Abstract

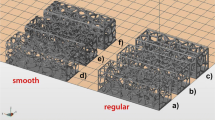

In the runner system design for aluminum gravity castings, ceramic foam filters were used for reducing the velocity of liquid metal to avoid “bifilm” defects resulting from a high gating velocity (over its critical gating velocity). In this study, three types of runner systems incorporating ceramic foam filters were designed. To observe the flow phenomena in these systems, a water analogy experiment in a transparent plastic mold was utilized. To understand the effect of the filters used in these systems, aluminum sand casting experiments were conducted. The defect contents inside the casting samples in the outlet area of filters were measured by remelt Reduced Pressure Test (remelt RPT) and followed by measuring their bulk densities. A new “bifilm” index map, which uses the index values normalized by the metal area without porosity, was proposed. Finally, an optimized runner system with filter was suggested.

Similar content being viewed by others

References

Runyoro, J., Campbell, J., “The Running and Gating of Light Alloys,” The Foundryman, pp. 117–124 (Apr. 1992).

Campbell, J., “Castings,” p. 32, Oxford, Butterworth-Heinemann (1991).

Campbell, J., “The 10 Casting Rules: Guidelines for the Reliable Production of Reliable Castings; A Draft Process Specification, 1st Intl. Conference on Gating, Filling and Feeding of Aluminum Castings,” American Foundry Society (AFS), Oct. 11–13, 1999, pp. 35–48 (1999).

Green, N.R., Campbell, J., “Statistical Distributions of Fracture Strengths of Cast Al-7Si-Mg,” Materials Science and Engineering, vol. A173, pp. 261–266 (1993).

Sirrell, B., Campbell, J., “Mechanism of Filtration in Reduction of Casting Defects Due to Surface Turbulence during Mold Filling,” AFS Transactions, vol. 105, pp. 645–654 (1997).

Hashemi, H., Raiszadeh, R., “Naturally-Pressurized Running Systems: The Role of Ceramic Filters,” Journal of Applied Sciences, vol. 9, issue 11, pp. 2115–2122 (2009).

Gebelin, J.-C., Jolly, M.R., “Modelling Filters in Light Alloy Casting Processes (or “What Really Happens When Aluminium Flows Through a Filter”),” AFS Transactions, vol. 110, pp. 109–119 (2002).

Hsu, F.-Y., Lin, H.-J., “Foam Filters Used in Gravity Casting,” Metallurgical and Materials Transactions B, vol. 42, issue 6, pp. 1110–1117 (2011).

Din, T., Kendrick, R., Campbell, J., “Direct Filtration of A356 Alloy,” AFS Transactions, vol. 111, pp. 91–100 (2003).

Campbell, J., “Castings,” 2nd ed., Elsevier Science (May 29, 2003).

Dispinar, D., Campbell, J., “Shape Casting: 2nd International Symposium” Edited by Paul N. Crepeau, Murat Tiryakio-lu and John Campbell TMS (The Minerals, Metals & Materials Society), pp. 11–18 (2007).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hsu, FY., Li, CL. Runner Systems Containing Ceramic Foam Filters Quantified by “Area Normalized” Bifilm Index Map. Inter Metalcast 9, 23–35 (2015). https://doi.org/10.1007/BF03355620

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355620