Abstract

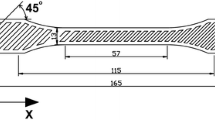

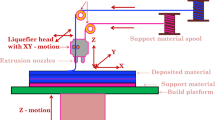

In this paper, fused deposition modeling (FDM) parts are characterized for flexural behavior using an experimental and numerical investigation. Flexural test was conducted using ASTM D790 standard to find the flexural strength and modulus. Tensile test and compression test were conducted using ASTM D638 and ASTM D695, respectively, to evaluate the mechanical properties. Finite element (FE) model using classical laminate theory was developed by considering a few build parameters of FDM. Flexural test condition was simulated using the elastic properties obtained from experiments based on CLT approach with orthotropic and isotropic material model. The results showed that the computational model built using classical laminate theory was well correlated with the experiments as compared to that of isotropic model for the same loading condition.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Saravana Kumar, G., Kalra, P.K., Dhande, S.G.: Direct layered manufacturing of point sampled objects. Int. J. Manuf. Technol. Manag 6(6), 534–549 (2004)

Bellini, A., Güçeri, S.: Mechanical characterization of parts fabricated using fused deposition modeling. Rapid Prototyp. J. 9(4), 252–264 (2003)

Alaimo, G., Marconi, S., Costato, L., Auricchio, F.: Influence of meso-structure and chemical composition on FDM 3D-printedparts. Compos. B Eng. 113, 371–380 (2017)

Casavola, C., Cazzato, A., Moramarco, V., Pappalettere, C.: Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater. Des. 90, 453–458 (2016)

Somireddy, M., Czekanski, A.: Mechanical characterization of additively manufactured parts by FE modeling of mesostructure. J. Manuf. Mater. Process. 1(2), 18 (2017)

Dawoud, M., Taha, I., Ebeid, S.J.: Mechanical behaviour of ABS: an experimental study using FDM and injection moulding techniques. J. Manuf. Process. 21, 39–45 (2016)

Velivela, V., Saravana Kumar, G.: A finite element model to predict the part strength of fused deposition modeling printed parts. In: International Mechanical Engineering Congress and Exposition, ASME, Phoenix, USA (2016)

Gokulakrishnan, J., Saravana Kumar, G.: Optimum adaptive slicing considering the layer strength of fused deposition modelling parts. In: International Conference on Engineering Optimization, pp. 442–452. Springer, Cham, Lisbon, Portugal (2018)

Jothibabu, G., Saravana Kumar, G.: Surrogate based sensitivity analysis of part strength due to process parameters in fused deposition modelling. Proced. Comput. Sci 133, 772–778 (2018)

Jones, R.M.: Mechanics of composite materials, 2nd edn. CRC Press, USA (1999)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gokulakrishnan, J., Saravana Kumar, G. (2020). Experimental and Numerical Investigation of the Flexural Behavior of Fused Deposition Modeling Parts. In: Shunmugam, M., Kanthababu, M. (eds) Advances in Additive Manufacturing and Joining. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-32-9433-2_31

Download citation

DOI: https://doi.org/10.1007/978-981-32-9433-2_31

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-32-9432-5

Online ISBN: 978-981-32-9433-2

eBook Packages: EngineeringEngineering (R0)