Abstract

Pyrochemical reprocessing has opted for the reprocessing of spent metallic fuels from future sodium-cooled fast breeder reactors in India. Pyrochemical reprocessing involves several unit operations with various atmospheres at different temperatures ranging from 500 to 1500 °C. The primary separation process of the pyrochemical reprocessing is the electrorefining step. The electrorefining process uses molten LiCl–KCl eutectic salt as the electrolyte at 500 °C under an inert atmosphere for the separation of the fuel elements from spent fuel. Molten salts at high temperature are more corrosive to the structural materials. Hence, structural materials should possess high corrosion resistance in molten salt. Recent corrosion evaluation of various structural materials like stainless steels, Cr–Mo steels, Ni-based alloys, and graphite carried out was investigated in molten salt system. The possible and various types of corrosion mitigation strategies have adopted and test protocols for the molten salt corrosion protection are discussed. Thermal spray ceramic coatings as one of the best chemical barriers for the protection of materials from molten salts are highlighted. The mechanism of molten salt corrosion, the corrosion resistance behaviour of various candidate structural materials in LiCl–KCl molten salt, its mitigation by providing ceramic coatings for pyrochemical reprocessing applications are briefly discussed. All the structural materials tested in LiCl–KCl are found to be corrosive and the ceramic coated materials showed excellent corrosion resistance in the molten salt atmosphere.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Nagarajan K, Reddy BP, Ghosh S, Ravisankar G, Mohandas KS, Kamachi Mudali U, Kutty KVG, Viswanathan KVK, Babu CA, Kalyanasundaram P, Vasudeva Rao PR, Raj B (2011) Development of pyrochemical reprocessing for spent metal fuels. Energy Procedia 7:431–436

Nishimura TKT, Iizuka M, Tanaka H (1998) Development of an environmentally benign reprocessing technology—pyrometallurgical reprocessing technology. Prog Nucl Energy 32:381–387

Toth LM, Bond WD, Avens LR (1993) Aqueous and pyrochemical reprocessing of actinide fuels. JOM 45:35–39

Jagadeeswara Rao Ch, Ningshen S, Mallika C, Kamachi Mudali U (2018) Molten salt corrosion behavior of structural materials in LiCl-KCl-UCl3 by thermogravimetric study. J Nucl Mater 501:189–199

Kamachi Mudali U, Ravishankar A, Ningshen S, Suresh G, Sole R, Thyagarajan K (2011) Materials development and corrosion issues in the back end of fuel cycle. Energy Procedia 7:468–473

Reddy RG (2011) Molten salts: thermal energy storage and heat transfer media. J Phase Equilib Diffus 32:269

Nunes VMB, Queirós CS, Lourenço MJV, Santos FJV, Nieto de Castro CA (2016) Molten salts as engineering fluids—a review: Part I molten alkali nitrates. Appl Energy 183:603–611

Kuchibhotla A, Banerjee D, Dhir V (2020) Forced convection heat transfer of molten salts: a review. Nucl Eng Des 362:110591

Delpech S, Cabet C, Slim C, Picard GS (2010) Molten fluorides for nuclear applications. Mater Today 13:34–41

Le Brun C (2007) Molten salts and nuclear energy production. J Nucl Mater 360:1–5

Sridharan K, Allen TR (2013) 12—corrosion in molten salts. In: Lantelme F, Groult H (eds) Molten salts chemistry. Elsevier, Oxford, pp 241–267

Fernández AG, Cabeza LF (2020) Corrosion evaluation of eutectic chloride molten salt for new generation of CSP plants. Part 1: thermal treatment assessment. J Energy Storage 27:101125

Matthew Kurley PWHJ, McAlister A, Raiman S, Dai S, Mayes RT (2019) Enabling chloride salts for thermal energy storage: implications of salt purity. RSC Adv 9:25602–25608

Guo S, Zhang J, Wu W, Zhou W (2018) Corrosion in the molten fluoride and chloride salts and materials development for nuclear applications. Prog Mater Sci 97:448–487

Kane RD (2003) Molten salt corrosion. In: Covino BS, Cramer SD Jr (ed) Corrosion: fundamentals, testing, and protection. ASM International, pp 216–219

Harper MA, Lai GY (2001) Nickel based alloys for resistance to high temperature corrosion. In Jones RH (ed) Environmental effects on engineered materials. Marcel Decker, New York, 2001, pp 72–106

