Abstract

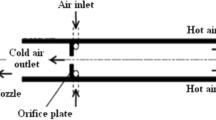

The vortex tube is a device which bifurcates the compressed gas into the cold and hot stream and is used as a flow separator. The shape of the hot outlet throttle influences the quality of cold outlet fluid in terms of temperature. This investigation focuses on the optimization of vortex tubes with three different models for throttle valves, namely conical, square, and truncated. ANSYS FLUENT software has been used to simulate flow, considering air as a working fluid for a steady-state, three-dimensional, axisymmetric, counter flow vortex tube. The standard k-ε turbulent model has been considered for the flow simulation. The effect of the shape of the control valve, intake pressure on temperature, and velocity flow has been studied. The truncated shape control valve shows a promising result for thermal performance enhancement among all the geometries considered. The coefficient of performance (COP) of a truncated control valve is highest compared to other models. The computational result of the present study has been validated with experimental data.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- VT:

-

Vortex tube

- ∆Th:

-

Hot temperature gradient, K

- Ts:

-

Static temperature, K

- dc:

-

Diameter of cold exit, mm

- ρ:

-

fluid density, kg/m3

- ∆Tc:

-

Cold temperature gradient, K

- k:

-

Thermal conductivity of intake fluid (W/mK)

- D:

-

Diameter of main tube, mm

- Z:

-

Distance between chambers

- L:

-

Length of vortex tube, mm

- ṁc:

-

Mass flow rate at cold exit, kg/s

- µc:

-

Cold mass fraction

- ṁin:

-

Mass flow rate at inlet, kg/s

- γ:

-

Specific heat ratio

- Cp:

-

Specific heat of fluid, J/kgK

References

Joseph RG, GIRATION DES FLUIDES SARL (1934) Method and apparatus for obtaining from alpha fluid under pressure two currents of fluids at different temperatures. U.S. Patent 1,952,281

Skye HM, Nellis GF, Klein SA (2006) Comparison of CFD analysis to empirical data in a commercial vortex tube. Int J Refrig 29(1):71–80

Ahlborn B, Camire J, Keller JU (1996) Low-pressure vortex tubes. J Phys D Appl Phys 29(6):1469

Aljuwayhel NF, Nellis GF, Klein SA (2005) Parametric and internal study of the vortex tube using a CFD model. Int J Refrig 28(3):442–450

Khazaei H, Teymourtash AR, Malek-Jafarian M (2012) Effects of gas properties and geometrical parameters on performance of a vortex tube. Scientia Iranica 19(3):454–462

Farouk T, Farouk B (2007) Large eddy simulations of the flow field and temperature separation in the Ranque-Hilsch vortex tube. Int J Heat Mass Transf 50(23–24):4724–4735

Pourmahmoud N, Zadeh AH, Moutaby O, Bramo A (2012) Computational fluid dynamics analysis of helical nozzles effects on the energy separation in a vortex tube. Therm Sci 16(1):151–166

Rafiee SE, Rahimi M (2013) Experimental study and three-dimensional (3D) computational fluid dynamics (CFD) analysis on the effect of the convergence ratio, pressure inlet and number of nozzle intake on vortex tube performance—validation and CFD optimization. Energy 63:195–204

Behera U, Paul PJ, Kasthurirengan S, Karunanithi R, Ram SN, Dinesh K, Jacob S (2005) CFD analysis and experimental investigations towards optimizing the parameters of Ranque-Hilsch vortex tube. Int J Heat Mass Transf 48:1961–1973

Dincer K, Baskaya S, Uysal BZ, Ucgul I (2009) Experimental investigation of the performance of a Ranque-Hilsch vortex tube with regard to a plug located at the hot outlet. Int J Refrig 32(1):87–94

Lewins J, Bejan A (1999) Vortex tube optimization theory. Energy 24(11):931–943

Kumar A, Subudhi S (2017) Cooling and dehumidification using vortex tube. Appl Therm Eng 122:181–193

Thakare HR, Parekh AD (2020) Experimental investigation of Ranque-Hilsch vortex tube and techno–economical evaluation of its industrial utility. Appl Therm Eng 169:114934

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Singh, R.K., Mahato, A., Pramanick, A.K., Rana, S.C. (2024). Study of the Impact of Flow Valve Design on the Temperature Separation in the Vortex Tube with Computational Approach. In: Singh, K.M., Dutta, S., Subudhi, S., Singh, N.K. (eds) Fluid Mechanics and Fluid Power, Volume 3. FMFP 2022. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-99-6343-0_50

Download citation

DOI: https://doi.org/10.1007/978-981-99-6343-0_50

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-6342-3

Online ISBN: 978-981-99-6343-0

eBook Packages: EngineeringEngineering (R0)