Abstract

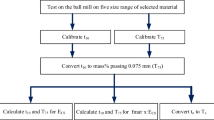

In this chapter, the mechanism and factors affecting size reduction process and the laws governing these operations are discussed. Size reduction is a process in which particles with smaller size and large surface areas are formed, which ultimately eases the processing. The chapter explains the size reduction mechanism during compression, impact, cutting, shearing, and attrition. The stress-strain behavior of materials during mechanical failure also plays an important role during size reduction. To evaluate the effectiveness of size reduction operation, analysis of newly formed surfaces and energy involved becomes important. A better understanding of equipment and operation parameters can minimize the overall input energy. The popular size reduction equipments for agricultural produce, viz., hammer mill, ball mill, burr mill, jaw crusher, gyratory crusher, crushing roll, cutter mill, Reitz mill, and colloid mills, are explained using schematic diagrams. The heat generated during size reduction is always a big concern in processing spices and herbs. Hence, advanced size reduction operations like hammer mill with water jackets and cryogenic grinding are used to protect the aromatic and volatile components. In liquid food, homogenization is frequently used to break particulate matter into smaller and uniform particle sizes to form dispersion. The chapter also deals with different size reduction laws.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Fellow, P. J. (2000). Food processing technology principles and practices (2nd ed.). Woodhead Publishing Limited.

Earle, R. L. (2013). Unit operations in food processing. Elsevier.

Schneider, Y., Zahn, S., & Linke, L. (2002). Qualitative process evaluation for ultrasonic cutting of food. Engineering in Life Sciences, 2(6), 153–157.

Mohsenin, N. N. (1977). Characterization and failure in solid foods with particular reference to fruits and vegetables. Journal of Texture Studies, 8(2), 169–193.

Henderson, S. M., & Perry, R. L. (1976). Agriculture process engineering. AVI Publishing.

McCabe, W. L., Smith, J. C., & Harriot, P. (2014). Unit operation of chemical engineering. McGraw Hill Education (India) Edition. McGraw Hill Education (India) Private Limited.

Sahay, K.M. and Singh, K.K. (2001). Unit operation of agriculture processing (2nd revised ed.). Vikas Publishing House Pvt. Ltd.

Saravacos, G. D., & Kostaropoulos, A. E. (2002). Handbook of food processing equipment. Kluwer Academic/Plenum Publishers.

Brennan, J. G., Butters, J. R., Cowell, N. D., & Lilly, A. E. V. (1969). Food engineering operations. Elsevier.

Snow, R. H., Kaye, B. H., Capes, C. E., & Sresty, G. C. (1984). Size reduction and size enlargement. Microscope, 20, 8.

Shelake, P. S., Dabhi, M. N., Sabat, M., & Rathod, P. J. (2019). Performance evaluation of developed low-temperature grinding mill. Journal of Food Process Engineering, 42(8), e13290.

Singh, K. K., & Goswami, T. K. (1999). Studies on cryogenic grinding of cumin seed. Journal of Food Process Engineering, 22(3), 175–190.

Brennan, J. G. (2006). Mixing, emulsification and size reduction. In Food processing handbook (p. 513). Wiley-VCH.

Handbook, A. H. (2009). Processing of emulsions and dispersions (pp. 1–23). SPX Corporation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Kumar, Y., Sharanagat, V.S., Kumar, K. (2022). Size Reduction. In: Sharma, H.K., Kumar, N. (eds) Agro-Processing and Food Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-7289-7_6

Download citation

DOI: https://doi.org/10.1007/978-981-16-7289-7_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7288-0

Online ISBN: 978-981-16-7289-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)