Abstract

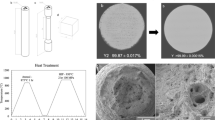

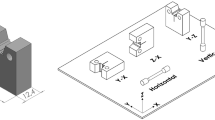

The paper presents tensile tests and Charpy tests of Ti6Al4V samples made with different build orientations in a laser powder bed fusion process. Seven different build orientations from 0° to 90° were tested. The test specimens were heat treated at 850 ℃. Fracture surfaces were investigated with SEM. The materials showed a high degree of isotropy when measuring yield strength, tensile strength and elastic modulus. Elongation measurements indicated some degree of anisotropy, but not statistically significant. A similar trend was found in Charpy impact energy. Pores, microstructure and melt pool boundaries were investigated to explain the obtained results. The impact of pores was found to be insignificant. Melt pool boundaries and columnar prior-β grains are not a significant factor in the anisotropic trends observed. The anisotropy in mechanical properties was found to be caused by microstructure and/or crystallographic texture.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Buirette, C., Huez, J., Gey, N., Vassel, A., Andrieu, E.: Study of crack propagation mechanisms during Charpy impact toughness tests on both equiaxed and lamellar microstructures of Ti–6Al–4V titanium alloy. Mater. Sci. Eng. A. 618, 546–557 (2014)

Gong, H., Rafi, K., Gu, H., Ram, G.J., Starr, T., Stucker, B.: Influence of defects on mechanical properties of Ti–6Al–4 V components produced by selective laser melting and electron beam melting. Mater. Des. 86, 545–554 (2015)

Hartunian, P., Eshraghi, M.: Effect of build orientation on the microstructure and mechanical properties of selective laser-melted Ti-6Al-4V alloy. J. Manuf. Mater. Proces. 2(4), 69 (2018)

Kasperovich, G., Haubrich, J., Gussone, J., Requena, G.: Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 105, 160–170 (2016)

Kumar, P., Prakash, O., Ramamurty, U.: Micro-and meso-structures and their influence on mechanical properties of selectively laser melted Ti-6Al-4V. Acta Mater. 154, 246–260 (2018)

Kurishita, H., Kayano, H., Narui, M., Yamazaki, M., Kano, Y., Shibahara, I.: Effects of V-notch dimensions on Charpy impact test results for differently sized miniature specimens of ferritic steel. Mater. Trans. JIM 34(11), 1042–1052 (1993)

Lütjering, G., Williams, J.C.: Titanium. Springer, Heidelberg (2007)

Shifeng, W., Shuai, L., Qingsong, W., Yan, C., Sheng, Z., Yusheng, S.: Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 214(11), 2660–2667 (2014)

Stef, J., Poulon-Quintin, A., Redjaimia, A., Ghanbaja, J., Ferry, O., De Sousa, M., et al.: Mechanism of porosity formation and influence on mechanical properties in selective laser melting of Ti-6Al-4V parts. Mater. Des. 156, 480–493 (2018)

Thijs, L., Verhaeghe, F., Craeghs, T., Van Humbeeck, J., Kruth, J.-P.: A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 58(9), 3303–3312 (2010)

Vilaro, T., Colin, C., Bartout, J.-D.: As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A. 42(10), 3190–3199 (2011)

Voisin, T., Calta, N.P., Khairallah, S.A., Forien, J.-B., Balogh, L., Cunningham, R.W., et al.: Defects-dictated tensile properties of selective laser melted Ti-6Al-4V. Mater. Des. 158, 113–126 (2018)

Wu, M.-W., Lai, P.-H., Chen, J.-K.: Anisotropy in the impact toughness of selective laser melted Ti-6Al-4V alloy. Mater. Sci. Eng. A. 650, 295-299 (2016)

Xu, W., Lui, E.W., Pateras, A., Qian, M., Brandt, M.: In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 125, 390–400 (2017)

Yang, J., Yu, H., Wang, Z., Zeng, X.: Effect of crystallographic orientation on mechanical anisotropy of selective laser melted Ti-6Al-4V alloy. Mater. Charact. 127, 137–145 (2017)

Yang, J., Yu, H., Yin, J., Gao, M., Wang, Z., Zeng, X.: Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 108, 308–318 (2016)

Yasa, E., Deckers, J., Kruth, J.-P., Rombouts, M., Luyten, J.: Charpy impact testing of metallic selective laser melting parts. Virtual Phys. Prototyping 5(2), 89–98 (2010)

Zhang, X.-Y., Fang, G., Leeflang, S., Böttger, A.J., Zadpoor, A.A., Zhou, J.: Effect of subtransus heat treatment on the microstructure and mechanical properties of additively manufactured Ti-6Al-4V alloy. J. Alloy. Compd. 735, 1562–1575 (2018)

Acknowledgment

The authors thank the Interreg Sweden-Norway programme for supporting this work through the TROJAM project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Nes, E.V., Hovig, E.W., Feitosa, L., Sørby, K. (2022). Effect of Building Orientation in Mechanical Properties of Ti6Al4V Produced with Laser Powder Bed Fusion. In: Wang, Y., Martinsen, K., Yu, T., Wang, K. (eds) Advanced Manufacturing and Automation XI. IWAMA 2021. Lecture Notes in Electrical Engineering, vol 880. Springer, Singapore. https://doi.org/10.1007/978-981-19-0572-8_30

Download citation

DOI: https://doi.org/10.1007/978-981-19-0572-8_30

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-0571-1

Online ISBN: 978-981-19-0572-8

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)