Abstract

Lightweight brick reduces the overall self-weight of the structures resulting in the reduction of the foundation size, cost, and other specifications. However, conventional lightweight brick production causes several environmental impacts and produces low mechanical properties, so there is a clear need to search and replace for more efficient and durable alternatives beyond the limitations of the conventional lightweight brick. Geopolymer represents an excellent opportunity to ensure greater sustainability in the construction industry especially for the use of industrial waste such as fly ash. This research focuses on the production of fly ash-based lightweight geopolymer brick using superplasticizer as a foaming agent. The effects of geopolymeric synthesis parameters such as the sodium hydroxide (NaOH) concentration (6, 8, 10, 12 and 14 M), ratio of foaming agent to water (1/10, 1/20, 1/30 and 1/40) by volume, ratio of foam to geopolymer paste (0.5, 1.0, 1.5 and 2.0) by volume, on the lightweight geopolymer paste that affect the mechanical and microstructure properties were studied in detailed. The compressive strength, water absorption and density were analyzed to determine the mechanical properties of lightweight geopolymer brick. The microstructure properties of lightweight geopolymer brick were tested by using Scanning Electron Microscope. The results indicated that the lightweight geopolymer brick has an optimum NaOH concentration of 12 M, with highest compressive strength of 15.2 MPa at 7 days, an optimum ratio of foaming agent to water (1/10) and ratio of foam to geopolymer paste (1.0) with the highest strength of 16.6 MPa (7 days). A potential new lightweight brick can be produced by using a low-cost foaming agent and easy to process for addition to geopolymer paste.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

El-Hassan H, Shao Y, Ghouleh Z (2013) Effect of initial curing on carbonation of lightweight concrete masonry units. ACI Mater J 110:441–450. https://doi.org/10.14359/51685791

ACI 213 (2010) Guide for structural lightweight-aggregate concrete reported by ACI Committee 213. ACI COMMITTEE REPORT, 1–38

Kan A, Demirboǧa R (2009) A novel material for lightweight concrete production. Cem Concr Compos 31(7):489–495. https://doi.org/10.1016/j.cemconcomp.2009.05.002

Tsaousi GM, Douni I, Taxiarchou M, Panias D, Paspaliaris I (2016) Development of foamed inorganic polymeric materials based on perlite. IOP Conf Ser Mater Sci Eng 123(1):12062. https://doi.org/10.1088/1757-899X/123/1/012062

Wongkeo W, Thongsanitgarn P, Ngamjarurojana A, Chaipanich A (2014) Compressive strength and chloride resistance of self-compacting concrete containing high level fly ash and silica fume. Mater Des 64:261–269. https://doi.org/10.1016/j.matdes.2014.07.042

Aminudin E, Md. Din MF, Hussin MW, Iwao K, Mohanadoss P, Ichikawa Y (2015) Properties of industrial boiler ash as sand replacement and thermal improvement in aerated concrete. Malaysian J Civ Eng 27(1):155–169

Awana M, Kumar C (2017) Cellular lightweight concrete. In: International conference on emerging trends in engineering, technology, sciences and management, Adithya Institute of Technology, pp 241–246

Davidovits J (1989) Geopolymers and geopolymeric materials. J Therm Anal 35:429–441. https://doi.org/10.1007/BF01904446

Wu HC, Sun P (2007) New building materials from fly ash-based lightweight inorganic polymer. Constr Build Mater 21(1):211–217. https://doi.org/10.1016/j.conbuildmat.2005.06.052

Petrillo A, Cioffi R, Ferone C, Colangelo F, Borrelli C (2016) Eco-sustainable geopolymer concrete blocks production process. Agric Agric Sci Procedia 8:408–418. https://doi.org/10.1016/j.aaspro.2016.02.037

Hajimohammadi A, Ngo T, Mendis P (2017) How does aluminium foaming agent impact the geopolymer formation mechanism? Cem Concr Compos 80:277–286. https://doi.org/10.1016/j.cemconcomp.2017.03.022

Arshad MS, Pawade PY (2014) Reuse of natural waste material for making lightweight bricks. Int J Sci Technol Res 3(6):49–53

Mineral Products association (2013) Brick and block production. Mortar Ind Assoc Learn Texts 05(20):1–10

