Abstract

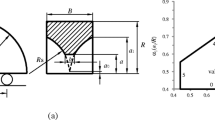

Two new designs of fracture specimens that work under compressive loading are introduced in the form of a circular ring with two collinear cracks emanating from inner edge and that from outer edge. The first configuration can be thought of as Brazilian disk with a central hole smaller than its central crack. Due to the absence of material at the center in the ring specimen, the normal stress-causing opening of prospective crack is more than that for the disk specimen. The finite element method (FEM) was used to model and solve the ring configuration as an elasticity problem. Displacement extrapolation method was used to extract fracture parameters in the post-processing. Parametric analysis was conducted on the mode I stress intensity factor, which was computed for different crack lengths and ratios of inner to outer radii. The numerical results show that the double edge cracked circular ring specimen has an enhanced stress intensity factor comparing with that of Brazilian disk. The ring specimen can be extended for mixed-mode testing.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zhu X-K, Joyce JA (2012) Review of fracture toughness (G, K, J, CTOD, CTOA) testing and standardization. Engng Fract Mech 85:1–46

Atkinson C, Smelser RE, Sanchez J (1982) Combined mode fracture via the cracked Brazilian disk test. Int J Fract 18(4):279–291

Lim IL, Johnston IW, Choi SK, Boland JN (1994) Fracture testing of a soft rock with semi-circular specimens under three-point bending Part l: Mode-I. Int J Rock Mech Min Sci Geomech Abstr 31(3):185–197

Bui HD, Maigre H, Rittel D (1992) A new approach to the experimental determination of the dynamic stress intensity factor. Int J Solids Struct 29(23):2881–2895

Underwood JH, Kendall DP (1976) Fracture toughness testing using the C-shaped specimen. Technical Report WVT-TR-76027, Benet weapons laboratory, Rock Island, Illinois-61201, July 1976

Ayatollahi MR, Aliha MRM (2009) Analysis of a new specimen for mixed mode fracture tests on brittle materials. Eng Fract Mech 76:1563–1573

Fett T (2001) Stress intensity factors and T-stress for internally cracked circular disks under various boundary conditions. Eng Fract Mech 68(9):1119–1136

Chen F, Sun Z, Xu J (2001) Mode I fracture analysis of the double edge cracked Brazilian disk using a weight function method. Int J Rock Mech Mining Sci 38:475–479

Dong S, Wang Y, Xia Y (2006) A finite element analysis for using Brazilian disk in split Hopkinson pressure bar to investigate dynamic fracture behaviour of brittle polymer materials. Polym Test 25:943–952

Ayatollahi MR, Aliha MRM (2008) On the use if Brazilian disc specimen for calculating mixed mode I-II fracture toughness of rock materials. Eng Fract Mech 75:4632–4641

Tang SB (2017) Stress intensity factor for a Brazilian disc with a central crack subjected to compression. Int J Rock Mech Mining Sci 93:38–45

Tracy PG (1975) Analysis of a radial crack in a circular ring segment. Eng Fract Mech7(Mmc):253–260

Bowie OL, Freese CE (1972) Elastic analysis for a radial crack in a circular ring. Eng Fract Mech 4(2):315–321

Ahmed J, Ashbough NE (1982) Constant KI crack propagation test specimen. Int J Fract 19:115–129

Leung AYT, Hu JD (1997) Mode II stress intensity factors for a circular ring or a hollow cylinder with a radial crack. Int J Press Vessels Piping 72(2):149–156

Timoshenko SP, Goodier JN (1970) Theory of elasticity, 3rd ed. McGraw-Hill Book Company

Anderson T (2005) Fracture mechanics. Boca Raton. Taylor & Francis, FL

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mohammed Shafeeque, K.K., Surendra, K.V.N. (2022). Analysis of a Double Edge Cracked Circular Ring Under Diametrical Compression. In: Maiti, D.K., et al. Recent Advances in Computational and Experimental Mechanics, Vol II. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-6490-8_34

Download citation

DOI: https://doi.org/10.1007/978-981-16-6490-8_34

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6489-2

Online ISBN: 978-981-16-6490-8

eBook Packages: EngineeringEngineering (R0)