Abstract

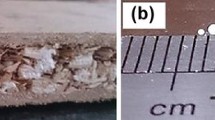

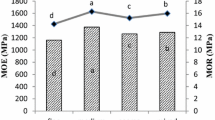

In this study three types of layered lightweight particleboard were produced by using different amounts of expandable polystyrene in the core layer as the filler material. The objective of this study was to compare the effect of varying amounts of expandable filler (5, 10 and 15 %) for two panel densities (450 and 500 kg/m3) and two panel thicknesses (16 and 19 mm) on the panel properties. The results showed that using expandable fillers has a significant effect on the bending properties, internal bond, edge screw withdrawal resistance, thickness swelling and water absorption. The surface soundness and face screw withdrawal resistance were not affected by the usage of expandable filler, as it depends mainly on the quality and density of the surface layer. Panel density and panel thickness also have significant influence on the physical and mechanical properties of the panels produced. Physical and mechanical properties of the boards did not dramatically change when the amount of expandable filler was increased from 5 to 15 %.

Similar content being viewed by others

References

Boehme C (1991) Thickness swelling of chip boards for furniture in view of the CEN-standardization (In German). Holz Roh Werkst 49(6):239–241

Dix B, Meinlschmidt P, Thole V (2008) Lightweight particleboards made from annual and perennial plants. International Panel Products symposium, Espoo, Finland

Eckelman CA (1975) Screw holding performance in hard woods and particleboard. For Prod J 25(6):30–35

EPF (2013) European Panel Federation, Annual Report 2010/2012. Brussels, Belgium, 298 pp

FAO Statistical Yearbook (2013) World food and agriculture. Food and Agriculture Organization of the United Nations, 307 pp

Frühwald A, Lüdtke J, Barbu M.C, Thömen H, Welling J (2009) The trend towards lightness: the wood-based panel sector and a new type of lightweight panel. In: Proceedings: the 7th international conference in “Wood Science and Engineering in the Third Millenium”—ICWSE 2009. Brasov: Transsilvania University, pp 263–269

Horvath JS (1994) Expanded polystyrene (EPS) geofoam: an introduction to material behavior. Geotext Geomembr 13(4):263–280

Mantau U, Saal U, Prins K, Steierer F, Lindner M, Verkerk H, Eggers J, Leek N, Oldenburger J, Asikainen A, Anttila P (2010) EUwood—real potential for changes in growth and use of EU forests. Final report. Hamburg, Germany, June 2010, 160 pp

Meinlschmidt P, Schrip A, Dix B, Thole V, Brinker N (2008) Agriculture residues with light parenchyma cells and expandable filler materials for the production of lightweight particleboards. International Panel Products Symposium, Espoo, Finland

Michanickl A (2006) Development of a new light wood-based panel. 5th European wood-based panel symposium. Hannover, Germany

Paoletti S, Spinelli M, Amico M (2012) The European Market for RTA Furniture. Centre for Industrial studies (CSIL). Milano, MI, Italy, 187 pp

Pepke E (2013) Forest Products Annual Market Review. UNECE: United Nations Economic Commission for Europe/Food and Agriculture Organization of the United Nations, Forestry and Timber Section, Geneva, Switzerland, 155 pp

Ritter N, Kharazipour A (2009) Development of three- layered popcorn based particleboards by a combination of maize and wood. In: Kharazipour A (ed) Review of forests, wood products and wood biotechnology of Iran and Germany—part III. Universität Göttingen, Göttingen, pp 1–10

Roffael E, Rauch W (1972) Influence of density on the swelling behaviour of phenolic resin bonded particle (In German). Holz Roh Werkst 30(5):178–181

Schirp A, Dix B, Meinlschmidt P, Thole V (2008) Lightweight Particleboards made from annual and perennial plants or based on foamed adhesives. In: Proceedings: the 42nd international wood composites symposium, Seattle, Washington, USA

Schulte M, Frühwald A (1996) Some investigations concerning density profile, internal bond and relating failure position of particleboard. Holz Roh Werkst 54(5):289–294

Schulz T, Hänel W (2010) Leichte Zutaten (Light ingredients) (In German) HK, Holz- Kunstst.verarb. 45(6):75–77

Seemann C (2011) New generation of wood-based materials—it does not always have to be wood (In German). GreCon wood symposium, 15–16 September, Hannover, Germany

Shalbafan A, Luedtke J, Welling J, Fruehwald A (2013a) Physiomechanical properties of ultralightweight foam core particleboards: different core densities. Holzforschung 67(2):169–175

Shalbafan A, Welling J, Luedtke J (2013b) Effect of processing parameters on physical and structural properties of lightweight foam core sandwich panels. Wood Mater Sci Eng 8(1):1–12

Thömen H (2008) Lightweight panels for the European furniture industry: some recent developments. In: Medved S (ed) Workshop proceedings: lightweight wood-based composites; production, properties and usage, Bled, Slovenia, pp 1–13

Weinkötz S (2012) Kaurit® Light for lightweight wood-based panels. (In German). Second symposium on lightweight furniture, 23–24 May, Lemgo, Germany

Acknowledgments

The authors wish to thank Tarbiat Modares University and Thünen Institute for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shalbafan, A., Tackmann, O. & Welling, J. Using of expandable fillers to produce low density particleboard. Eur. J. Wood Prod. 74, 15–22 (2016). https://doi.org/10.1007/s00107-015-0963-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0963-4