Kadir AA, Mohajerani A, Roddick F, Buckeridge J (2009) Density, strength, thermal conductivity and leachate characteristics of lightweight fired clay bricks incorporating cigarette butts. World Acad Sci Eng Technol 53(5):179–184

Ahmari S, Zhang L (2012) Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr Build Mater 29:323–331. https://doi.org/10.1016/j.conbuildmat.2011.10.048

Zhang L (2013) Production of bricks from waste materials—a review. Constr Build Mater 47:643–655. https://doi.org/10.1016/j.conbuildmat.2013.05.043

Murekar NR, Satpute RS, Chaudhari MM (2017) Using waste material for making light weight bricks. In: International conference on recent trends in engineering sciences and technology (ICRTEST 2017). pp 467–470

Komnitsas K, Zaharaki D (2007) Geopolymerisation: a review and prospects for the minerals industry. Miner Eng 20(14):1261–1277. https://doi.org/10.1016/j.mineng.2007.07.011

Deboucha S, Hashim R (2011) A review on bricks and stabilized compressed earth blocks. Sci Res Essays 6(3):499–506. https://doi.org/10.5897/SRE09.356

Haider W (2007) In-plane response of wide spaced reinforced masonry shear walls. Dissertation, Central Queensland University, Queensland

Ling IH, Teo DCL (2012) Compressive strength and durability properties of lightweight concrete bricks under full water curing and air-dry curing. Int J Sustain Energy Dev 1, pp 14–20. https://doi.org/10.20533/ijsed.2046.3707.2012.0003

Kumar R, Patyal V, Lallotra B, Kumar D, Brick C (2014) Study of properties of light weight fly ash. Int J Eng Res Appl (IJERA) 49–53

Balamurugan G, Chockalingam K, Chidambaram M, Aravindha kumar M, Balasundaram M (2017) Experimental study on light weight foamed concrete. Int Res J Eng Technol 4(4):677–686

Mahendran K, Sivaram T, Shahulhameed MRL (2016) A comparative study on various building blocks as an alternative to conventional bricks. In: International conference on emerging trends in engineering and management research (ICETEMR-16). pp 1097–1109

Siram KKB (2012) Cellular light-weight concrete blocks as a replacement of burnt clay bricks. Int J Eng Adv Technol 2(2):149–151

Xu Y, Jiang L, Xu J, Li Y (2012) Mechanical properties of expanded polystyrene lightweight aggregate concrete and brick. Constr Build Mater 27(1):32–38. https://doi.org/10.1016/j.conbuildmat.2011.08.030

Li X, Ma X, Zhang S, Zheng E (2013) Mechanical properties and microstructure of class C fly ash-based geopolymer paste and mortar. Materials (Basel) 6(4):1485–1495. https://doi.org/10.3390/ma6041485

Bakharev T (2006) Thermal behaviour of geopolymers prepared using class F fly ash and elevated temperature curing. Cem Concr Res 36(6):1134–1147. https://doi.org/10.1016/j.cemconres.2006.03.022

Zhuang XY, Chen L, Komarneni S, Zhou CH, Tong DS, Yang HM, Yu WH, Wang H (2016) Fly ash-based geopolymer: clean production, properties and applications. J Clean Prod 125:253–267. https://doi.org/10.1016/j.jclepro.2016.03.019

Duxson P, Provis JL, Lukey GC, Mallicoat SW, Kriven WM, Van Deventer JSJ (2005) Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf Physicochem Eng Asp 269:47–58. https://doi.org/10.1016/j.colsurfa.2005.06.060

Saidi N, Samet B, Baklouti S (2013) Effect of composition on structure and mechanical properties of metakaolin based PSS-Geopolymer. Int J Mater Sci 3(4):145. https://doi.org/10.14355/ijmsci.2013.0304.03

Davidovits PJ (2002) 30 years of successes and failures in geopolymer applications. Market trends and potential breakthroughs. In: Geopolymer 2002 Conference. pp 1–16

Chindaprasirt P, Chareerat T, Hatanaka S, Cao T (2010) High-strength geopolymer using fine high-calcium fly ash. J Mater Civ Eng 23:246–271. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000161

Duxson P, Mallicoat SW, Lukey GC, Kriven WM, van Deventer JSJ (2007) The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf Phys Eng Asp 292(1):8–20. https://doi.org/10.1016/j.colsurfa.2006.05.044

