Abstract

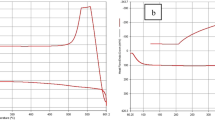

Computer-aided cooling curve analysis (CA-CCA) is a cost-saving and easy-to-use thermal analysis tool to identify the solidification characteristics of a material. This paper aims to present the relationship between cooling rate and solidification parameters of aluminum–silicon alloy before semisolid metal processing. An induction furnace was used to melt the as-prepared specimen by heating the respective graphite crucible to 680 ℃ and left it to be cooled and solidified under three different cooling rate conditions. A double thermocouple method was employed by placing one K-type thermocouple at the crucible center and another one near to the crucible wall. Both thermocouple sensors were connected to a data acquisition device, NI 9219 which was linked to a computer with DASYLab pre-installed inside for data logging, along with OriginPro 2019b for graphical representation. Low, intermediate, and high cooling rate conditions were achieved when the crucible was cooled with its top and bottom surface enclosed with Fiberfrax felt (1.0 ℃/s), at ambient temperature (1.3 ℃/s), and by a compressed air flow supplied from air compressor (1.9 ℃/s), respectively. The increase in cooling rate facilitates the nucleation rate and the growth of crystals within the alloy system and thus leads to a shorter solidification time with all the critical points highlighting the phase transition are shifted accordingly.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

ASM International Handbook Committee, ASM handbook volume 2: properties and selection—nonferrous alloys and special-purpose materials

Kaufman JG, Rooy EL (2004) Aluminum alloy castings: properties, processes, and applications. https://doi.org/10.1017/CBO9781107415324.004

Nafisi S, Ghomashchi R (2016) Semi-solid processing of aluminum alloys. Springer International Publishing, Cham. https://doi.org/10.1007/978-3-319-40335-9

Spencer DB, Mehrabian R, Flemings MC (1972) Rheological behavior of Sn-15 pct Pb in the crystallization range. Metall Trans 3(7):1925–1932. https://doi.org/10.1007/BF02642580

Alexandrou AN, Burgos GR, Entov VM (2000) Semisolid metal processing: a new paradigm in automotive part design. SAE Tech Pap 724. https://doi.org/10.4271/2000-01-0676

Hu XG, Zhu Q, Midson SP et al (2017) Blistering in semi-solid die casting of aluminium alloys and its avoidance. Acta Mater 124:446–455. https://doi.org/10.1016/j.actamat.2016.11.032

Salleh MS, Omar MZ, Syarif J, Mohammed MN (2013) An overview of semisolid processing of aluminium alloys. ISRN Mater Sci 2013:1–9. https://doi.org/10.1155/2013/679820

Omar MZ, Atkinson HV, Palmiere EJ, Howe AA, Kapranos P (2004) Microstructural development of HP9/4/30 steel during partial remelting. Steel Res Int 75(8–9):552–560. https://doi.org/10.1002/srin.200405810

Mohammed MN, Omar MZ, Salleh MS, Alhawari KS, Kapranos P (2013) Semisolid metal processing techniques for nondendritic feedstock production. Sci World J 2013:16. https://doi.org/10.1155/2013/752175

Ahmad AH, Naher S, Aqida SN, Brabazon D (2014) Routes to spheroidal starting material for semisolid metal processing. Compr Mater Process 5:135–148. https://doi.org/10.1016/B978-0-08-096532-1.00515-X

Pola A, Tocci M, Kapranos P (2018) Microstructure and properties of semi-solid aluminum alloys: a literature review. Metals (Basel) 8(3). https://doi.org/10.3390/met8030181

Miller WS, Zhuang L, Bottema J et al (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng A 280(1):37–49. https://doi.org/10.1016/S0921-5093(99)00653-X

Liu D, Atkinson HV, Kapranos P, Jirattiticharoean W, Jones H (2003) Microstructural evolution and tensile mechanical properties of thixoformed high performance aluminium alloys. Mater Sci Eng A 361(1–2):213–224. https://doi.org/10.1016/S0921-5093(03)00528-8

Ihsan-Ul-Haq, Shin JS, Lee ZH (2004) Computer-aided cooling curve analysis of A356 aluminum alloy. Met Mater Int 10(1):89–96. https://doi.org/10.1007/BF03027368

Husain NH, Ahmad AH, Rashidi MM (2020) Thermal analysis of 6061 wrought aluminium alloy using cooling curve analysis-computer aided (CCA-CA) method. IOP Conf Ser Mater Sci Eng 788(1). https://doi.org/10.1088/1757-899X/788/1/012018

Sudheer R, Prabhu KN (2016) A computer aided cooling curve analysis method to study phase change materials for thermal energy storage applications. Mater Des 95:198–203. https://doi.org/10.1016/j.matdes.2016.01.053

Koke J, Modigell M (2003) Flow behaviour of semi-solid metal alloys. J Nonnewton Fluid Mech 112(2–3):141–160. https://doi.org/10.1016/S0377-0257(03)00080-6

Fan Z (2002) Semisolid metal processing. Int Mater Rev 47(2):49–86. https://doi.org/10.1179/095066001225001076

Modigell M, Koke J (2001) Rheological modelling on semi-solid metal alloys and simulation of thixocasting processes. J Mater Process Technol 111(1–3):53–58. https://doi.org/10.1016/S0924-0136(01)00496-4

Flemings MC (1991) Behavior of metal alloys in the semisolid state. Metall Trans A 22(5):957–981. https://doi.org/10.1007/BF02661090

Hirt G, Kopp R (2009) Thixoforming: semi-solid metal processing, p 454

Backerud L, Chai G, Tamminen J (1990) Solidification characteristics of aluminum alloys. Found Alloy 2:2

Farahany S, Ourdjini A (2013) Effect of cooling rate and silicon refiner/modifier on solidification pathways of Al–11.3Si–2Cu–0.4Fe alloy. Mater Manuf Process 28(6):657–663. https://doi.org/10.1080/10426914.2013.763972

Rosso M (2012) Thixocasting and rheocasting technologies, improvements going on. J Achiev Mater Manuf Eng 54(1):110–119

Marchwica P, Microstructual and thermal analysis of AlSi and MgAl alloys subjected to high cooling rates. Electronic theses and dissertations

Veldman NLM, Dahle AK, Stjohn DH, Arnberg L (2001) Dendrite coherency of Al–Si–Cu alloys. Metall Mater Trans A Phys Metall Mater Sci 32(1). https://doi.org/10.1007/s11661-001-0110-1

Acknowledgements

The authors would like to be obliged to the Ministry of Higher Education for providing financial support under Fundamental Research Grant Scheme (FRGS) No. FRGS/1/2019/TK03/UMP/03/4 (University reference RDU1901166) and Universiti Malaysia Pahang for laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ma, X.H., Abd Razak, N.A. (2023). The Change of Solidification Parameters on Hypoeutectic Aluminum–Silicon Alloy Under Different Cooling Rates. In: Ismail, M.Y., Mohd Sani, M.S., Kumarasamy, S., Hamidi, M.A., Shaari, M.S. (eds) Technological Advancement in Mechanical and Automotive Engineering. ICMER 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-1457-7_21

Download citation

DOI: https://doi.org/10.1007/978-981-19-1457-7_21

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1456-0

Online ISBN: 978-981-19-1457-7

eBook Packages: EngineeringEngineering (R0)