Abstract

Superelasticity is the ability of a plastically deformed solid to spontaneously recover its shape upon unloading due to stress loading. From its discovery in Au–Cd alloys in 1932, superelasticity had been believed to be limited to certain alloys until the discovery of “organic superelasticity” in 2014, which revealed it to be a general phenomenon observed in organic crystals along with ferroelasticity—reversible plastic deformability that is not accompanied by spontaneous shape recovery. In this chapter, we will introduce the discovery of organic superelasticity and the shape-memory effect, discuss superelasticity and ferroelasticity, and explain the properties and characteristics of various molecular crystals, including metal complexes. Furthermore, “organic superplasticity”—irreversible plastic deformation of several hundred percent or more, accompanied by the retention of crystallinity—has also been described.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In this chapter, we will focus on mechanically soft crystals, in which the crystal-outline change is induced by very weak mechanical stimuli. Crystal deformation is well known in atomic solids, such as gold. However, unlike atomic solids and polycrystals, single crystals—especially molecular single crystals composed of strongly anisotropic organic molecules—exhibit anisotropic deformability. Although the optical, electric, and magnetic functionalities of molecular crystals, which are related to their electronic states, have been actively studied, their mechanical properties have not received much attention because molecular crystals are generally low in their solid-state stabilities and they are fragile and easily collapsible [1].

Recently, many examples of mechanical responses to external stimuli, such as bending and twisting in response to mechanical force, heat, or light, have been reported [2]; however, they have not been fully understood. In contrast, “strict deformability”, whereby single crystals retain their nature before and after deformation, seems to be advantageous for a rapid and rigorous understanding of solid deformation and its mechanism. Therefore, we will also review the developments in “strictly deformable” superelasticity, ferroelasticity, and superplasticity in organic single crystals.

2 Organic Superelasticity and Shape-Memory Effects

In general, when an external force is applied to a solid, it undergoes elastic deformation with spontaneous reversibility, and at a certain threshold, reaches irreversible deformation such as a permanent strain or fracture due to plastic deformation (Fig. 6.1a). The strain due to elastic deformation is usually 0.1–0.2% for metals and alloys. The ability of a deformed solid to spontaneously and elastically return to its original shape is called superelasticity. Specifically, superelasticity emerges based on plastic deformation without the diffusion of atoms and molecules in a crystal lattice and significant reversible deformation beyond the elastic limit. Superelasticity was discovered in Au–Cd alloys in 1932 [3] and later observed in Cu–Zn alloys (brass) in 1938 [4]. The stress–strain curves for superelasticity are characterized by a unique hysteresis and a nearly constant stress value in the plastic-deformation region (Fig. 6.1b). In contrast, a non-diffusive plastic deformation that exhibits a spontaneous strain for a spontaneous shape recovery is called “ferroelasticity”—a ferric property [5]. In ferroelastic materials, a large deformation equivalent to that in superelastic materials is possible; however, shape recovery requires loading in a direction opposite to that of deformation (Fig. 6.1c). Shape recovery, if induced by temperature, appears as a shape-memory phenomenon (temperature-induced phase transition) with respect to the initial shape (Fig. 6.1d). In 1951, the shape-memory effect was first observed in a Au–Cd alloy [6], and its applications were extensively studied, until a TiNi alloy with a good shape-memory effect was discovered [7]. The reversible strain in TiNi alloys is approximately 11% and that in copper-based shape-memory alloys is approximately 20%. Shape-memory alloys have been used in a wide range of applications such as temperature sensors, actuators, eyeglass frames, and orthodontic wires [8]. The increasing prominence of shape-memory alloys has popularized the shape-memory effect.

