Abstract

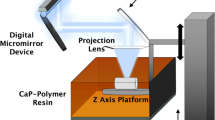

Additive manufacturing (AM) is a disruptive technology that brings a paradigm shift in design and manufacturing by facilitating the fabrication of new-to-market, mass-customized and more innovative products. AM is primarily different from conventional manufacturing as it allows the building of a structure using a layer-by-layer approach from a digital model. In the traditional manufacturing route, the product is made first, followed by its appreciation of novelty and its sale to the customer. However, AM disrupts the conventional pathway by understanding the feel first through digitization, then selling the product and finally making it. Realizing the potential and importance of AM, a comprehensive R&D program has been undertaken since 2003 at Raja Ramanna Center for Advanced Technology (RRCAT) India. The present chapter introduces AM, followed by AM’s various freedoms, limitations, need and evolution, and the global scenario. It includes the classification of AM as per ASTM/ ISO 52900 and how AM contributes toward Industry 4.0. It also discusses the development of indigenous AM technology and its deployment for various applications at RRCAT, along with the future scope of the technology.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

C.P. Paul, A.N. Jinoop, S.K. Nayak, A.C. Paul, Laser additive manufacturing in industry 4.0: Overview, applications, and scenario in developing economies, in Additive Manufacturing Applications for Metals and Composites, ed. K.R. Balasubramanian, V. Senthilkumar (IGI Global, Hershey, PA, 2020), pp. 271–295

International Organization for Standardization—American Society for Testing and Materials International, ISO/ASTM 52900:2015(en) Additive manufacturing—General principles—Terminology (2015)

I. Gibson, D.W. Rosen, B. Stucker, in Additive Manufacturing Technologies 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing (Second). (Springer, New York, NY, 2015). Retrieved from http://lib.ugent.be/catalog/ebk01:2670000000006827

C.P. Paul, A.N. Jinoop, K.S. Bindra, Metal Additive Manufacturing using Lasers, in Additive Manufacturing Applications and Innovations (First. ed. by R. Singh, J.P. Davium (CRC Press, Boca Raton, 2018), pp.37–94

A.J. Pinkerton, [INVITED] Lasers in additive manufacturing. Optics & Laser Tech. 78, 25–32 (2016). https://doi.org/10.1016/j.optlastec.2015.09.025

S. Yadav, A.N. Jinoop, N. Sinha, C.P. Paul, K.S. Bindra, Parametric investigation and characterization of laser directed energy deposited copper-nickel graded layers. Int. J. Adv. Manuf. Tech. 108(11), 3779–3791 (2020). https://doi.org/10.1007/s00170-020-05644-9

L.D. Bobbio, B. Bocklund, R. Otis, J.P. Borgonia, R.P. Dillon, A. Shapiro, et al., Characterization of a functionally graded material of Ti-6Al-4V to 304L stainless steel with an intermediate V section. J. Alloys Comp. 742, 1031–1036 (2018). https://doi.org/10.1016/j.jallcom.2018.01.156

C.P. Paul, Parametric Studies of Laser Metal Deposition for Fabrication Engineer-ing Components (Devi Ahilya Vishwavidyalaya, Indore, India, 2005)

R. Liu, Z. Wang, T. Sparks, F. Liou, J. Newkirk, 13–Aerospace applications of laser additive manufacturing, in Woodhead Publishing Series in Electronic and Optical Materials, ed. M.B.T.-L.A.M. Brandt (Woodhead Publishing, 2017), pp. 351–371. https://doi.org/10.1016/B978-0-08-100433-3.00013-0

S.K. Malyala, Y. Ravi Kumar, L. Kankanala, P. Vasamsetty, A. Alwala, Assessment and treatment planning in maxillofacial surgery by using additive manufacturing technology. Mat. Today: Proc. 5(2, Part 1), 4162–4166 (2018). https://doi.org/10.1016/j.matpr.2017.11.678

