Abstract

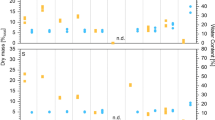

Three wood particle types of different origin [knife ring flaker (KRF), hammer mill (HM), sawmill plant] for the manufacture of extruded particleboards were characterized by conventional sieve analysis and image analysis-based particle size measurement. Sieve analysis was performed following two different approaches (on-site, off-site). Image analysis-based measurement was done applying the so-called QICPIC apparatus from Sympatec GmbH (Clausthal-Zellerfeld, Germany). It was found that the size distributions of particles derived from timber production (sawdust) were different in comparison to those of KRF or HM manufacture.

Similar content being viewed by others

References

Benthien JT, Sommerhuber P, Heldner S, Ohlmeyer, Seppke B, Krause A (2017) Influence of material origin on the size distribution of wood particles for wood-plastic composite (WPC) manufacture. Eur J Wood Prod 75(3):477–480

Berggren P (2014) Industrialisierung moderner Leichtbauwerkstoffe für den Möbelbau [Industrialization of modern light-weight materials for furniture construction]. Leichtbau-Symposium 2014, 4. December 2014, Herford, Germany. In: Benthien JT (2014) Mega-Trend, Zukunftsmusik oder Sackgasse? [Mega-trend, visions of the future or dead end?]. Holz-Zentralblatt 2014(3):58–59

Dunky M, Niemz P (2002) Holzwerkstoffe und Leime—Technologie und Einflussfaktoren [Wood-based panels and adhesives—technology and influencing factors]. Springer, Berlin

Ganster A (2014) Verfahrenstechnik der Herstellung leichter stranggepresster Vollspanplatten [Process technology of solid extruded light-weight particleboard]. Master thesis, University of Hamburg, Germany

Plinke B (1987) Rechnergestützte Partikelmessung an Materialien der Holzwerkstoffindustrie [Computer-aided particle size measurement on materials of the wood-based panel industry]. Holz Roh Werkst 54:315–318

Acknowledgements

The authors would like to thank Mr. Axel Ganster for providing particle materials and providing data from on-site sieve analysis. We also thank all those persons and companies who where engaged in supporting this master’s thesis. Mr. Hannes Wagner is thanked for performing off-site sieve analysis at the Thünen Institute of Wood Research. The Company Sympatec GmbH (Clausthal-Zellerfeld, Germany) is acknowledged for the cooperative collaboration in processing the commissioned measurement job.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benthien, J.T., Heldner, S. & Ohlmeyer, M. Size distribution of wood particles for extruded particleboard production determined by sieve analysis and image analysis-based particle size measurement. Eur. J. Wood Prod. 76, 375–379 (2018). https://doi.org/10.1007/s00107-017-1215-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1215-6