Abstract

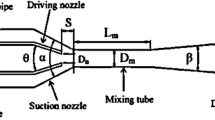

Check valves are responsible for regulating and controlling the direction of flow in various systems. The Tesla-type check valve (TTCV) is one kind of passive-type check valve with a regulating performance influenced by its fixed geometry. The main evaluation criterion to quantify the regulating performance is diodicity (Di). In this article, aiming for improving the Di, a surrogate-model based methodology is presented for optimizing the geometric parameters of the TTCV. The length of the straight segment of the side-channel, the angle between the side-channel and the main-channel, the angle between the tangent of the inner curve and the main-channel, and channel width are selected as design variables for searching an optimum design. To obtain a suitable surrogate model for this case, different surrogate models, such as polynomial response surface (PRS), Kriging (KRG), support vector regression (SVR), and radial basis function (RBF), which have been widely used for a variety of engineering problems, are compared in this study. A derivative-free global optimum algorithm, the Genetic Algorithm (GA), is adopted for achieving a global optimum. The improvement in TTCV is analyzed and the optimization results are validated to confirm the effectiveness and feasibility of the proposed methodology. It is found that compared with the existing optimum design, the Di of the predicted optimum design still has an improvement of 4.32%. The proposed methodology may facilitate improvements in the design and optimization of the TTCV, thus benefiting the development of fluid transport techniques in micro- or mini-channel systems.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Knutson, A.L., Van de Ven, J.D.: Modelling and experimental validation of the displacement of a check valve in a hydraulic piston pump. Int. J. Fluid Power 17(2), 114–124 (2016)

Nikola, T.: Valvular conduit. U.S. Patent 1329559. 1920-2-3

Forster, F.K., Bardell, R.L., Afromowitz, M.A., et al.: Design, fabrication and testing of fixed-valve micro-pumps. Asme-Publications-Fed 234, 39–44 (1995)

Thompson, S.M., Paudel, B., Jamal, T., et al.: Numerical investigation of multistaged tesla valves. J. Fluids Eng. 136(8), 081102 (2014)

Truong, T.Q., Nguyen, N.T.: Simulation and optimization of tesla valves. Nanotech 1, 178–181 (2003)

Anagnostopoulos, J.S., Mathioulakis, D.S.: Numerical simulation and hydrodynamic design optimization of a tesla-type valve for micropumps. Iasme Trans. (2005)

Zhang, S., Winoto, S.H., Low, H.T.: Performance simulations of Tesla microfluidic valves. Int. Conf. Integr. Commercialization Micro Nanosyst. 42657, 15–19 (2007)

Thompson, S.M., Ma, H.B., Wilson, C.: Investigation of a flat-plate oscillating heat pipe with Tesla-type check valves. Exp. Therm. Fluid. 35(7), 1265–1273 (2011)

Nobakht, A.Y., Shahsavan, M., Paykani, A.: Numerical study of diodicity mechanism in different Tesla-type microvalves. J. Appl. Res. Technol. 11(6), 876–885 (2013)

Mohammadzadeh, K., Kolahdouz, E.M., Shirani, E., et al.: Numerical investigation on the effect of the size and number of stages on the Tesla microvalve efficiency. J. Mech. 29(3), 527–534 (2013)

Thompson, S.M., Jamal, T., Paudel, B.J., et al.: Transitional and turbulent flow modeling in a Tesla valve. ASME Int. Mech. Eng. Congr. Exposition (2013)

de Vries, S.F.D., Florea, D., Homburg, F.G.A., et al.: Design and operation of a Tesla-type valve for pulsating heat pipes. Int. J. Heat Mass Transfer 105, 1–11 (2017)

Porwal, P.R., Thompson, S.M., Walters, D.K., et al.: Heat transfer and fluid flow characteristics in multistaged Tesla valves. Numer. Heat Transfer Part A Appl. 73(6), 347–365 (2018)

Zhi-jiang, J.I.N., Zhi-xin, G.A.O., Min-rui, C.H.E.N., et al.: Parametric study on Tesla valve with reverse flow for hydrogen decompression. Int. J. Hydrogen Energy 43(18), 8888–8896 (2018)

Jin-yuan, Q.I.A.N., Jia-yi, W.U., Zhi-xin, G.A.O., et al.: Hydrogen decompression analysis by multi-stage Tesla valves for hydrogen fuel cell. Int. J. Hydrogen Energy 44(26), 13666–13674 (2019)

Qian, J., Chen, M., Liu, X., et al.: A numerical investigation of the flow of nanofluids through a micro Tesla valve. J. Zhejiang Univ. Sci. A 20(1), 50–60 (2019)

Yang, R.J., Akkerman, A., Anderson, D.F., et al.: Robustness optimization for vehicular crash simulations. Comput. Sci. Eng. 2(6), 8–13 (2000)

Jin, R., Chen, W., Simpson, T.W.: Comparative studies of metamodelling techniques under multiple modelling criteria. Struct. Multidiscip. Optim. 23(1), 1–13 (2001)

Hussain, M.F., Barton, R.R., Joshi, S.B.: Metamodeling: Radial basis functions, versus polynomials. Eur. J. Oper. Res. 138(1), 142–154 (2002)