Superelasticity and shape-memory effects had been believed to be unique to certain alloys until 2014, when superelasticity was observed in a single crystal of terephthalamide (TPA)—a simple aromatic organic compound—and named “organic superelasticity” [9]. As shown in Fig. 6.2, the TPA crystal was sheared and deformed and, upon unloading, spontaneously returned to its original shape. The phenomenon was a non-diffusive solid-state deformation accompanied by a single-crystal-to-single-crystal structural transition, whereby the relative positions of molecules were maintained during the formation and disappearance of new crystal domains, and the molecular-arrangement transformation and crystal deformation were strictly coordinated. Subsequent active searches for organic superelastic crystals led to the discovery of a series of organic crystals exhibiting superelasticity, including fatty acids, bulky cyclic molecules, urea derivatives, fluorescent molecules, organic salts, and even single crystals of one-dimensional coordination polymer complexes, in addition to simple aromatic organic compounds such as TPA (Fig. 6.3). As of 2022, organic superelastic crystals are no longer rare. Incidentally, the shape-memory effect of polymers is known to be similar to that of alloys in terms of shape recovery with temperature change; however, it employs glass transition and has a different mechanism from the shape-memory effect of alloys, which is based on crystal-structure transformation [10]. Therefore, shape-memory alloys and polymers have different temperature dependence of the shape-recovery force and speed, besides functional differences such as biocompatibility and conductivity.

A schematic representation of the experimental setup with face indices and snap shots of the superelastic behavior of a tetraphthalamine (TPA) crystal. Reprinted with permission from ref. [9]

2.1 Phase-Transition-Type Organic Superelasticity

As described in the previous section, TPA crystals were the first organic crystals found to exhibit superelasticity. When thin plate-like crystals with thicknesses <100 μm were sheared, they were observed to bend and spontaneously recover with the unloading of the shear force (Fig. 6.4). The stress–strain curves during deformation showed typical superelastic hysteresis curves, and the deformation and reverse-deformation stresses during shape recovery were 0.496 and 0.456 MPa, respectively. Surprisingly, the superelasticity of the TPA single crystal was almost unchanged in the first and hundredth cycles, indicating high stability (Fig. 6.4a). Incidentally, for superelastic materials such as TiNi alloys, pre-use mechanical training is essential, because the superelastic properties change significantly over the first few tens of cycles.

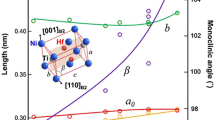

a Single-cycle and 100-cycle (inset) results of the stress–strain curves for superelasticity; b [001-]α and [010]α projection views. C: Gray; H: white; N: blue; O: red. Reprinted with permission from ref. [9]

To clarify the detailed mechanism of superelastic deformation, X-ray crystal structural analysis was performed using a crystal in the bent state (two-phase coexisting state) as a twin crystal. The phase transition is believed to have been caused by mechanical forces as well as superelasticity, based on the martensitic transformation known for alloys, and the Gibbs-energy difference between the α and β phases is believed to have driven the spontaneous shape recovery. Essentially, the stress-induced phase β is unstable at room temperature and spontaneously transitions to the stable α phase by eliminating stress. The difference in the crystal structures of the α and β phases suggests a molecular orientation change during the stress-induced phase transition (Fig. 6.4b). In superelastic crystals, the cooperative motion of molecules in restricted molecular motion induces the bulk shape change. Such molecular motion in soft crystals is interesting (although difficult to define objectively).

Not only have aromatic-compound crystals been found to be superelastic but also fatty-acid crystals with long-chain alkyl groups (Fig. 6.5), and detailed deformation properties of pentadecanoic acid (PDA) have revealed that superelasticity is based on a stress-induced phase transition from the high-temperature (A′) to the low-temperature (B′) phase [11]. As the Gibbs-energy difference is the driving force for the spontaneous shape recovery corresponding to superelasticity during deformation at a certain temperature, the material exhibits superelasticity above that temperature. In contrast, near the phase-transition temperature, no reverse deformation occurred and the A′h and B′ phases stably coexisted, indicating a ferroelastic deformation. Heating the crystals increased the Gibbs-energy difference, and the B′ phase transitioned to the A'h phase, resulting in the shape-memory effect. Fatty acids are biocompatible and are also found in foods, and may lead to the development of materials that solve the existing problems of shape-memory alloys, such as the toxicity of Ni.

