181–5187

Acknowledgements

The financial support for this research was provided by Joint Special Project of Agricultural Basic Research in Yunnan (2017FG001036) and the National Natural Science Foundation of China (41563008, 31100420).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, H., Guo, X., He, Y. et al. House model with 2–5 cm thick translucent wood walls and its indoor light performance. Eur. J. Wood Prod. 77, 843–851 (2019). https://doi.org/10.1007/s00107-019-01431-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-019-01431-w