M. Binder, L. Kirchbichler, C. Seidel, C. Anstaett, G. Schlick, G. Reinhart, Design concepts for the integration of electronic components into metal laser-based powder bed fusion parts. Procedia CIRP 81, 992–997 (2019). https://doi.org/10.1016/j.procir.2019.03.240

B.E. Carroll, T.A. Palmer, A.M. Beese, Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mat. 87, 309–320 (2015). https://doi.org/10.1016/j.actamat.2014.12.054

N.S. Hmeidat, R.C. Pack, S.J. Talley, R.B. Moore, B.G. Compton, Mechanical anisotropy in polymer composites produced by material extrusion additive manufacturing. Additive Manuf. 34, 101385 (2020). https://doi.org/10.1016/j.addma.2020.101385

T. Wohlers, T. Gornet, Wohlers Report 2016 (2016)

Royal Academy of Engineering, Additive manufacturing: opportunities and constraints (2013)

N.A. Chartrain, C.B. Williams, A.R. Whittington, A review on fabricating tissue scaffolds using vat photopolymerization. Acta Biomat. 74, 90–111 (2018). https://doi.org/10.1016/j.actbio.2018.05.010

P. Gay, D. Blanco, F. Pelayo, A. Noriega, P. Fernández, Analysis of factors influencing the mechanical properties of flat PolyJet manufactured parts 132, 70–77 (2015). https://doi.org/10.1016/j.proeng.2015.12.481

I. Rishmawi, M. Salarian, M. Vlasea, Tailoring green and sintered density of pure iron parts using binder jetting additive manufacturing. Additive Manuf. 24, 508–520 (2018). https://doi.org/10.1016/j.addma.2018.10.015

C.L. Cramer, P. Nandwana, J. Yan, S.F. Evans, A.M. Elliott, C. Chinnasamy, M.P. Paranthaman, Binder jet additive manufacturing method to fabricate near net shape crack-free highly dense Fe-6.5 wt.% Si soft magnets. Heliyon 5(11), e02804 (2019). https://doi.org/10.1016/j.heliyon.2019.e02804

A. Bournias-Varotsis, R.J. Friel, R.A. Harris, D.S. Engstrøm, Ultrasonic additive manufacturing as a form-then-bond process for embedding electronic circuitry into a metal matrix. J. Manuf. Proc. 32, 664–675 (2018). https://doi.org/10.1016/j.jmapro.2018.03.027

S.K. Nayak, S.K. Mishra, C.P. Paul, A.N. Jinoop, K.S. Bindra, Effect of energy density on laser powder bed fusion built single tracks and thin wall structures with 100 µm preplaced powder layer thickness. Optics & Laser Tech. 125, 106016 (2020). https://doi.org/10.1016/j.optlastec.2019.106016

P.J. Mosterman, J. Zander, Industry 4.0 as a cyber-physical system study. Software & Systems Model. 15(1), 17–29 (2016). https://doi.org/10.1007/s10270-015-0493-x

Acknowledgements

The authors express their sincere gratitude to Mr. Debashis Das, Director RRCAT, for his constant support and encouragement. Thanks to Mr. S. V. Nakhe, Director—Laser Group, and Dr. K. S. Bindra, Associate Director—Laser Group, for constant encouragement in this evolving program at RRCAT. The authors are also thankful to our collaborators and colleagues at Laser Additive Manufacturing Laboratory for their support. A N Jinoop acknowledges the financial support of RRCAT, Department of Atomic Energy, Government of India, and HBNI, Mumbai.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Paul, C.P., Jinoop, A.N. (2023). Additive Manufacturing: Bringing a Paradigm Shift. In: Shrivastava, A., Arora, A., Srivastava, C., Dhawan, N., Shekhar Singh, S. (eds) New Horizons in Metallurgy, Materials and Manufacturing. Indian Institute of Metals Series. Springer, Singapore. https://doi.org/10.1007/978-981-19-5570-9_3

Download citation

DOI: https://doi.org/10.1007/978-981-19-5570-9_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5569-3

Online ISBN: 978-981-19-5570-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)