a Chemical formula of aliphatic acids: n = 13; pentadecanoic acid (PDA). b Superelastic behavior of a PDA crystal, c estimated movement of PDA during superelastic behavior, and d Gibbs-energy diagram explaining the interchange between A′h and B′ phases with classifications of ferroelasticity (FE), shape-memory effect (SME), and superelasticity (SE). Reprinted with permission from ref. [11]

2.2 Twin-Crystal-Type Organic Superelasticity

The next superelastic example is 3,5-difluorobenzoic acid (FBA) crystals [12]. FBA is a derivative of benzoic acid with fluorine atoms substituted at the 3 and 5 positions, and its crystal structure belongs to the 21/c space group. Columnar FBA crystals obtained via sublimation, when sheared, bent at approximately 27°, producing a stress-induced daughter (α1) phase from the parent (α0) phase, and spontaneously recovered their shape upon stress relief (Fig. 6.6). The stress–strain curve at the time showed a typical hysteresis curve of superelasticity, as in the case of shape-memory alloys and TPA crystals (Fig. 6.6). The deformation and reverse-deformation stresses during shape recovery were 0.07 and 0.02 MPa, respectively, which were significantly low, ranging from 1/7 to 1/23 times those of the TPA crystal.

Reproduced with permission from ref. [12]

a Chemical structure of 3,5-difluorobenzoic acid (FBA), b superelastic deformation of FBA, c stress–strain curve of deformation, d face indices of a mechanically twinned FBA crystal, and e possible molecular movement during twinning.

The deformation of the FBA crystals was investigated in detail via X-ray crystallography and was found to be attributable to mechanical twinning, unlike that of TPA crystals, which was based on stress-induced phase transition. This difference in the deformation-stress mechanisms is considered to be responsible for the large difference in the deformation stresses. In twins with identical crystal structures, the Gibbs energies are equal under similar conditions. Therefore, in the superelastic spontaneous shape recovery, the reverse transformation from the α1 phase to the α0 phase is expected to have a driving force other than the Gibbs-energy difference. Currently, the driving force is believed to be the strain accumulated by the twin-interface distortion and elastic deformation, but further investigation is necessary to elucidate the mechanism.

2.3 Organosuperelastic Crystals Exhibiting Luminescent Chromism

2-(2′-Hydroxyphenyl)imidazo[1,2-a]pyridine (HPIP) shows a large Stokes-shift emission (ESIPT emission) due to photoirradiation-induced intramolecular charge separation caused by an excited-state proton transfer. Mutai et al. have previously reported crystal-polymorph-dependent ESIPT luminescence in HPIP and its derivatives [13]. Superelasticity was discovered in the luminiscent 7-chloro-2-(2′-hydroxyphpenyl)imidazo[1,2-a]pyridine (7Cl) (Fig. 6.3) crystals with intramolecular hydrogen bonding. The yellow-green luminescent crystal phase (αYG) of 7Cl exhibited superelasticity [14]. A yellow-orange luminescent crystal phase (αYO) was generated via phase transition induced by mechanical loading and spontaneously recovered to the original αYG phase after unloading (Figs. 6.7a and 7b). The appearance of each crystalline phase was revealed via X-ray structural analysis, and the face index of the crystalline-phase interface was (120)YG//(120)YO (or (120)YG//(120) YO). The calculated value of the bending angle (42.1°) was consistent with the value measured microscopically (42°). The bending angles of the crystalline phases during the transition from Y to YO, the 68-degree (or 61-degree and 16-degree) rotation of the 7Cl molecules, and their further mutation by 2.0 and 1.9 Å suggested an optimized herringbone-type arrangement (Fig. 6.7c). This mechanochromic luminescence mechanism is based on superelasticity (plastic deformation without diffusion and spontaneous shape recovery), which allows reversible, stepless, and instantaneous control over the two-color emission ratio via a single-crystal-to-single-crystal phase transition by controlling a single stimulus: stress [14].

a Snapshots of superelastic deformation of a YG crystal under UV light (365 nm) (scale bar: 100 μm). b Schematic representation of superelastic deformation and c estimated molecular correspondence at the αYG//βYO interface in a deformed YG crystal based on X-ray results. Reprinted with permission from ref. [14]