Xu H, Van Deventer JSJ (2000) The geopolymerisation of alumino-silicate minerals. Int J Miner Process 59(3):247–266. https://doi.org/10.1016/S0301-7516(99)00074-5

Hardjito D, Cheak CC, Lee Ing CH (2009) Strength and setting times of low calcium fly ash-based geopolymer mortar. Mod Appl Sci 2(4):2–11. https://doi.org/10.5539/mas.v2n4p3

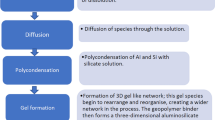

Fernández-Jiménez A, Palomo A, Criado M (2005) Microstructure development of alkali-activated fly ash cement: a descriptive model. Cem Concr Res 35(6):1204–1209. https://doi.org/10.1016/j.cemconres.2004.08.021

Skvara F, Šulc R, Tišler Z, Skricik P, Šmilauer V, Zlámalová Cílová Z (2014) Preparation and properties of fly ash-based geopolymer foams. Ceram Silikaty 58(3):188–197

Nyale SM, Babajide OO, Birch GD, Böke N, Petrik LF (2013) Synthesis and characterization of coal fly ash-based foamed geopolymer. Procedia Environ Sci 18:722–730. https://doi.org/10.1016/j.proenv.2013.04.098

Memon FA, Nuruddin MF, Khan S, Shafiq N, Ayub T (2013) Effect of sodium hydroxide concentration on fresh properties and compressive strength of self-compacting geopolymer concrete. J Eng Sci Technol 8(1):44–56

Rattanasak U, Chindaprasirt P (2009) Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner Eng 22(12):1073–1078. https://doi.org/10.1016/j.mineng.2009.03.022

Hanjitsuwan S, Hunpratub S, Thongbai P, Maensiri S, Sata V, Chindaprasirt P (2014) Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem Concr Compos 45:9–14. https://doi.org/10.1016/j.cemconcomp.2013.09.012

Hardjito D (2005) Studies on fly ash-based geopolymer concrete. Dissertation, Petra Christian University

Brooks R, Bahadory M, Tovia F, Rostami H (2010) Properties of alkali-activated fly ash: high performance to lightweight. Int J Sustain Eng 3(3):211–218. https://doi.org/10.1080/19397038.2010.487162

Liu Z, Shao NN, Qin JF, Kong FL, Wang CX, Wang DM (2015) Strength and thermal behavior of low weight foam geopolymer using circulating fluidized bed combustion fly ash. J Cent South Univ 22(9):3633–3640. https://doi.org/10.1007/s11771-015-2904-0

Kargin A, Baev V, Mashkin N (2017) Fly-ash geo-polymer foamed concrete. In: AIP conference proceedings, p 020005

Feng J, Zhang R, Gong L, Li Y, Cao W, Cheng X (2015) Development of porous fly ash-based geopolymer with low thermal conductivity. Mater Des 65:529–533. https://doi.org/10.1016/j.matdes.2014.09.024

Yang T, Chou C, Chien C (2012) The effects of foaming agents and modifiers on a foamed-geopolymer. In: The world congress on advances in civil, environmental and materials research (ACEM), pp 905–914

Kallunkal G, John E (2016) Optimization of foam concrete masonry blocks. Int J Eng Res Gen Sci 4(5):85–106

Ryu GS, Lee YB, Koh KT, Chung YS (2013) The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr Build Mater 47:409–418. https://doi.org/10.1016/j.conbuildmat.2013.05.069

Pavithra P, Srinivasula Reddy M, Dinakar P, Hanumantha Rao B, Satpathy BK, Mohanty AN (2016) Effect of the Na2SiO3/NaOH ratio and NaOH molarity on the synthesis of fly ash-based geopolymer mortar. Geo-Chicago 2016:336–344

Chindaprasirt P, Jaturapitakkul C, Chalee W, Rattanasak U (2009) Comparative study on the characteristics of fly ash and bottom ash geopolymers. Waste Manag 29(2):539–543. https://doi.org/10.1016/j.wasman.2008.06.023

Huseien GF, Ismail M, Khalid NHA, Hussin MW, Mirza J (2018) Compressive strength and microstructure of assorted wastes incorporated geopolymer mortars: Effect of solution molarity. Alexandra Eng J 57(4):3375–3386. https://doi.org/10.1016/j.aej.2018.07.011