Simpson, T.W., Booker, A.J., Ghosh, D., et al.: Approximation methods in multidisciplinary analysis and optimization: A panel discussion. Struct. Multidiscip. Optim. 27(5), 302–313 (2004)

Lanzi, L., Castelletti, L.M.L., Anghileri, M.: Multi-objective optimisation of composite absorber shape under crashworthiness requirements. Compos. Struct. 65(3/4), 433–441 (2004)

Yang, R.J., Gu, L.: Experience with approximate reliability-based optimization methods. Struct. Multidiscip. Optim. 26(1–2), 152–159 (2004)

Yang, R.J., Chuang, C., Gu, L., et al.: Experience with approximate reliability-based optimization methods II: An exhaust system problem. Struct. Multidiscip. Optim. 29(6), 488–497 (2005)

Yang, R.J.: Metamodeling development for vehicle frontal impact simulation. ASME Des. Eng. Tech. Conf. (2001)

Lee, K.H., Kang, D.H.: Structural optimization of an automotive door using the Kriging interpolation method. Proc. Inst. Mech. Eng. Part D J. Automobile Eng. 221(12), 1525–1534 (2007)

Xing-tao, L.I.A.O., Qing, L.I., Xu-jing, Y.A.N.G., et al.: Multiobjective optimization for crash safety design of vehicles using stepwise regression model. Struct. Multidiscip. Optim. 35(6), 561–569 (2007)

Xing-tao, L.I.A.O., Qing, L.I., Xu-jing, Y.A.N.G., et al.: A two-stage multi-objective optimisation of vehicle crashworthiness under frontal impact. Int. J. Crashworthiness 13(3), 279–288 (2008)

Viana, F.A.C., Haftka, R.T., Steffen, V.: Multiple surrogates: How cross-validation errors can help us to obtain the best predictor. Struct. Multidiscip. Optim. 39(4), 439–457 (2009)

Song, X., Jung, J.H., Son, H.J., et al.: Metamodel-based optimization of a control arm considering strength and durability performance. Comput. Math. Appl. 60(4), 976–980 (2010)

Xue-guan, S.O.N.G., Guang-yong, S.U.N., Guang-yao, L.I., et al.: Crashworthiness optimization of foam-filled tapered thin-walled structure using multiple surrogate models. Struct. Multidiscip. Optim. 47(2), 221–231 (2013)

Song, X., Lv, L., Li, J., et al.: An advanced and robust ensemble surrogate model: Extended adaptive hybrid functions. J. Mech. Des. (2018)

Tan, H., Wu, L., Wang, M., et al.: Heat transfer improvement in microchannel heat sink by topology design and optimization for high heat flux chip cooling. Int. J. Heat Mass Transfer 129(Feb.), 681–689 (2019)

Jin, R., Chen, W., Sudjitanto, A.: On sequential sampling for global metamodeling in engineering design. Det02: ASME Des. Eng. Tech. Conf. Comput. Inf. Eng. Conf. (2002)

Myers, R.H., Montgomery, D.C., Anderson-Cook, C.M.: Response surface methodology: process and product optimization using designed experiments. Wiley (2016)

Sacks, J., Welch, W.J., Mitchell, T.J., et al.: Design and analysis of computer experiments. Stat. Sci. 409–423 (1989)

Smola, A.J., Schölkopf, B.: A tutorial on support vector regression. Stat. Comput. 14(3), 199–222 (2004)

Guang-yong, S.U.N., Guang-yao, L.I., Zhi-hui, G.O.N.G., et al.: Radial basis functional model for multi-objective sheet metal forming optimization. Eng. Optim. 43(12), 1351–1366 (2011)

Han, Z., Zhang, K.: Surrogate-based optimization. In: Real-World Applications of Genetic Algorithms. InTech (2012)

Ozcanan, S., Atahan, A.O.: RBF surrogate model and EN1317 collision safety-based optimization of two guardrails. Struct. Multidiscip. Optim. (2019)

Goel, T., Haftka, R.T., Shyy, W., et al.: Ensemble of surrogates. Struct. Multidiscip. Optim. 33(3), 199–216 (2007)

Wang, G.G., Shan, S.: Review of Metamodeling Techniques in Support of Engineering Design Optimization (2007)

Olsson, A., Sandberg, G., Dahlblom, O.: On Latin hypercube sampling for structural reliability analysis. Struct. Saf. (2003)

Li, W., Peng, X., Xiao, M., et al.: Multi‐objective design optimization for mini‐channel cooling battery thermal management system in an electric vehicle. Int. J. Energy Res. (2019)

Arora, J.S.: Introduction to Optimum Design. Elsevier (2004)

Acknowledgements

This project is supported by National Key R&D Program of China (Grant No. 2018YFB1700704), National Natural Science Foundation of China (Grant No. 52075068).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Li, K., Wang, S., Zong, C., Liu, Y., Song, X. (2022). Diodicity Optimization of Tesla-Type Check Valve Based on Surrogate Modeling Techniques. In: Tan, J. (eds) Advances in Mechanical Design. ICMD 2021. Mechanisms and Machine Science, vol 111. Springer, Singapore. https://doi.org/10.1007/978-981-16-7381-8_76

Download citation

DOI: https://doi.org/10.1007/978-981-16-7381-8_76

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7380-1

Online ISBN: 978-981-16-7381-8

eBook Packages: EngineeringEngineering (R0)