Jagadeeswara Rao Ch, Ningshen S (2020) High temperature molten salt corrosion of structural materials in UCl3–LiCl–KCl. Corros Eng Sci Technol 55:425–433

Seybolt AU (1970) Oxidation of Ni-20 Cr alloy and stainless steels in the presence of chlorides. Oxid Met 2:119–143

Raiman SS, Lee S (2018) Aggregation and data analysis of corrosion studies in molten chloride and fluoride salts. J Nucl Mater 511:523–535

Feng XK, Melendres CA (1982) Anodic corrosion and passivation behavior of some metals in molten LiCl–KCl containing qxide ions. J Electrochem Soc 129:1245–1249

Wang L, Li B, Shen M, Li S-Y, Yu J-G (2012) Corrosion resistance of steel materials in LiCl-KCl melts. Int J Miner Metall Mater 19:930–933

Barraza-Fierro JI, Espinosa-Medina MA, Hernandez-Hernandez M, Liu HB, Sosa-Hernandez E (2012) Effect of Li and Cu addition on corrosion of Fe–40at.% Al intermetallics in molten LiCl–KCl eutectic salt. Corros Sci 59:119–126

Sim J-H, Kim Y-S, Cho I-J (2017) Corrosion behavior induced by LiCl-KCl in type 304 and 316 stainless steel and copper at low temperature. Nucl Eng Technol 49:769–775

Horvath D, Simpson MF (2018) Electrochemical monitoring of Ni corrosion induced by water in eutectic LiCl-KCl. J Electrochem Soc 165:C226–C233

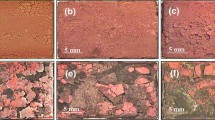

Ravishankar A, Thyagarajan K, Kamachi Mudali U (2013) Corrosion behavior of candidate materials in molten LiCl-KCl salt under argon atmosphere. Corrosion 69:655–665

Ravishankar A, Kamachi Mudali U (2008)Corrosion of type 316L stainless steel in molten LiCl-KCl salt. Mater Corros 59:878–882

Ravishankar A, Kanagasundar A, Kamachi Mudali U (2013) Corrosion of nickel-containing alloys in molten LiCl-KCl medium. Corrosion 69:48–57

Sure J, Ravi Shankar A, Ramya S, Mallika C, Kamachi Mudali U (2014) Corrosion behaviour of carbon materials exposed to molten lithium chloride–potassium chloride salt. Carbon 67:643–655

Sure J, Ravishankar A, Kamachi Mudali U, Nowicki A, Raj B (2013) Characterisation of pyrolytic graphite exposed to molten LiCl–KCl salt. Surf Eng 29:28–33

Jagadeeswara Rao Ch, Ravishankar A, Ajikumar PK, Kamruddin M, Mallika C, Kamachi Mudali U (2015) Corrosion behavior of structural materials in LiCl-KCl molten salt by thermogravimetric study. Corrosion 71:502–509

Nishikata A, Haruyama S (1986) Electrochemical monitoring of the corrosion of Ni Fe, and their alloys in molten salts. Corrosion 42:578–584

Cuevas-Arteaga C (2008) Corrosion study of HK-40m alloy exposed to molten sulfate/vanadate mixtures using the electrochemical noise technique. Corros Sci 50:650–663

Cuevas-Arteaga C, Uruchurtu-Chavarín J, González J, Izquierdo-Montalvo G, Porcayo-Calderón J, Cano-Castillo U (2004) Corrosion evaluation of Alloy 800 in sulfate/vanadate molten salts. Corrosion 60:548–560

Sanchez-Carrillo M, Trinstancho-Reyes JL, Sandoval-Jabalera R, Orozco-Carmona VM, Almeraya-CalderónF, Chacón-Nava JG, Gonzalez-Rodriguez JG, Martínez-Villafañe A (2011) Electrochemical impedance spectroscopy investigation of alloy inconel 718 in molten salts at high temperature. Int J Electrochem Sci 6:419–431

Mohammadi Zahrani E, Alfantazi AM (2012) Corrosion behavior of alloy 625 in PbSO4-Pb3O4-PbCl2-ZnO-10 Wt Pct CdO molten salt medium. Metall Mater Trans A 43:2857–2868

