Abstract

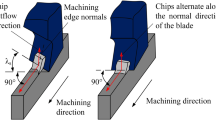

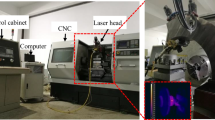

Ceramic matrix composites (CMCs) have high strength and good corrosion resistance and are widely used in aerospace and other fields. However, it is not easy to achieve high-quality machining by traditional processing methods. Laser-assisted machining (LAM) is one of the commonly used machining methods for difficult-to-process materials. This paper takes C/SiC composites as the object to conduct an experimental study on laser-assisted micromachining (LAMM). The influence of fibre orientation (parallel fibres, transverse fibres and across fibres) on the machining performance of C/SiC composites was mainly studied and compared with conventional machining (CM). The experimental results show that, under the same cutting parameters, the surface quality obtained by LAMM is better than that obtained by CM, the surface roughness Ra value is reduced, and the micro-defects of the machined surface are significantly reduced. The change in laser power has a significant effect on the surface quality. LAMM can effectively improve the surface quality of C/SiC composites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zhang, L.T., Cheng, L.F., Xu, Y.D.: Progress in research work of new CMC-SiC. Aeronaut. Manuf. Technol. 1, 24–33 (2003)

Yu, H., Zhou, X., Wei, Z., Peng, H., Zhang, C.: Mechanical behavior of SiCf/SiC composites with alternating PyC/SiC multilayer interphases. Mater. Design 44, 320–324 (2013)

Yuan, W., Wu, H.: Microstructure of friction surface developed on carbon fibre reinforced carbon–silicon carbide (Cf/C–SiC). J. Eur. Ceram. Soc. 32(12), 3509–3519 (2012)

Krenkel, W., Berndt, F.: C/C–SiC composites for space applications and advanced friction systems. Mater. Sci. Eng., A 412, 177–181 (2005)

Wang, J., Cheng, L.F., Liu, Y.S., Liu, X.Y., Zhang, Q.: Research development on processing technology of silicon carbide ceramic matrix composites. Aeronaut. Manuf. Technol. 510(15), 50–56 (2016)

Diaz, O.G., Luna, G.G., Liao, Z., Axinte, D.: The new challenges of machining ceramic matrix composites (CMCs): review of surface integrity. Int. J. Mach. Tools Manuf. 139, 24–36 (2019)

Banika, S.R., Kalitab, N., Gajranic, K.K., Kumarc, R., Sankar, M.R.: Recent trends in laser assisted machining of ceramic materials. Mater. Today Proc. 5(9), 18459–18467 (2018)

Kannan, V., Radhakrishnan, R., Palaniyandi, K.: A review on conventional and laser assisted machining of aluminium based metal matrix composites. Eng Rev 34(2), 75–84 (2014)

König, W., Cronjäger, L., Spur, G., Tönshoff, H.K., Zdeblick, W.J.: Machining of new materials. CIRP Ann. Manuf. Technol. 39(2), 673–681 (1990)

Rozzi, J.C., Pfefferkorn, F.E., Shin, Y.C.: Experimental evaluation of the laser assisted machining of silicon nitride ceramics. J. Heat Transfer 122(4), 666–670 (2000)

Wang, Y., Yuan, Z.J., Guo, L.X., Wei, S.X.: The study on the surface properties after laser assisted cutting for ZrO2 ceramic. Appl. Laser 20(1), 10–13 (2000)

Zhai, C.T., et al.: The study on surface integrity on laser-assisted turning of SiCp/2024Al. Int. J. Optomechatronics 14(1), 29–43 (2020)

Park, C.I., Wei, Y., Hassani, M., Jin, X., Park, S.S.: Low power direct laser-assisted machining of carbon fibre-reinforced polymer. Manuf. Lett. 22, 19–24 (2019)

Acknowledgments

The project is supported by National Natural Foundation of China (Number U19A20103).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zhai, C., Xu, J., Hou, Y., Chen, G., Sun, G. (2022). Study on Surface Quality of C/SiC Ceramic Composites in Laser-Assisted Micromachining. In: Yang, S., Luo, X., Yan, Y., Jiang, Z. (eds) Proceedings of the 7th International Conference on Nanomanufacturing (nanoMan2021). nanoMan 2021. Smart Innovation, Systems and Technologies, vol 296. Springer, Singapore. https://doi.org/10.1007/978-981-19-1918-3_11

Download citation

DOI: https://doi.org/10.1007/978-981-19-1918-3_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1917-6

Online ISBN: 978-981-19-1918-3

eBook Packages: EngineeringEngineering (R0)