Abstract

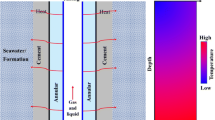

The high-pressure and low-temperature environment prevailing in the process of offshore oil and gas development is very prone to the formation of hydrate in the wellbore to block the tubing, which leads to production reduction and shutdown and causes a series of production accidents. Current mainstream hydrate prevention and treatment methods have the disadvantages of high cost, high toxicity and high pollution, and new and more effective hydrate prevention and treatment methods are urgently needed in the deep-water offshore well development. In this paper, the thermal effect of cavitation is introduced into the hydrate prevention and treatment process of deep-water offshore production wells, and the upper section of the completion tubing structure is designed to be applicable to the actual field. With the help of indoor experimental system, we have analyzed the influences of several working parameters such as the injection pressure, injection frequency, initial temperature of the fluid and the pressure inside the cavitator on the development of cavitation thermal effect. Preliminary conclusion drawn from both numerical simulation and experimental observations provides a new and possible way of natural gas hydrate prevention in near future.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Sloan, E.D.: A changing hydrate paradigm-from apprehension to avoidance to risk management. Fluid Phase Equilib. 228–229, 67–74 (2005)

Guo, Y.L., Sun, B.J., Zhao, K.K., et al.: A prediction method of natural gas hydrate formation in deepwater gas wells and its application. Petroleum 2(3), 296–300 (2016)

Creek, J.L.: Efficient hydrate plug prevention. Energy Fuels 26, 4112–4116 (2012)

Xu, P., Lang, X., Fan, S., et al.: Molecular dynamics simulation of methane hydrate growth in the presence of the natural product pectin. J. Phys. Chem. C 120(10), 5392–5397 (2016)

Xu, X.H.: Experimental study on the feasibility of natural gas hydrate injection heat extraction. China University of Petroleum (East China), Qingdao (2014)

Zhao, X., Qiu, Z.S., Huang, W.A., et al.: Mechanism of action of thermodynamic inhibitors of natural gas hydrates and optimal design. ACTA Petrolei Sinica 36(6), 760–766 (2015)

Sa, J.H., Kwak, G.H., Han, K., et al.: Gas hydrate inhibition by perturbation of liquid water structure. Sci. Rep. 5(1), 1–9 (2015)

Yan, K.F., Li, X.S., Chen, Z.Y., et al.: Molecular dynamics simulation of the crystal nucleation and growth behavior of methane hydrate in the presence of the surface and nanopores of porous sediment. Langmuir 32(31), 7975–7984 (2016)

Pan, S.S., Peng, X.S.: Mechanisms of Cavitation. National Defense Industry Press, Beijing (2013)

Cai, J., Huai, X.L., Liu, B., et al.: Applications of Liquid Cavitation Technology. Science Press, Beijing (2019)

Zheng, X.: Study of sub-Bjerknes force between two bubbles under the action of acoustic field. Shaanxi Normal University, Xi’an (2016)

Kong, W.D.: Research on hydrocavitation-enhanced chlorine dioxide degradation of phenol wastewater. North Central University, Taiyuan (2017)

Huang, J.T.: Principles and Applications of Cavitation and Cavitation. Tsinghua University Press, Beijing (1991)

Luo, X.W., Ji, B., Peng, X.X.: Theory and Applications of Cavitation. Tsinghua University Press, Beijing (2020)

Tomita, Y., Shima, A.: On the behavior of a spherical bubble and the impulse pressure in a viscous compressible liquid. Bull. Jpn. Soc. Mech. Eng. 20(149), 1453–1460 (1977)

Fujikawa, S., Akamatsu, T.: Effects of the non-equilibrium condensation of vapor on the pressure wave produced by the collapse of a bubble in a liquid. J. Fluid Mech. 97(3), 481–512 (1980)

Suslick, K.S., Hammerton, D.A.: Sonochemical hot spot. J. Am. Chem. Soc. 89(18), 5641–5645 (1986)

Kim, D.J., Sung, H.J., Choi, C.H., et al.: Cavitation instabilities during the development testing of a liquid oxygen pump. J. Propul. Power 33(1), 187–192 (2017)

Kikuta, K., Yoshida, Y., Watanabe, M., et al.: Thermodynamic effect on cavitation performance and cavitation instabilities in an inducer. J. Fluids Eng.-Trans. ASME 130(11), 111302 (2008)

Tong, D.S.: Research on cavitation jet treatment technology for oilfield produced water. China University of Petroleum (East China), Qingdao (2009)

Fu, J.S., Li, G.S., Shi, H.Z., et al.: A novel tool to improve the rate of penetration-hydraulic-pulsed cavitating-jet generator. SPE Drill. Complet. 27(3), 355–362 (2012)

Melyanyuk, M.V., Akhlyan, I.A.: Technological application of cavitating jet streams in the oil and gas industry. Neftyanoe Khozyaystvo-Oil Industry 11, 130–133 (2019)

Li, H.X.: Experimental study on ultrasonic cavitation anti-scaling and hydraulic cavitation anti-scaling and enhanced heat transfer. Graduate School of Chinese Academy of Sciences (Institute of Engineering Thermophysics), Beijing (2009)

Lu, Y.Y., Ding, H., Ge, Z.L., et al.: Experimental study on the influence of thermal effect of cavitation water jet on coal permeability. Rock Soil Mech. 35(5), 1247–1254 (2014)

Ming, X.L.: Oxidative deterioration effect of cavitation heat generation on hydraulic oil. IEEE Access 19(9), 11–21 (2020)

Yu, B.: Hydraulic cavitation performance enhancement and its application research. Jiangsu University, Zhenjiang (2014)

Kim, J., Song, S.J.: Measurement of temperature effects on cavitation in a turbopump inducer. J. Fluids Eng. 138(1), 011304 (2016)

Qiu, J.J.: Experimental study of thermal effect of fluid cavitation. China University of Petroleum (East China), Qingdao (2018)

Wang, M.B., Qiu, J.J., Chen, W.Q.: Towards the development of cavitation technology for gas hydrate prevention. R. Soc. Open Sci. 8, 202054 (2021)

Ohl, C.D., Arora, M.: Surface cleaning from laser-induced cavitation bubbles. Appl. Phys. Lett. 89(7), 102–103 (2006)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wang, Mb., Wang, W., Wang, Rl. (2022). A New Method for the Prevention of Natural Gas Hydrate During Transportation and Production. In: Sun, B., Sun, J., Wang, Z., Chen, L., Chen, M. (eds) Proceedings of The Fourth International Technical Symposium on Deepwater Oil and Gas Engineering. DWOG-Hyd 2021. Lecture Notes in Civil Engineering, vol 246. Springer, Singapore. https://doi.org/10.1007/978-981-19-0960-3_28

Download citation

DOI: https://doi.org/10.1007/978-981-19-0960-3_28

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-0959-7

Online ISBN: 978-981-19-0960-3

eBook Packages: EngineeringEngineering (R0)