2.4 Superelasticity in Metal-Complex Crystals

Metal complexes combine the excellent designability of organic molecules with the excellent electronic properties of metal atoms. In particular, coordination polymers with porous structures are expected to be useful for gas adsorption and other applications, based on the uptake of guest molecules. Mechanical twinning-based superelasticity was observed in one such type of porous coordination polymer, the {Cu2(bza)4(pyz)}n (bza = benzoate, pyz = pyradine; CuBP) crystal (Fig. 6.3) [15], which exhibits gas permeability along the channel direction. Interestingly, they succeeded in reversibly converting the channel direction into a nearly orthogonal direction via mechanical twinning followed by superplasticity (Fig. 6.8). Such a single-crystal–gas-permeable film, with a controllable channel structure achieved via mechanical force, is a good example of the effective use of structural changes accompanied by superelasticity.

a Growth of a 5-µm-wide band from the pushed edge of the (1–1-1) crystal surface at room temperature. b Connection of the mother (α) and daughter (α′) crystal phases at 298 K accompanied by the rotation of the channel direction (green bands) under the twinned state at a bending angle of 14.6° along the projected direction of [010]α and [010]α′, based on crystallography. c The regulation of the α′ crystal domains sandwiched by the pushing positions as a shear on {1–1-1}α. d The experimental system. e Active generation/degeneration of the daughter-crystal domains by shearing the microcrystal of 1 (0.48 × 0.17 × 0.10 mm3) with movable needles and f the directions of the penetrating channels. Reprinted with permission from ref. [15]

2.5 Shape-Memory Effect

Next, we focus on the shape-memory effect in organic crystals. In the search for organic superelastic materials, tetrabutyl-n-phosphonium tetraphenylborate (BPPB) crystals were found to exhibit strong elastic, superelastic, and shape-memory effects (Fig. 6.9) [16]. When columnar BPPB crystals, obtained via recrystallization from acetone, were sheared at room temperature, they bent at approximately 12°, while generating a daughter (α−) phase from the mother (α+) phase, and maintained this shape after stress relieving. Upon heating, the crystals transitioned to the high-temperature (β) phase at approximately 125 ℃, yielding a linearly layered phase. When cooled to approximately 122 ℃, the crystalline phase became linear—containing only the α+ phase—via a bending state, wherein it coexisted with the α− phase. Essentially, it exhibited the shape-memory effect (Fig. 6.9b). The crystals exhibited superelasticity due to stress-induced phase transition at approximately 125 ℃, where the high-temperature phase was stable and the deformation and reverse-deformation stresses increased with the temperature (Fig. 6.9c), which was similar to the temperature dependence of the superelasticity of alloys. Although organic crystals are recognized to be brittle and fragile, these shape-memory effects and the increase in the shape recovery with temperature proved that even a small crystal, with a width and thickness of 0.6 and 0.3 cm, respectively, can bear >100 g of weight (Fig. 6.9d). The BPPB crystals also proved that superelasticity can be achieved in multicomponent organic crystals such as organic salts, co-crystals, and inclusion compounds, indicating the possibility of tuning superelastic properties by changing the combinations of molecules.

Reproduced with permission from ref. [16]

a The chemical structure of tetrabutyl-n-phosphonium tetraphenylborate (BPPB), b shape-memory effect in BPPB, c temperature-dependent stress–strain curves, and d mechanical work using the shape-memory effect of a BPPB crystal.