Zhang Z, Provis JL, Reid A, Wang H (2014) Geopolymer foam concrete: an emerging material for sustainable construction. Constr Build Mater 56:113–127. https://doi.org/10.1016/j.conbuildmat.2014.01.081

Somna K, Jaturapitakkul C, Kajitvichyanukul P, Chindaprasirt P (2011) NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 90(6):2118–2124. https://doi.org/10.1016/j.fuel.2011.01.018

Jitchaiyaphum K, Sinsiri T, Chindaprasirt P (2011) Cellular lightweight concrete containing pozzolan materials. Procedia Eng 14(2):241–246. https://doi.org/10.1016/j.proeng.2011.07.145

Abdullah MMAB, Jamaludin L, Hussin K, Bnhussain M, Ghazali CMR, Ahmad MI (2012) Fly ash porous material using geopolymerization process for high temperature exposure. Int J Mol Sci 13(12):4388–4395. https://doi.org/10.3390/ijms13044388

Görhan G, Kürklü G (2014) The influence of the NaOH solution on the properties of the fly ash-based geopolymer mortar cured at different temperatures. Compos Part B Eng 58:371–377. https://doi.org/10.1016/j.compositesb.2013.10.082

Bashar II, Alengaram UJ, Jumaat MZ, Islam A (2014) The effect of variation of molarity of alkali activator and fine aggregate content on the compressive strength of the fly ash: palm oil fuel ash based geopolymer mortar. Adv Mater Sci Eng 2014:1–13. https://doi.org/10.1155/2014/245473

Nyale S, Babajide O, Birch G, Boke N (2015) The influence of NaOH and NaOCl on the characteristics of fly ash-based foamed geopolymer. In: Proceedings of the 14th international conference on environmental science and technology (CEST2015)

Bakkali H, Ammari M, Frar I (2016) NaOH alkali-activated class F fly ash: NaOH molarity, curing conditions and mass ratio effect. J Mater Environ Sci 7(2):397–401

Abdullah MAB, Kamarudin H, Norazian MN, Ruzaidi CM, Zarina Y (2013) Microstructure studies on the effect of the alkaline activators ratio in preparation of fly ash-based geopolymer. In: International conference on chemistry and chemical process (IPCBEE), pp 13–17

Risdanareni P, Hilmi A, Susanto PB (2017) The effect of foaming agent doses on lightweight geopolymer concrete metakaolin based. In: The 3rd ISM international statistical conference, p 020057

Liu MYJ, Alengaram UJ, Jumaat MZ, Mo KH (2014) Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build 72:238–245. https://doi.org/10.1016/j.enbuild.2013.12.029

Zhao Y, Ye J, Lu X, Liu M, Lin Y, Gong W, Ning G (2010) Preparation of sintered foam materials by alkali-activated coal fly ash. J Hazard Mater 174:108–112. https://doi.org/10.1016/j.jhazmat.2009.09.023

Masi G, Rickard WDA, Vickers L, Bignozzi MC, Van Riessen A (2014) A comparison between different foaming methods for the synthesis of light weight geopolymers. Ceram Int 40:13891–13902. https://doi.org/10.1016/j.ceramint.2014.05.108

Cilla MS, Colombo P, Morelli MR (2014) Geopolymer foams by gelcasting. Ceram Int 40(4):5723–5730. https://doi.org/10.1016/j.ceramint.2013.11.011

American Society for Testing and Materials (ASTM) (2012) Standard specification for concrete building brick. The USA. ASTM C55–12, West Conshohocken

American Society for Testing and Materials (ASTM) (2011) Standard specification for non-load bearing concrete masonry units 1. The USA. ASTM C129–11, West Conshohocken

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ibrahim, W.M.W., Abdullah, M.M.A.B., Hussin, K., Kadir, A.A., Ahmad, R. (2021). Technological Properties of Fly Ash-Based Lightweight Geopolymer Brick. In: Abdul Kadir, A., Amira Sarani, N., Shahidan, S. (eds) Sustainable Waste Utilization in Bricks, Concrete, and Cementitious Materials. Lecture Notes in Civil Engineering, vol 129. Springer, Singapore. https://doi.org/10.1007/978-981-33-4918-6_3

Download citation

DOI: https://doi.org/10.1007/978-981-33-4918-6_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4917-9

Online ISBN: 978-981-33-4918-6

eBook Packages: EngineeringEngineering (R0)