Nishikata A, Numata H, Tsuru T (1991) Electrochemistry of molten salt corrosion. Mater Sci Eng, A 146:15–31

Salinas-Solano G, Porcayo-Calderon J, Gonzalez-Rodriguez JG, Salinas-Bravo VM, Ascencio-Gutierrez JA, Martinez-Gomez L (2014) High temperature corrosion of inconel 600 in NaCl-KCl molten salts. Adv Mater Sci Eng 2014:8

Jagadeeswara Rao Ch, Venkatesh P, Ningshen S (2019) Corrosion assessment of 9Cr-1Mo steel in molten LiCl-KCl eutectic salt by electrochemical methods. J Nucl Mater 514:114–122

Zhang J, Forsberg CW, Simpson MF, Guo S, Lam ST, Scarlat RO, Carotti F, Chan KJ, Singh PM, Doniger W, Sridharan K, Keiser JR (2018) Redox potential control in molten salt systems for corrosion mitigation. Corros Sci 144:44–53

Sadeghi E, Markocsan N, Joshi S (2019) Advances in corrosion-resistant thermal spray coatings for renewable energy power plants Part I: effect of composition and microstructure. J Therm Spray Technol 28:1749–1788

Agüero A, Audigié P, Rodríguez S, Encinas-Sánchez V, Miguel MTD, Pérez FJ (2018) Protective coatings for high temperature molten salt heat storage systems in solar concentration power plants. In: AIP conference proceedings, vol 2033, p 090001

Jafari R, Sadeghimeresht E, Farahani TS, Huhtakangas M, Markocsan N, Joshi S (2018) KCl-induced high-temperature corrosion behavior of HVAF-sprayed Ni-based coatings in ambient air. J Therm Spray Technol 27:500–511

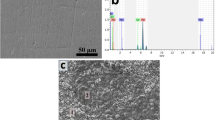

Ravishankar A, Kamachi Mudali U, Sole R, Khatak HS, Raj B (2008) Plasma-sprayed yttria-stabilized zirconia coatings on type 316L stainless steel for pyrochemical reprocessing plant. J Nucl Mater 372:226–232

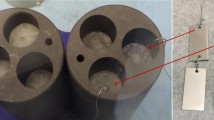

Sure J, Jagadeeswara Rao Ch, Venkatesh P, Prabhakara Reddy B, Mallika C, Kamachi Mudali U (2014) Evaluation of plasma sprayed alumina–40wt% titania and partially stabilized zirconia coatings on high density graphite for uranium melting application. Ceram Int 40:6509–6523

Sure J, Ravishankar A, Ramya S, Kamachi Mudali U (2012) Molten salt corrosion of high density graphite and partially stabilized zirconia coated high density graphite in molten LiCl–KCl salt. Ceram Int 38:2803–2812

Sure J, Mallika C, Choubey A, Kamachi Mudali U (2016) Corrosion behavior of laser melted alumina–40 wt% titania coated high density graphite in molten salt. Trans Indian Inst Metals 69:1633–1644

Jagadeeswara Rao Ch, Venkatesh P, Prabhakara Reddy B, Ningshen S, Mallika C, Kamachi Mudali U (2017) Corrosion behavior of yttria-stabilized zirconia-coated 9Cr-1Mo steel in molten UCl3-LiCl-KCl salt. J Therm Spray Technol 26:569–580

Jagadeeswara Rao Ch, Madhura B, Vetrivendan E, Thyagarajan K, Ningshen S, Mallika C, Kamachi Mudali U (2018) Molten salt corrosion resistance of yttria stabilized zirconia coating with silicon carbide interlayer on high density graphite. Trans Indian Inst Metals 71:1237–1245

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Jagadeeswara Rao, C., Ningshen, S., Kamachi Mudali, U. (2022). Molten Salt Corrosion and Its Mitigation for Pyrochemical Reprocessing Applications. In: Kamachi Mudali, U., Subba Rao, T., Ningshen, S., G. Pillai, R., P. George, R., Sridhar, T.M. (eds) A Treatise on Corrosion Science, Engineering and Technology. Indian Institute of Metals Series. Springer, Singapore. https://doi.org/10.1007/978-981-16-9302-1_12

Download citation

DOI: https://doi.org/10.1007/978-981-16-9302-1_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-9301-4

Online ISBN: 978-981-16-9302-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)