3 Organic Ferroelasticity

Ferroelasticity is a non-diffusive plastic deformation that shows spontaneous strain and is characterized by hysteresis of symmetric stress–strain curves. Despite being extensively studied in inorganic crystals, owing to its tractability and functionality, ferroelasticity was first reported in the organic squaric acid crystals [17]. In 2017, ferroelastic deformation and the corresponding hysteresis curves were observed for 5-chloro-2-nitoroaniline (CNA) crystals, and the molecular deformation mechanism was elucidated via X-ray crystallography [18]. Systematic investigation revealed ferroelasticity to be a relatively common phenomenon even in organic crystals, which are considered to be brittle and fragile. X-ray crystallographic analyses also revealed ring rotation, conformational change of alkyl chains, and flipping of cyclohexane rings, which reflect the molecular structure of crystals. 1,4-Diethoxybenzene (EB) crystals exhibited deformation due to zone-multiple twinning, which constituted continuous mechanical twinning around the zone axis [19]. Thus, strains many times higher than those attainable via single mechanical twinning deformation were achieved (Fig. 6.10). Such free deformability, accompanied by the retention of the crystalline nature of single crystals, is unique. As described previously, ferroelasticity is an attractive property in the formation of organic crystals, because it allows permanent strain beyond the elastic limit while maintaining crystallinity. The energy-dissipation property of ferroelasticity is also expected to be useful in vibration absorption.

Ferroelastically deformed 1,4-diethoxybenzene (EB). Reprinted with permission from ref. [19]

4 Coexistence of Organic Superelasticity and Ferroelasticity

Superelasticity shows spontaneous shape recovery, whereas ferroelasticity shows spontaneous strain (permanent strain). Therefore, they are regarded as properties with opposing mechanical responses. The shape-memory effect can be achieved by switching these two properties via thermal phase transition. If these two properties can be made to coexist under identical conditions, organic crystals can be made to exhibit superelasticity in multiple directions, depending on the shape deformed by a ferroelastic forming process. Multidirectional superelasticity can create organic crystalline materials with free-deformation superelasticity, such as shape-memory alloys. Here, as examples of coexistence of organic superelasticity and ferroelasticity, we will describe a superelastic–ferroelastic transformation process and a shear-direction-selective expression of superelasticity and ferroelasticity.

4.1 Shape Remembrance and Antiferroelasticity of Organic Crystals Via Superelastic–Ferroelastic Conversion

1,4-Dicyanobenzene (DCB) crystals show superelasticity due to mechanical twinning (Fig. 6.11) [20], even though they do not have a conformationally changeable site like FBA, as described in Sect. 6–2-2. The superelasticity of DCB is attributable to rotational twinning at 180°, as in FBA crystals, but the actual motion during the deformation was elucidated to be an orientational change of only 5–7°, rather than the rotation of the entire molecule by 180°. Interestingly, by holding the DCB crystal in the bent shape for a long time, the mechanical properties of the bent region were found to gradually change as superelastic → ferroelastic → superelastic, and the crystal became uniaxially superelastic in two directions, positive and negative (Fig. 6.11). The shape of the stress–strain hysteresis curve of such uniaxial bidirectional superelasticity resembles that of the electric-field-polarization hysteresis curve of antiferroelectric materials, indicating antiferroelasticity proposed by Aizu in 1969 [21]. In the case of shape remembrance (rewriting) from a straight shape to a bent shape via memory processing, a processing time ≥300 h was required before antiferroelasticity was exhibited. At a higher temperature of 50 °C, the processing time was shortened, and antiferroelasticity was observed after approximately 200 h. While returning the flexural shape to the original linear system, shape remembrance progressed 60–200 times faster than the flexural shape memory. In contrast to the shape-memory treatment of shape-memory alloys, which requires heating to several hundred degrees Celsius or higher, DCB crystals can be treated at <100 °C. Although DCB crystals have a low thermal stability and sublimate at high temperatures, the thermally stable organic superelastic crystals can be processed in seconds to minutes at temperatures >100 °C. Shape remembrance has not yet been achieved in DCB crystals because of their low thermal stability. Further investigations into shape-remembrance properties and low-temperature and high-speed shape-memory processing could lead to the discovery of practical applications of organic superelastic materials.

