Abstract

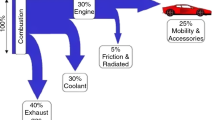

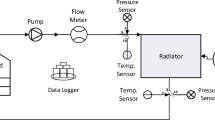

In this paper, we will analyze all aspects of graphite foam for cooling in heat exchanger. The primary purpose of an automobile’s cooling system is to keep the engine cool and in good working order without overheating or overcooling it. Overheating the engine will result in the melting of engine parts and, eventually, the engine seizing. And, in the event of engine overcooling, the whole engine system will shut down. The advanced cooling system was achieved by using carbon foam as the fin material for radiator construction, then replacing the ordinary centrifugal pump with a sliding vane rotary pump, and finally using nanofluids as coolants in the radiator. We will improve the cooling performance of the engine as well as the mechanical efficiency of the engine by applying these three methodologies.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Klett JW (2000) Process for making carbon foam, US Patent 6033506

Yu Q, Thompson BE, Straatman AG (2006) A unit cube-based model for heat transfer and fluid flow in porous carbon foam. J Heat Transfer 128:352–360

Straatman AG, Gallego NC, Thompson BE, Hangan H (2006) Thermal characterization of porous carbon foam—convection in parallel flow. Int J Heat Mass Transfer 49:1991–1998

Klett J, Hardy R, Romine E, Walls C, Burchell T (2000) High-thermal conductivity, mescophase-pitch-derived carbon foams: effect of precursor on structure and properties. Carbon 38:953–973

Paek WJ, Kang HB, Kim YS, Hyum MJ (2000) Effective thermal conductivity and permeability of aluminum foam materials. Int J Thermophys 21(2):453–464

Klett J, Ott R, McMillan A (2000) Heat exchangers for heavy vehicles utilizing high thermal conductivity graphite foams, SAE paper 2000–01–2207

Yu Q, Straatman AG, Thompson BE (2006) Carbon-foam finned tubes in air-water heat exchangers. Appl Therm Eng 26:131–143

Garrity PT, Klausner JF, Mei R (2010) Performance of aluminum and carbon foams for air side heat transfer augmentation. J Heat Transfer 132(121901):1–10

Straatman AG, Gallego NC, Yu Q, Thompson BE (2007) Characterization of porous carbon foam as a material for compact recuperators. J Eng Gas Turbines Power 129:326–330

Gallego NG, Klett JW (2003) Carbon foams for thermal management. Carbon 41:1461–1466

Leong KC, Jin LW, Li HY, Chai JC (2008) Forced convection air cooling in porous graphite foam for thermal management applications. In: 11th intersociety conference on thermal and thermomechanical phenomena in electronic systems, pp 57–64

Lin YR, Du JH, Wu W, Chow LC, Notardonato W (2010) Experimental study on heat transfer and pressure drop of recuperative heat exchangers using carbon foam. J Heat Transfer 132(091902):1–10

Yuan J, Huang Y, Sundén B, Wang W (2009) Analysis of parameter effects on chemical reaction coupled transport phenomena in SOFC anodes. Heat Mass Transfer 45:471–484

Lu W, Zhao CY, Tassou SA (2006) Thermal analysis on metal-foam filled heat exchangers. Part I: metal-foam filled pipes. Int J Heat Mass Transf 49:2751–2761

Pope SB (2000) Turbulent flows. Cambridge University, UK

Versteeg HK, Malalasekera W (2007) An introduction to computational fluid dynamics, 2nd edn. Pearson Prentice Hall, UK

Chang Y, Wang C (1997) A generalized heat transfer correlation for louver fin geometry. Int J Heat Mass Transf 40:533–544

Chang Y, Hsu K, Lin Y, Wang C (2000) A generalized friction correlation for louver fin geometry. Int J Heat Mass Transf 43:2237–2243

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Rajput, K., Roy, N.K., Martin, A.C. (2023). Advanced Cooling System Using Graphite Foam Heat Exchangers for Automobile. In: Yadav, S., Jain, P.K., Kankar, P.K., Shrivastava, Y. (eds) Advances in Mechanical and Energy Technology. ICMET 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-1618-2_13

Download citation

DOI: https://doi.org/10.1007/978-981-19-1618-2_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1617-5

Online ISBN: 978-981-19-1618-2

eBook Packages: EngineeringEngineering (R0)