Abstract

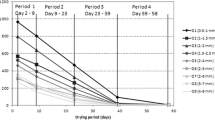

The accuracy and precision of moisture content (MC) and specific gravity (SG) measurements were tested on two industrial on-line measurement devices using microwave technology: the Metriguard DME 2800 and the Mecano MVA. Both devices were installed in a laboratory measurement line, and to obtain accuracy and precision of measurements, in total 137 spruce veneer sheets and 51 birch veneer sheets were tested. Before measurement, the spruce veneer sheets were conditioned to four different nominal MC classes between 4 and 16 % and birch veneers to three classes between 4 and 10 %. The veneer sheets were passed through the measurement devices three times. After measurement, the MC and SG of each veneer sheet were assessed gravimetrically. Using microwave technology the MC and SG of spruce and birch veneers can be measured with good accuracy and precision. The root mean square error (RMSE) for MC measurements of the spruce veneer sheets was 0.2 % on both devices and for birch veneers it was 0.7 % for DME and 0.5 % for MVA. The RMSE for the spruce SG measurement was 0.008 for both devices and for birch veneers it was 0.013 for the DME and 0.022 for the MVA.

Similar content being viewed by others

References

Antikainen T, Rohumaa A, Hughes M, Kairi M (2007) Measurement of moisture content and density in Birch (Betula pendula) Veneer using microwave technology. In: Proceedings of international symposium of Veneer and processing and products

Baldwin RF (1995) Plywood and veneer-based products, manufacturing practices (Wood technology books series). Miller Freeman, San Francisco

Bentley JP (1983) Principles of measurement systems. Longman Group Limited, New York

Bevington RP, Robinson DK (1992) Data reduction and error analysis for the physical sciences, 2nd edn. McGraw-Hill Inc, USA

Bishop CM (1995) Neural networks for pattern recognition. Department of computer science and applied mathematics Aston University Birmingham. Clarendon Press, Oxford

Burdurlu E, Kilic M, IIce AC, Uzunkavak O (2007) The effects of ply organization and loading direction on bending strength and modulus of elasticity in laminated veneer lumber (LVL) obtained from beech (Fagus orientalis L.) and lombardy poplar (Populus nigra L.). Construction and Building Materials 21(8):1720–1725

Christiansen AW (1990) How overdrying wood reduces its bonding to phenol-formaldehyde adhesives: a critical review of the literature. Part I physical responses. Wood Fiber Sci 22:441–459

Fischer M (1985) The Measurement of moisture content of veneer with radiowaves, Master thesis, Helsinki University of Technology, Radio Laboratory, pp 66

Fischer M, Vainikainen P, Nyfors E (1995) Design Aspects of stripline resonator sensors for industrial applications. J Microw Power Electromagn Energy 30(4):246–257

Fischer M, Nyfors E, Vainikainen P (1996) On the permittivity of wood and the on-line measurement of veneer sheets. In: Kraszewski A (ed) Microwave aquametry. IEEE Press, New York, pp 347–354

Haykin S (1999) Neural networks, a comprehensive foundation, 2nd edn. Prentice-Hall, USA

Kairi M, Helminen P (1996) Strength-Grading of Veneer Sheets. US Patent 5,524,771

Kollmann FFP, Côté WA (1968) Principles of wood science and technology, I Solid Wood. Springer, Germany

Marra AA (1992) Technology of wood bonding. Principles in practice. Springer, New York

Mitra A (1998) Fundamentals of quality control and improvement, 2nd edn. Prentice Hall, USA

Nyfors E (2000) Industrial microwave sensors––a review. Subsurf Sens Technol Appl 1(1):23–43

Nyfors E, Vainikainen P (1989) Industrial microwave sensors. Artec House Inc., USA

Okamura S (2000) Microwave technology for moisture measurement. Subsurf Sens Technol Appl 1(2):205–227

Sahin H, Nurgül A (2004) Dielectric properties of hardwood species at microwave frequencies. J Wood Sci 50:375–380

Schajer GS, Orham FB (2006) Measurement of wood grain angle, moisture content and density using microwaves. Holz Roh Werkst 64:483–490

Taylor JR (1997) An introduction to error analysis, the study of uncertainties in physical measurements, 2nd edn. University science books, USA

Vainikainen PV, Nyfors EG, Fischer MT (1987) Radiowave sensor for measuring the properties of dielectric sheets: application to Veneer moisture content and mass per unit area measurement. IEEE Trans Instrum Meas IM-36(4)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Antikainen, T., Rohumaa, A., Hughes, M. et al. Comparison of the accuracy of two on-line industrial veneer moisture content and density measurement systems. Eur. J. Wood Prod. 73, 61–68 (2015). https://doi.org/10.1007/s00107-014-0865-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-014-0865-x