Shape-memory processing and superelastic behavior of a DCB crystal in opposing directions (antiferroelasticity) with stress–strain curves after shape-memory processing for 0 h (black), 268 h (red), and 580 h (blue). Reprinted with permission from ref. [20]

4.2 Shear-Direction Selectivity of Superelasticity-Ferroelasticity and Multidirectional Superelastic Crystals

Metallic crystals, which are aggregates of spherical atoms, have multiple crystallographically equivalent directions and show identical responses in these directions. In contrast, organic crystals exhibit strongly anisotropic structures and functions due to the shape of their constituent molecules. Organic hyperelasticity and ferroelasticity are also caused by the anisotropic molecular motion induced by the application of shear stress to organic crystals from a specific direction, indicating the possibility of selective expression of superelasticity and ferroelasticity in single crystals depending on the loading direction.

Recently, shear-direction-dependent manifestations of superelasticity and ferroelasticity were observed in 1,3-bis(4-methoxyphenyl)urea (MPU) crystals (Fig. 6.3) [22]. Furthermore, zigzag, crankshaft, S-shaped, and U-shaped MPU crystals exhibiting multidirectional superelasticity were fabricated by subjecting MPU crystals to permanent strain via ferroelastic deformation and exploiting the coexistence of superelasticity and ferroelasticity in the unified crystals (Fig. 6.12). Each deformation was a mechanical twinning that maintained its single-crystalline and superelastic properties. Thus, each of the differently oriented single-crystalline domains was a multidirectional superelastic crystal.

Directions of superelasticity before and after ferroelastic shaping of MPU crystals. Reprinted with permission from ref. [22]

5 Organic Superplasticity

Superplasticity, originally known as a processing and forming method for metallic materials, enables the deformation of solids by more than several hundred percent via grain-boundary slip of polycrystalline bands under heating. Organic crystals, which are considered to be brittle and fragile, can also exhibit deformations of several hundred percent or more without losing their crystallinity, a phenomenon we call “organic superplasticity” [23].

The chiral and polar N,N-dimethyl-4-nitoroanilinie (MNA) crystals—having electron-withdrawing nitro groups in the para position of the electron-donating dimethylamino groups, a large dipole moment, and an achiral molecular structure despite belonging to the P21 space group—were investigated. Plate-like MNA crystals, obtained using acetone, showed superelasticity, whereby they bent at approximately 23° due to mechanical twinning via shear and spontaneously recovered their shape when the force was removed. X-ray crystallographic analysis of the bent crystals suggested that the mechanical twinning caused a change in the dihedral angle of <3° between the dimethylamino and nitro groups with respect to the benzene ring. Due to such miniscule changes, the mother (α0) and daughter (α1) phases of the twins had a crystallographic relationship of rotational symmetry at 180°. Interestingly, when a shear force was applied to the plate-like MNA crystal parallel to the (001) plane in the [100] direction, the crystal exhibited multiple slip planes and finally a shear strain of >500% (Fig. 6.13). Thus, a superplastic deformation mechanism different from that of metallic materials was found. After deformation, the crystals also showed superelasticity, indicating that the single-crystalline nature was maintained even after slip deformation. Organic superplasticity, which enables large deformation of organic crystals while maintaining their crystalline properties, can provide new formability to organic crystals and has basic and applied research prospects.

a Superelastic behavior of an MNA crystal via multilayer slipping and b the estimated molecular movement in the crystalline state. c Superelastic behavior after superplastic deformation (ε = 400%) of an MNA-crystal deformation. Reprinted with permission from ref. [23]

6 Conclusion

In this chapter, we discussed the rigorous deformability of molecular crystals via hyperelasticity, ferroelasticity, and superplasticity. Previously, organic crystals were considered to be fragile, and their mechanical properties had been largely ignored. However, intensive research has significantly advanced organic superelasticity and related theories. Recently, organic superelastic crystals have been actively developed [24]. Organic superelasticity is expected to create a variety of functional elastic materials with higher-order properties and functions than those of conventional alloys and polymers. The addition of superelasticity to the fundamental properties of materials, such as elasticity and plasticity, could lead to new developments in materials chemistry.

References

Kitaigorodskii AI (1973) Molecular crystals and molecules. Academic Press, London

(a) Naumov P, Chizhik S, Panda MK, Nath NK, Boldyreva E (2015) Chem Rev 115:12440; (b) Saha S, Mishra MK, Reddy CM, Desiraju GR (2018) Acc Chem Res 51:2957–2967; (c) Karothu DP, Mahmoud J Halabi, Ahmed E, Ferreira R, Spackman PR, Spackman MA, Naumov P (2022) Angew Chem Int Ed Engl 61:e202113988; (d) Spackman PR, Grosjean A, Thomas SP, Karothu DP, Naumov P, Spackma MA (2022) Angew Chem Int Ed Engl 61:e202110716; Koshima H, Hasebe S, Hagiwara Y, Asahi T (2021) Isr J Chem 61:683–696; Yu Q, Aguila B, Gao J, Xu P, Chen Q, Yan J, Xing D, Chen Y, Cheng P, Zhang Z, Ma S (2019) Chem Eur J 25:5611–5622

Ölander A (1932) J Am Chem Soc 4:3819

Greninger AB, Mooradian VG (1938) Trans. Metallurg. Soc. AIME 128:337

(a) Aizu K (1970) Phys Rev B 2:754

Chang C, Read TA (1951) Transactions of the AIME 189:47

Buehler WJ, Gilfrich JV, Wiley RC (1963) J Appl Phys 34:1475

(a) Otsuka K, Ren X (1999) Intermetallics 7:511; (b) Jani JM, Leary M, Subic A, Gibson MA (2014) Mater Des 56:1078

Takamizawa S, Miyamoto Y (2014) Angew Chem Int Ed 53:6970

(a) Sokolowski WM, Chmielewski AB, Hayashi A, Yamada T (1999) Proceedings of Society of Photooptical Instrucmentation Engineers (SPIE), vol 3669, p 179; (b) Lendlein A, Kelch S (2002) Angew Chmie Int Ed 41:2034; (c) Behl M, Lendlein A (2007) Mater Today 10:20

Takamizawa S, Takasaki Y (1912) Cryst Growth & Des 2019:19

Takamizawa S, Takasaki Y (2015) Angew Chem Int Ed 54:4815

(a) Mutai T, Tomoda H, Ohkawa T, Yabe Y, Araki K (2008) Angew Chem Int Ed 47:9522–9524; (b) Mutai T, Shoni H, Shigemitsu Y, Araki K (2014) CrystEngCom 16:3890–3895

Mutai T, Sasaki T, Sakamoto S, Yoshikawa I, Houjou H, Takamizawa S (1824) Nat Commun 2020:11

Takasaki Y, Takamizawa S (2015) Nat Comm 6:1–5

Takamizawa S, Takasaki Y (2016) Chem Sci 7:1527

Suzuki I, Okada K (1979) Solid State Commun 29:759–762

Mir SH, Takasaki Y, Engel ER, Takamizawa S (2017) Angew Chem Int Ed 56:15882–15885

Engel ER, Takamizawa S (2018) Angew Chem Int Ed 57:11888–11892

Sakamoto S, Sasaki T, Sato-Tomita A, Takamizawa S (2019) Angew Chem Int Ed 58:13722

Aizu K (1969) J Phys Soc Jpn 27:1171–1178

Sasaki T, Sakamoto S, Takamizawa S (2020) Angew Chem Int Ed 59:4340–4343

Takamizawa S, Takasaki Y, Sasaki T, Ozaki N (2018) Nat Comm 9:3984

Ahmed E, Karothu DP, Naumov P (2018) Angew Chem Int Ed Engl 57:8837–8846

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this chapter

Cite this chapter

Takamizawa, S., Kato, M. (2023). Elastic and Plastic Soft Crystals with Superelasticity, Ferroelasticity, and Superplasticity. In: Kato, M., Ishii, K. (eds) Soft Crystals. The Materials Research Society Series. Springer, Singapore. https://doi.org/10.1007/978-981-99-0260-6_6

Download citation

DOI: https://doi.org/10.1007/978-981-99-0260-6_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-0259-0

Online ISBN: 978-981-99-0260-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)